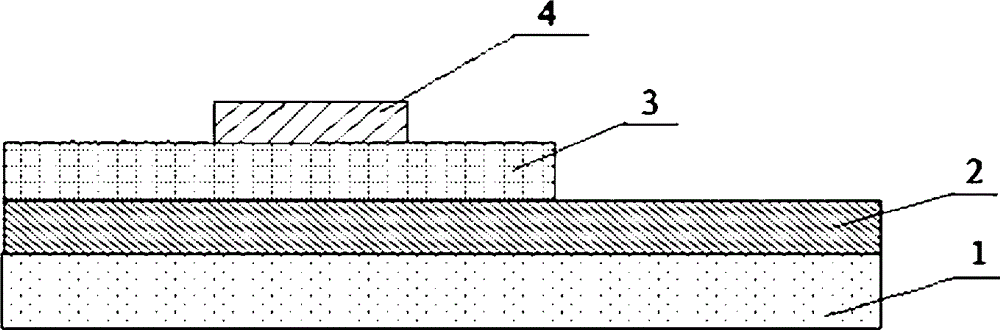

Full-transparent film voltage controlled varactor and preparation method thereof

A varactor, fully transparent technology, used in voltage-variable capacitors, ion implantation plating, coatings, etc., to achieve the effects of high transparency, good device stability, and high tuning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

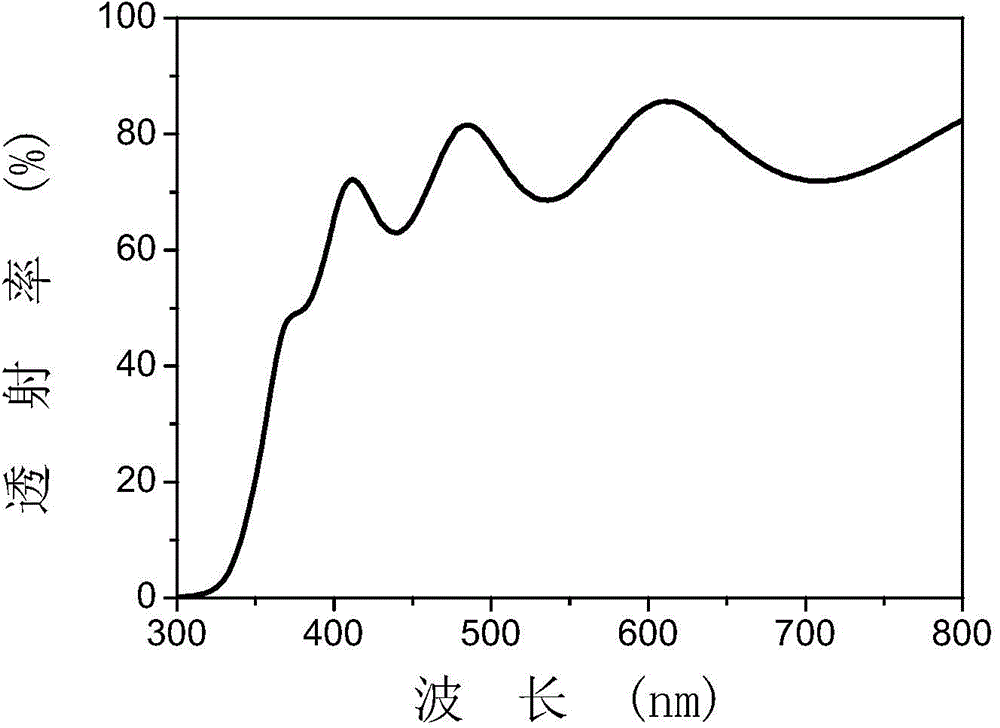

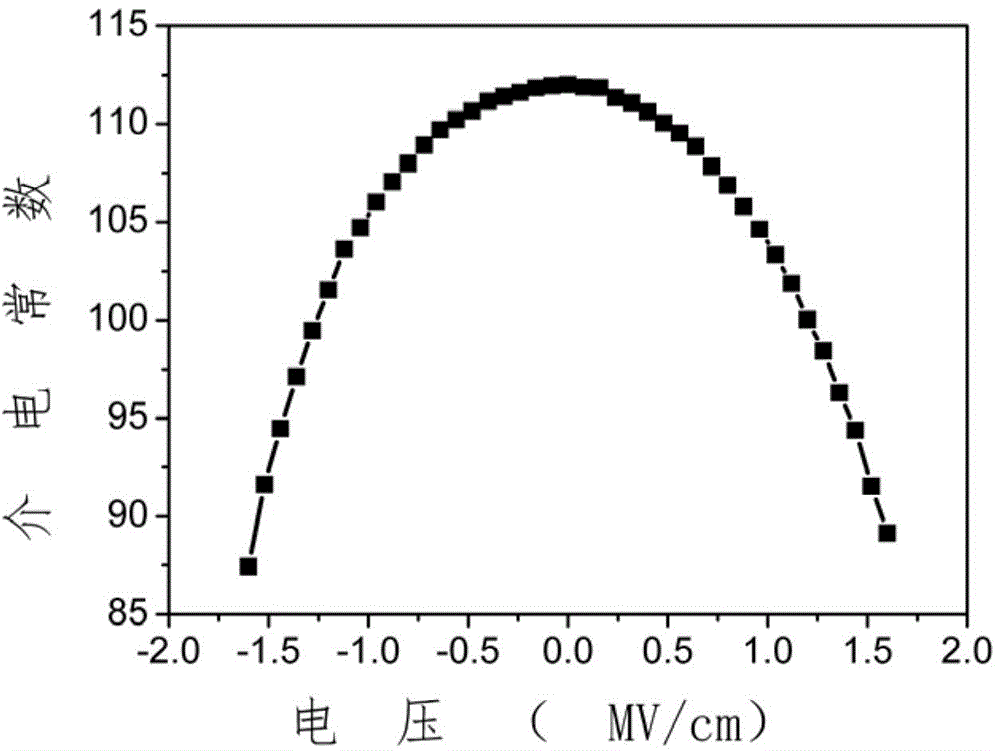

Embodiment 1

[0039] (1) Preparation of Ba by solid phase sintering method 0.6 Sr 0.4 TiO 3 Target and ITO target

[0040] Press Ba with electronic balance 0.6 Sr 0.4 TiO 3 The stoichiometric ratio of the corresponding elements weighs BaCO with a purity of 99%. 3 , SrCO 3 and TiO 2 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1450 ° C, and kept for 10 hours to obtain Ba 0.6 Sr 0.4 TiO 3 target;

[0041] Press Sn with electronic balance 0.03 In 0.97 O, the stoichiometric ratio of the corresponding elements Weigh SnO with a purity of 99.99% 2 and In 2 o 3 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1150°C, and kept for 10 hours to obtain an ITO ceramic target.

[0042] (2) The quartz glass substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and cleane...

Embodiment 2

[0052] (1) Preparation of Ba by solid phase sintering method 0.3 Sr 0.7 TiO 3 Target and ITO target

[0053] Press Ba with electronic balance 0.3 Sr 0.7 TiO 3 The stoichiometric ratio of the corresponding elements weighs BaCO with a purity of 99%. 3 , SrCO 3 and TiO 2 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1450 ° C, and kept for 10 hours to obtain Ba 0.3 Sr 0.7 TiO 3 target;

[0054] Press Sn with electronic balance 0.03 In 0.97 O, the stoichiometric ratio of the corresponding elements Weigh SnO with a purity of 99.99% 2 and In 2 o 3 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1150°C, and kept for 10 hours to obtain an ITO ceramic target.

[0055] (2) The quartz glass substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and clea...

Embodiment 3

[0064] (1) Preparation of Ba by solid phase sintering method 0.7 Sr 0.3 TiO 3 Target and ITO target

[0065] Press Ba with electronic balance 0.7 Sr 0.3 TiO 3 The stoichiometric ratio of the corresponding elements weighs BaCO with a purity of 99%. 3 , SrCO 3 and TiO 2 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1450 ° C, and kept for 10 hours to obtain Ba 0.7 Sr 0.3 TiO 3 target;

[0066] Press Sn with electronic balance 0.03 In 0.97 O, the stoichiometric ratio of the corresponding elements Weigh SnO with a purity of 99.99% 2 and In 2 o 3 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1150°C, and kept for 10 hours to obtain an ITO ceramic target.

[0067] (2) The quartz glass substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com