High-strength crack-resistant concrete material

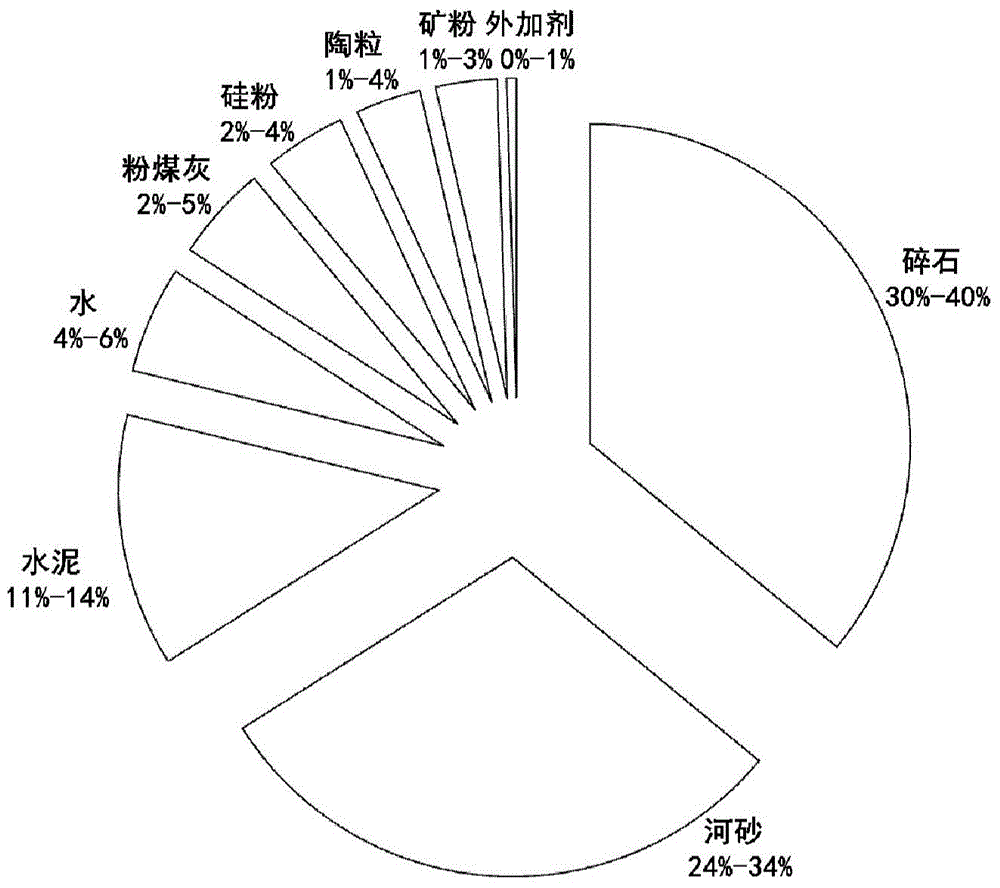

A concrete and high-strength technology, applied in the field of building materials, can solve the problems of reducing the effective cross-sectional area of the test piece, reducing the stiffness of structural members, reducing the strength of concrete, etc., achieving excellent frost resistance, eliminating early cracking, and preventing early cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] P.II52.5 cement: 312kg

[0036] Graded coarse aggregate stones: 798kg (the mass ratio of large stones to small stones is 0.8:1)

[0037] Ordinary washed river sand: 722kg

[0038] Fly ash: 104kg

[0039] Mineral powder: 52kg

[0040] Silica fume: 52kg

[0041] Water: 130kg

[0042] Pre-absorbed clay ceramsite: 60kg (coarse aggregate volume replacement rate is 20%; water content is 12kg)

[0043] Composite sulfamate superplasticizer: 14kg

[0044] First weigh 48kg of clay porous ceramsite, then weigh 12kg of ceramsite soaking water, and then fully mix the porous ceramsite and ceramsite soaking water. Add gravel, ceramsite and sand together and stir for 30 seconds; add cement and mineral admixtures and stir for 60 seconds; mix water and composite admixtures, add them to the mixer and stir for 120 seconds, observe the slump to pass the discharge .

[0045] After testing, the obtained high-strength crack-resistant concrete material (equivalent to strength grade C70)...

Embodiment 2

[0047] P.II52.5 cement: 332kg

[0048] Graded coarse aggregate stones: 783kg (the mass ratio of large stones to small stones is 1:1)

[0049] Ordinary washed river sand: 741kg

[0050] Fly ash: 52kg

[0051] Mineral powder: 52kg

[0052] Silica fume: 104kg

[0053] Water: 132kg

[0054] Pre-absorbed shale ceramsite: 45kg (coarse aggregate volume replacement rate is 14%; water content is 9kg)

[0055] Composite sulfamate superplasticizer: 17.7kg

[0056] First weigh 36kg of shale porous ceramsite, then weigh 9kg of ceramsite soaking water, and then fully mix the porous ceramsite and ceramsite soaking water. Add gravel, ceramsite and sand together and stir for 30 seconds; add cement and mineral admixtures and stir for 60 seconds; mix water and composite admixtures, add them to the mixer and stir for 120 seconds, observe the slump to pass the discharge .

[0057] After testing, the obtained high-strength crack-resistant concrete material (equivalent to strength grade C75)...

Embodiment 3

[0059] P.II52.5 cement: 345kg

[0060] Graded coarse aggregate stones: 771kg (the mass ratio of large stones to small stones is 1:1)

[0061] Ordinary washed river sand: 729kg

[0062] Fly ash: 38kg

[0063] Mineral powder: 38kg

[0064] Silica fume: 145kg

[0065] Water: 138kg

[0066] Pre-absorbed shale ceramsite: 35kg (coarse aggregate volume replacement rate is 11%; water content is 5kg)

[0067] Composite sulfamate superplasticizer: 19.3kg

[0068] First weigh 30kg of shale porous ceramsite, then weigh 5kg of ceramsite soaking water, and then fully mix the porous ceramsite and ceramsite soaking water. Add gravel, ceramsite and sand together and stir for 30 seconds; add cement and mineral admixtures and stir for 60 seconds; mix water and composite admixtures, add them to the mixer and stir for 120 seconds, observe the slump to pass the discharge .

[0069] After testing, the obtained high-strength crack-resistant concrete material (equivalent to strength grade C80)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com