Starting method for rapid and efficient short-cut nitrification

A short-range nitrification and high-efficiency technology, applied in the field of sewage treatment, can solve the problems of slow proliferation efficiency of ammonia oxidizing bacteria, long start-up period of short-range nitrification, low nitrite accumulation efficiency, etc. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

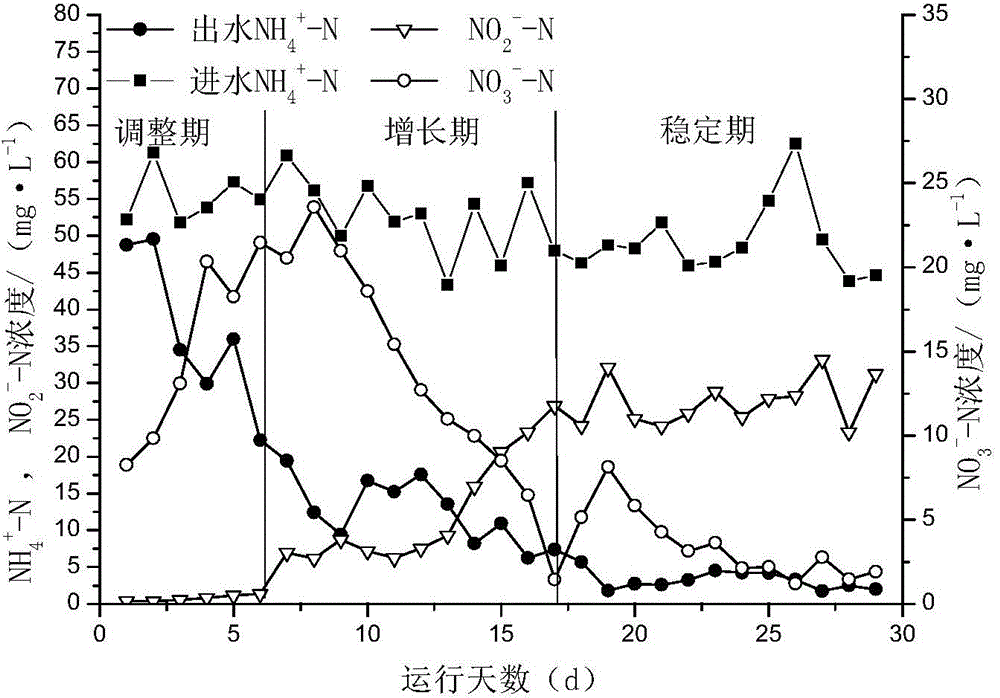

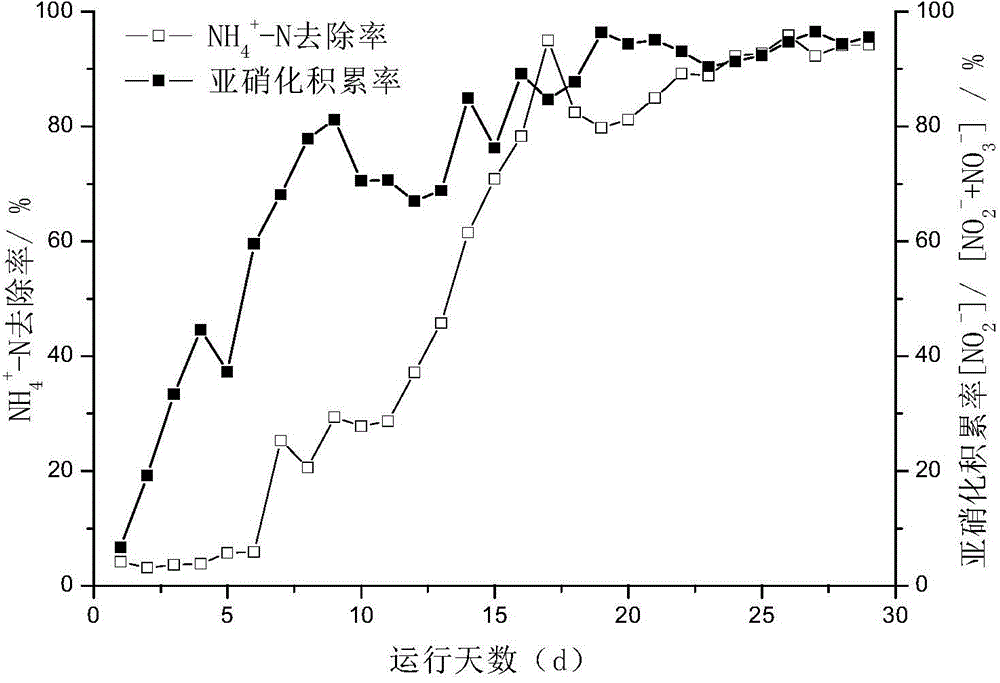

Embodiment 1

[0050] 1. The start of fast and efficient short-range nitrification includes the following steps:

[0051] 1) Introduce the inoculation sludge rich in nitrifying bacteria into the SBR reactor, the inoculation sludge is the return sludge of the secondary sedimentation tank of the municipal sewage plant; the concentration of the inoculation sludge MLSS is 4800mg / L; the reactor adopts intermittent operation mode;

[0052] 2) Inlet water: import the sewage to be treated into the SBR reactor, make the concentration of inoculated sludge MLSS in the previous step 3000mg / L, control the temperature of the sewage to 30±1°C, pH 8, and the chemical oxygen demand of the sewage to be treated COD is 170mg / L, ammonia nitrogen concentration is 50mg / L;

[0053] 3) Aeration: Start the aeration facility in the reactor to make the reactor an aerobic environment, in which the dissolved oxygen DO concentration is 1mg / L; the aeration time is 2h;

[0054] 4) Turn off the aeration facility and turn on...

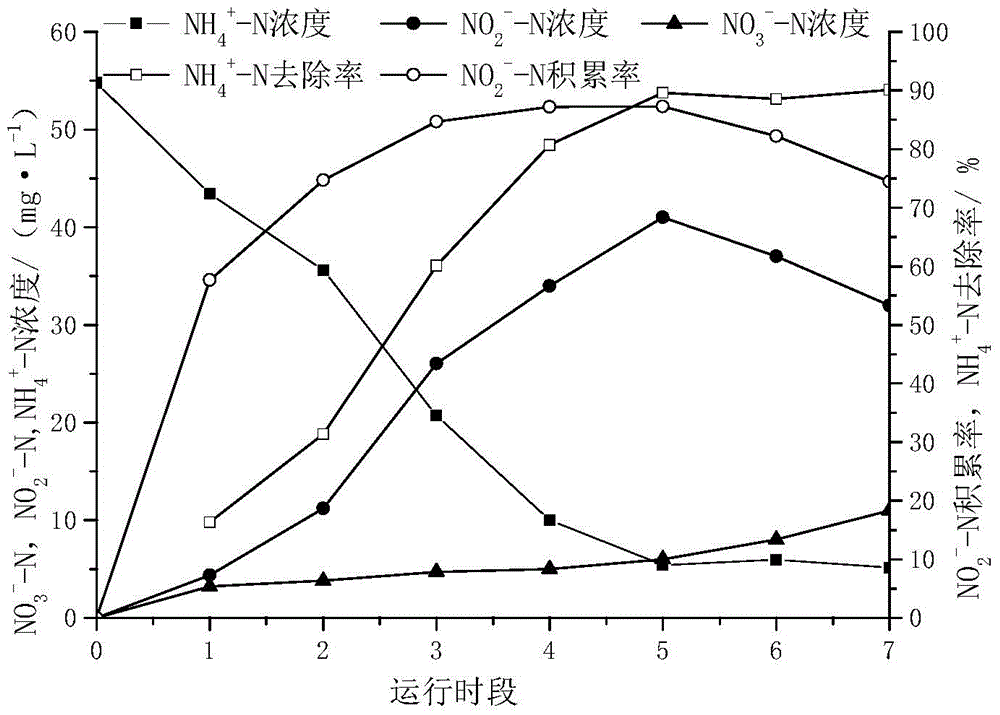

Embodiment 2

[0067] The start of fast and efficient short-cut nitrification includes the following steps:

[0068] 1) Introduce the inoculation sludge rich in nitrifying bacteria into the SBR reactor, the inoculation sludge is the return sludge of the secondary sedimentation tank of the municipal sewage plant; the concentration of the inoculation sludge MLSS is 4800mg / L; the reactor adopts intermittent operation mode;

[0069] 2) Influent water: import the sewage to be treated into the SBR reactor, so that the inoculation sludge concentration MLSS in the previous step is 3000mg / L, control the temperature of the sewage to be 30°C, pH 8.0, and the chemical oxygen demand COD of the sewage to be treated is 150mg / L, ammonia nitrogen concentration is 40mg / L;

[0070] 3) Aeration: Start the aeration facility in the reactor to make the reactor an aerobic environment, in which the dissolved oxygen DO concentration is 1mg / L; the aeration time is 2h;

[0071] 4) Turn off the aeration facility and tu...

Embodiment 3

[0076] The start of fast and efficient short-cut nitrification includes the following steps:

[0077] 1) Introduce the inoculation sludge rich in nitrifying bacteria into the SBR reactor, the inoculation sludge is the return sludge of the secondary sedimentation tank of the urban sewage plant; the concentration of the inoculation sludge MLSS is 5000mg / L; the reactor adopts intermittent operation mode;

[0078] 2) Influent water: import the sewage to be treated into the SBR reactor, so that the inoculation sludge concentration MLSS in the previous step is 3500mg / L, control the temperature of the sewage to be 29°C, pH 7.9, and the chemical oxygen demand COD of the sewage to be treated is 200mg / L, ammonia nitrogen concentration is 60mg / L;

[0079] 3) Aeration: Start the aeration facility in the reactor to make the reactor an aerobic environment, in which the dissolved oxygen DO concentration is 1.2mg / L; the aeration time is 2.5h;

[0080] 4) Turn off the aeration facility and tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com