Anticorrosion coating of precast pile foundation for silt soil complicated geology and method

A technology of complex geology and anti-corrosion coating, applied in sheet pile walls, foundation structure engineering, protective devices, etc., can solve the problems of pile foundation erosion, affecting the durability of structures, and greatly affecting the service life of buildings, so as to achieve enhanced durability Improvement in performance and construction efficiency, and the effect of excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

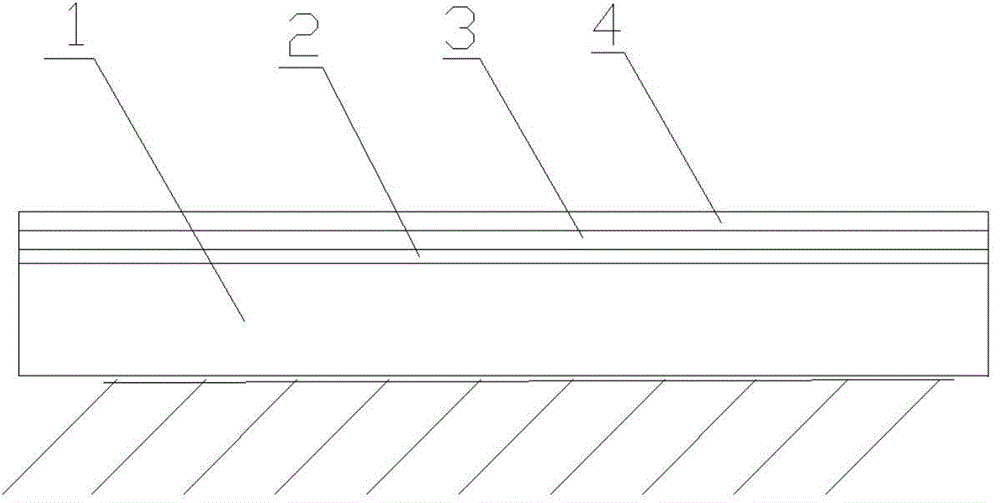

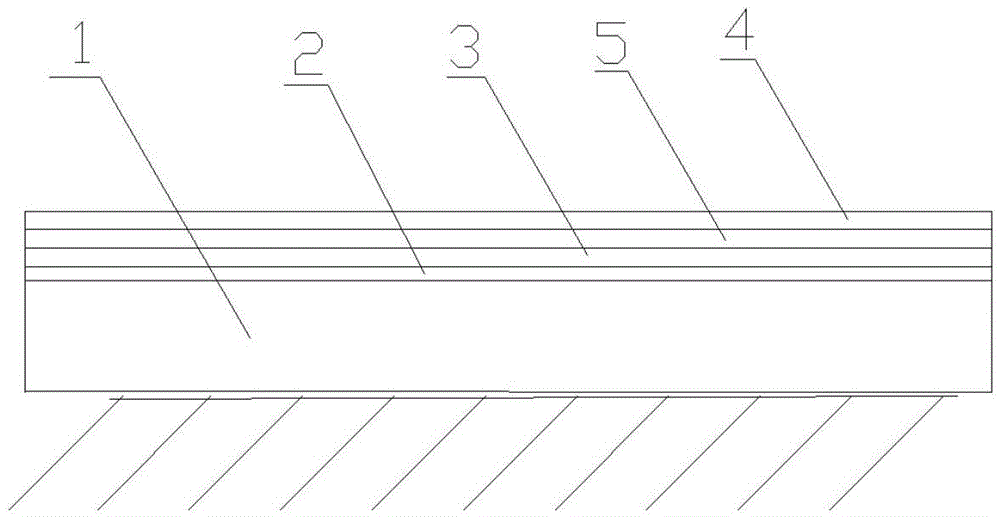

[0039] like figure 1 As shown, the prefabricated pile foundation anticorrosion coating of the present invention comprises a pile basic body 1, which is coated with an anticorrosion base layer 2 on the pile base body 1, and a polyurea elastic anticorrosion layer 3 is sprayed on the anticorrosion base layer 2, and the polyurea elastic anticorrosion layer The anticorrosion layer 3 is covered with a protective layer 4 of polymer reinforced mortar.

[0040] The construction process of the present invention is as follows:

[0041] Anti-corrosion material preparation and entry → anti-corrosion layer base treatment → primer construction → spraying polyurea anti-corrosion coating → spraying acceptance → protective layer construction → pile sinking construction.

[0042] Specific operation process:

[0043] 1. Material preparation and entry

[0044] 1. The finished products entering the site must be inspected and recorded according to the regulations. They can be used only after they...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com