Winding type permanent-magnet slip clutch and application thereof

A clutch and permanent magnet rotor technology, applied in the field of clutches, can solve the problems of eliminating braking torque, increasing actuators, cumbersome actuators, etc., and achieves the effects of large starting torque, simple control and excellent speed regulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

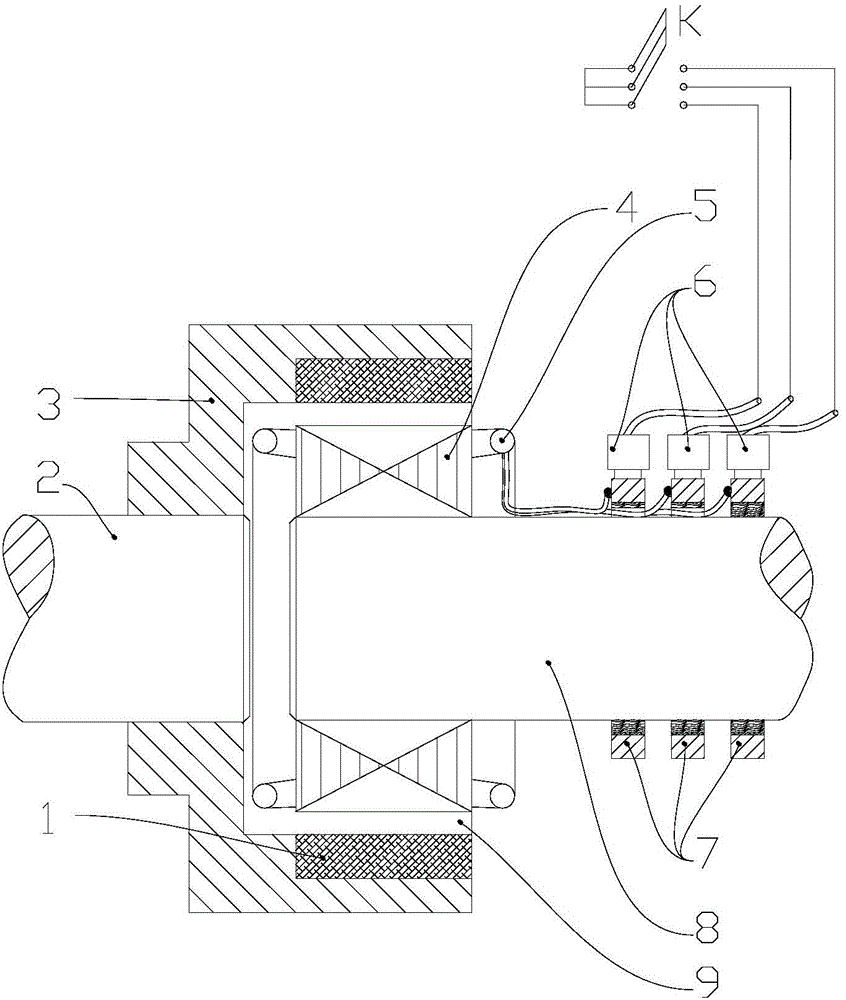

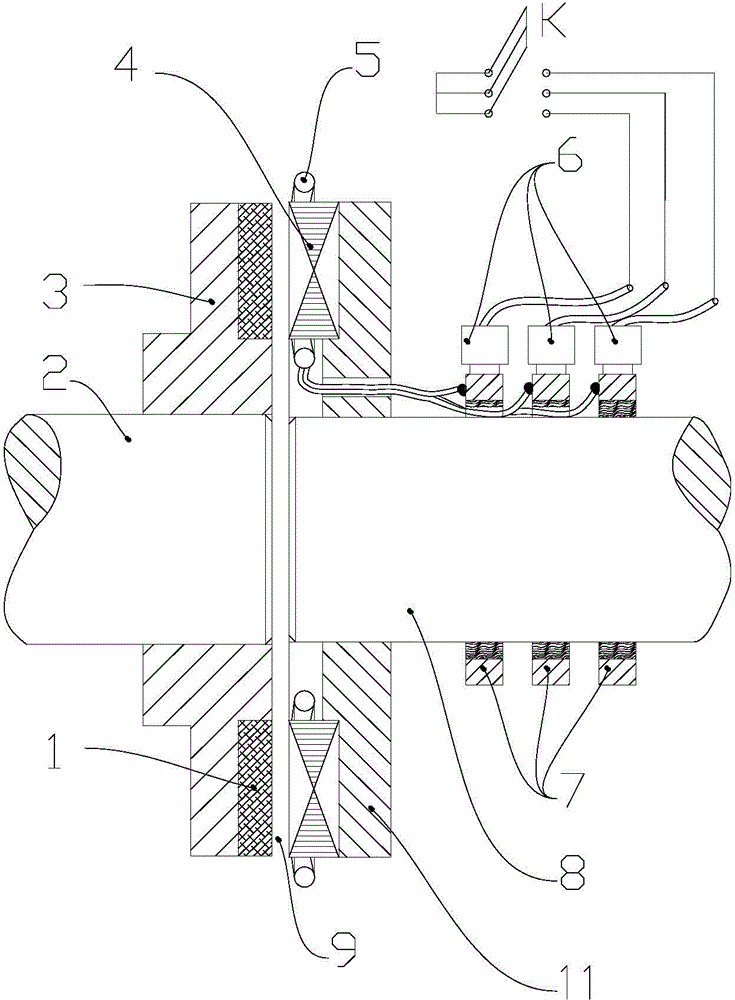

[0025] Embodiment one: figure 1 Shown is a most basic winding type permanent magnet slip clutch structure, the winding rotor and the permanent magnet rotor are coaxially arranged vertically, the permanent magnet rotor is installed on the first rotating shaft 2, the winding rotor is installed on the second rotating shaft 8, and the outer winding rotor The diameter is smaller than the inner diameter of the permanent magnet rotor; the permanent magnet rotor includes a permanent magnet 1 and a housing 3 that fixes the permanent magnet. The housing 3 is installed on the permanent magnet rotor shaft 2 8, and the N poles and S poles of the permanent magnets are alternately even on the housing 3. distribution; there is an air gap 9 between the permanent magnet rotor and the winding rotor, and the coil winding 5 can be one phase or multiple phases that can be connected symmetrically. The embodiment is a Y-shaped connection of three-phase windings. Optimum results require a series of me...

Embodiment 2

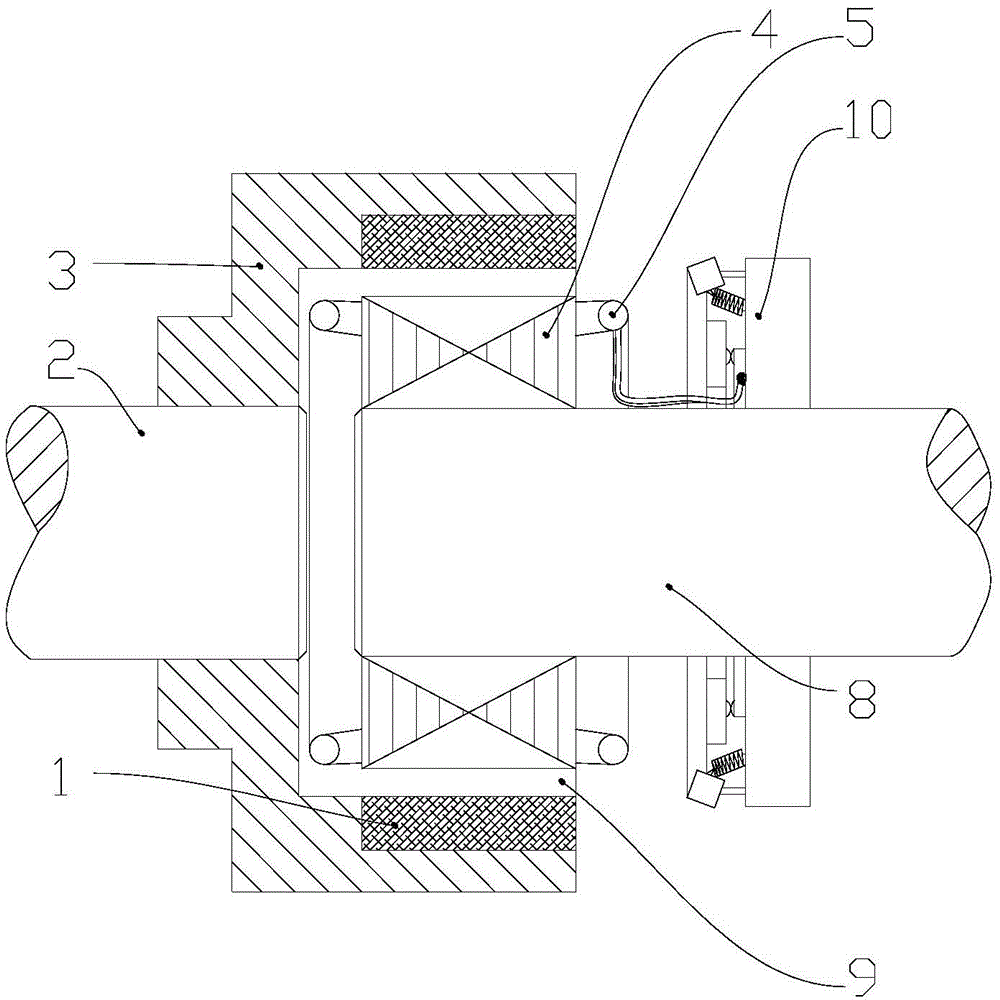

[0030] Embodiment two: in embodiment one, increase and set centrifugal switch 10, as figure 2 , the overspeed protection function can be realized. When the actual rotational speed exceeds the rotational speed set by the centrifugal switch 10, the counterweight of the centrifugal switch 10 deflects due to the centrifugal force, and the contact switch disconnects the coil winding 5, and the clutch is separated, realizing The function of the protection system; of course, it is also possible to set the speed sensor to give an overspeed signal, and then disconnect the electrical switch K to realize the overspeed protection function.

Embodiment 3

[0031] Embodiment 3: In Embodiment 1, the external switch K adopts an overcurrent protection switch. When the load increases, the current of the coil winding 5 of the winding rotor rises. When the current rises beyond the limit value, that is, the system is overloaded. The external switch trips, and the clutch Separation, automatic protection system function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com