Downdraft High Efficiency Finned Tube Biomass Boiler

A biomass boiler and finned tube technology, which is used in lighting and heating equipment, fluid heaters, water heaters, etc. Heat exchange efficiency, sufficient combustion, and the effect of reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

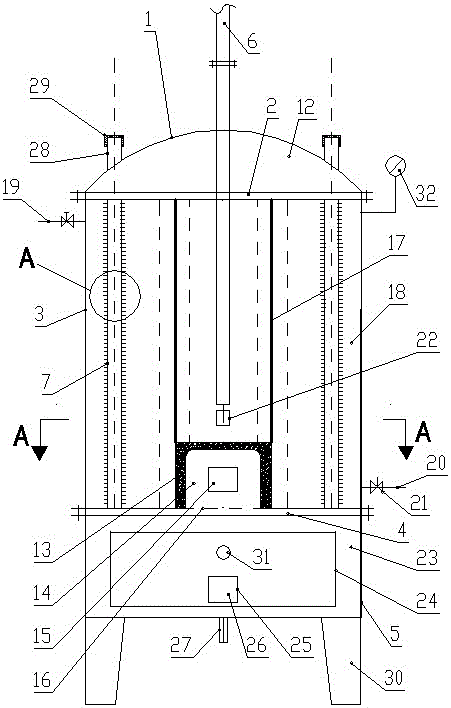

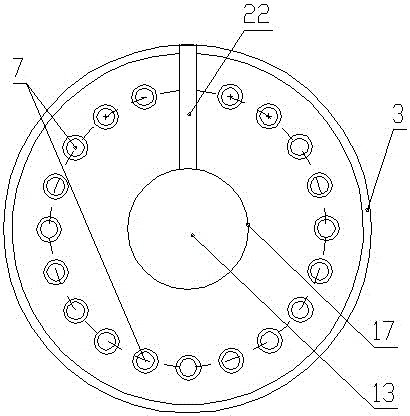

[0033] Such as Figure 1 to Figure 4 As shown, the down-draft high-efficiency finned tube biomass boiler of the present invention includes a drum 3, the drum 3 is in the shape of a cylinder, and an upper cover 1 and an upper head are sequentially arranged above the drum 3 from top to bottom. Structure 2. Below the drum 3, a lower head structure 4 and a lower furnace body 5 are sequentially arranged from top to bottom;

[0034] The cross section of the upper cover 1 is an arc with the top of the arc facing upward; a plurality of fin tubes 7 are evenly distributed in the circumferential direction in the drum 3, and the upper end of each fin tube 7 is connected with the upper head structure 2, and each fin The lower end of the sheet tube 7 is connected with the lower head structure 4.

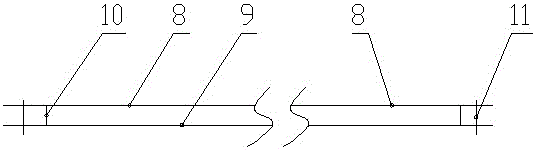

[0035] The upper head structure 2 and the lower head structure 4 both include a pair of upper orifice plate 8 and lower orifice plate 9 screwed together by bolts 11, and a sealing ring connected betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com