Island-in-sea fiber, combined filament yarn and textile product

A technology of sea-island fiber and mixed fiber yarn, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve the problems of uncontrollable nanofiber configuration, suppression of nanofiber existence limit, partial shedding of island components, etc. Achieve excellent water absorption function, excellent wiping performance, and eliminate the effect of slippery feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

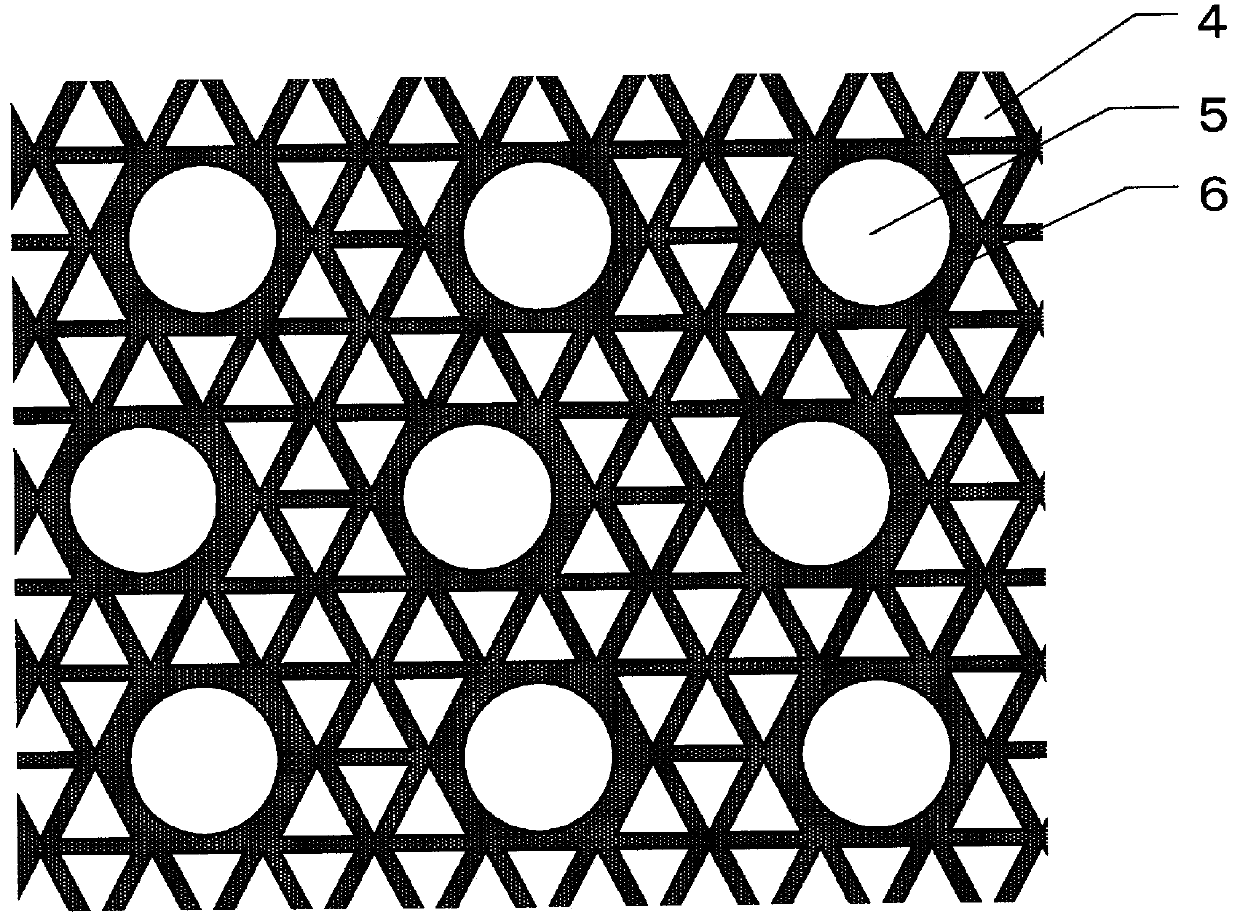

[0147] Polyethylene terephthalate (PET1 melt viscosity: 160 Pa·s) as the island component and PET (copolymerized PET1 melt viscosity: 95Pa·s) were melted at 290°C, and then measured so that they flow into the assembly Figure 6 The spin pack of the composite die of the present invention is shown, exiting the composite polymer stream from the discharge orifice. In addition, in the distribution plate directly above the discharge plate, as the island component of each discharge hole, a total of 790 distribution holes are perforated in each discharge hole, and the distribution hole 25-(a) (hole diameter: φ0.20mm ) is 720 holes, 25-(c) (aperture diameter: φ0.65mm) is 70 holes, and the arrangement pattern of the holes is Figure 7 (a) Arrangement. exist Figure 6 The annular groove for the sea component shown in 29 in (d) used the annular groove which perforated the distribution hole every 1 degree in the circumferential direction.

[0148] In addition, the length of the dischar...

Embodiment 2~4

[0160] Except for changing the composite ratio of the sea / island components to 30 / 70 (Example 2), 50 / 50 (Example 3), and 70 / 30 (Example 4), all implementations were carried out as in Example 1. The evaluation results of these sea-island fibers are shown in Table 1. Similar to Example 1, they are excellent in spinning properties and post-processing properties, and there is no partial deviation in the number of island components A or island components B in the cross section of the mixed fiber yarn. place. About water absorption and color development, it was excellent similarly to Example 1. In Example 4, compared with Example 1, although slight detachment of ultrafine fibers was confirmed, it was a problem (judgment of detachment: ◯). In addition, the stain removal rates evaluated by the same method as in Example 1 were all 80% or more, and it was confirmed that the mixed fiber yarn of the present invention has good wiping performance. The results are shown in Table 1.

Embodiment 5

[0162] Using the distribution plate used in Example 1, the sea / island composite ratio was 80 / 20 for spinning at a total output of 12.5 g / min, and the obtained undrawn fiber was drawn at a draw ratio of 3.5 times. Stretch, except that, all implement according to embodiment 1. In addition, in Example 5, although the total discharge amount was reduced, it had the same spinning property as that of Example 1. This is considered to be an effect that the island components are equally and regularly arranged.

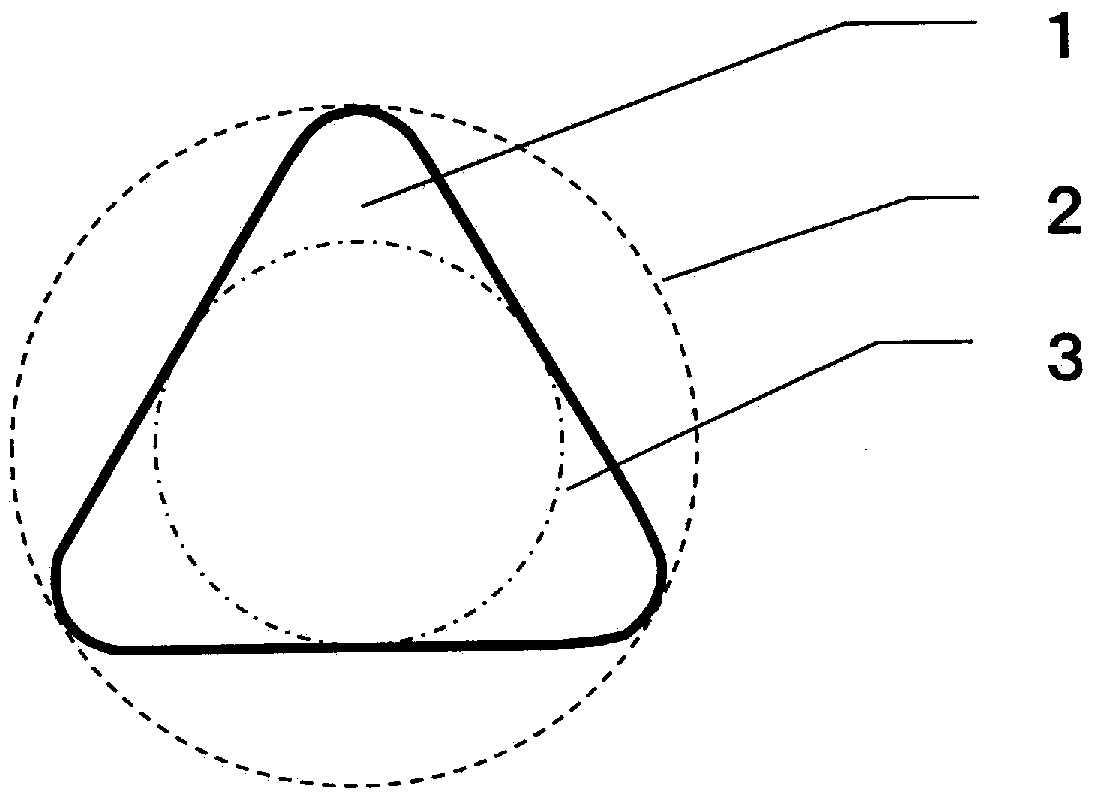

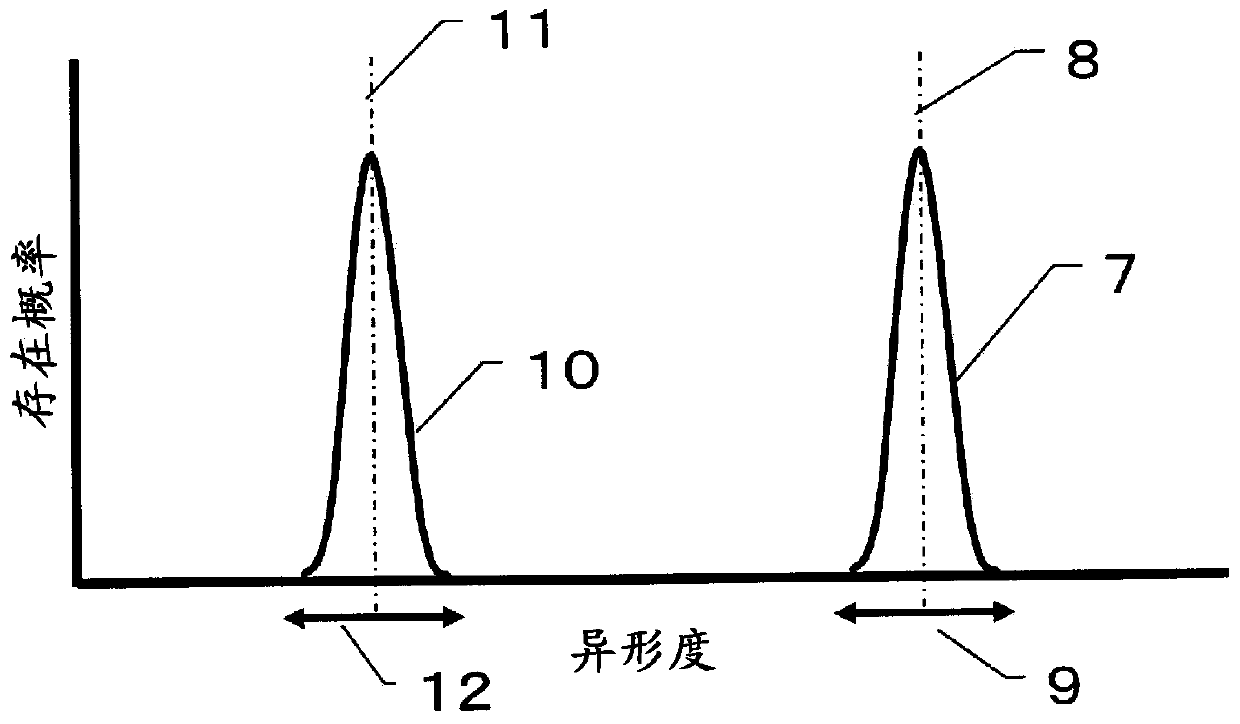

[0163] Although the cross-section of the sea-island fiber obtained in Example 5 had an extremely narrow diameter of 180 nm, the island component had a triangular cross-section (degree of irregularity 2.0), and the deviation of the degree of irregularity was also 3.0%, which was small. Since the diameter of the island component A was significantly reduced compared with Example 1, it is considered that a small amount of nanofibers that were affected during sea removal fell off, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com