Ultrasound-assisted method and device for extracting nano-particles from nano-powder organic solvent suspension liquid

A nano-powder and suspension technology, which is applied in the fields of medical materials and industrial state detection, can solve problems such as difficult extraction, high viscosity and molecular entanglement, and achieve improved separation efficiency, accelerated degradation, and extraction and separation speed Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

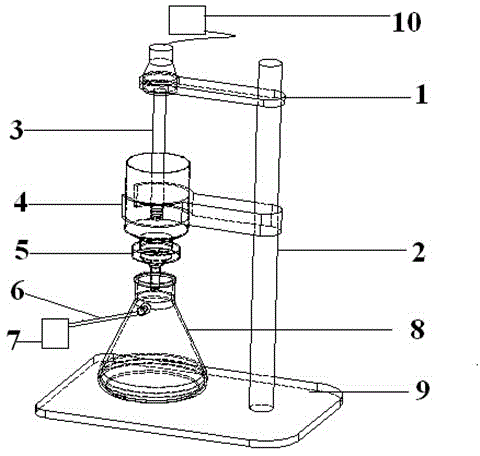

[0026] Example 1 Nano powder extraction and separation device

[0027] Such as figure 1 As shown, the extraction device of the present embodiment includes:

[0028] An ultrasonic system, which includes an ultrasonic power supply and an ultrasonic horn 3;

[0029] A filtration system comprising a filter cup 4 and a filter membrane 5, wherein the filter membrane 5 is fixed at the lower end of the filter cup 4, and the ultrasonic horn 3 is inserted into the filter cup 4;

[0030] Collecting system, it comprises collecting bottle 8, and is connected below the filtering system;

[0031] Vacuum filtration system, which comprises a vacuum pump 7 and a suction filter tube 6, wherein one end of the suction filter tube 6 is connected with the vacuum pump 7, and the other end of the suction filter tube 6 is connected with the collection bottle 8; and

[0032] The supporting part includes a clamp 1 , a bracket 2 and a base 9 , wherein the ultrasonic horn 3 and the filter cup 4 are fi...

Embodiment 2

[0033] Example 2 Extraction of Nano Ultra High Molecular Weight Polyethylene Debris from Suspension

[0034] Preparation of microparticle suspension: Ultra-high relative molecular weight polyethylene (UHMWPE) wear debris is selected, which is basically irregular spherical particles with a particle size range of 0.2-0.8 μm. The liquid medium is calf serum deionized water with a volume fraction of 25%. diluent, select ethanol as surfactant to reduce surface tension. A mixture of water and ethanol (the volume ratio of water and ethanol is 3:5) is added to the diluent as a dispersant to prepare a UHMWPE-bovine serum suspension. In the suspension, the mass concentration of UHMWPE is 0.5%. , the volume concentration of calf serum is 2.5%, the volume concentration of ethanol is 56.2%, and the balance is water.

[0035] Ultrasonic-assisted filtration: put 200ml of UHMWPE-bovine serum suspension into the filter cup (4), put the ultrasonic horn (3) into the suspension, turn on the ul...

Embodiment 3

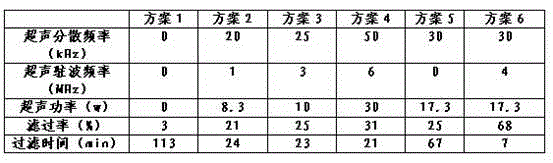

[0038] Embodiment 3 extracts nano-copper powder particle from suspension

[0039] The UHMWPE in embodiment 2 is replaced with copper abrasive dust, and test method is the same as embodiment 2, and concrete result is as follows

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com