Materials for controlling the epitaxial growth of photoactive layers in photovoltaic devices

A device and photosensitive layer technology, applied in the field of organic solar cells, can solve the problems of high cost, difficult production, and stability of amorphous silicon devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

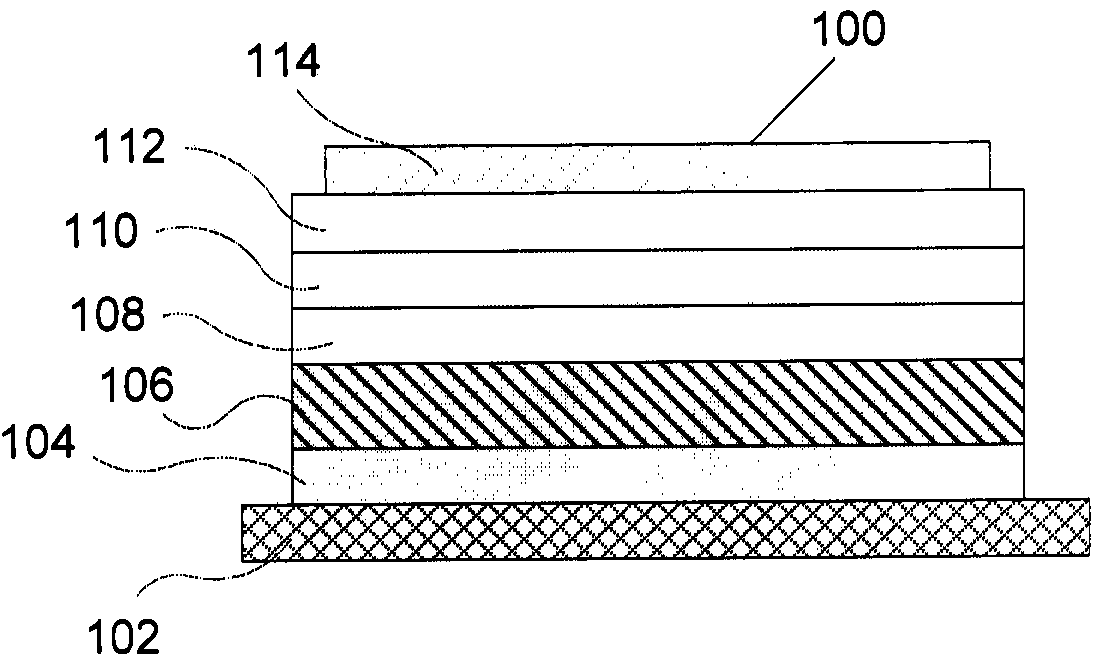

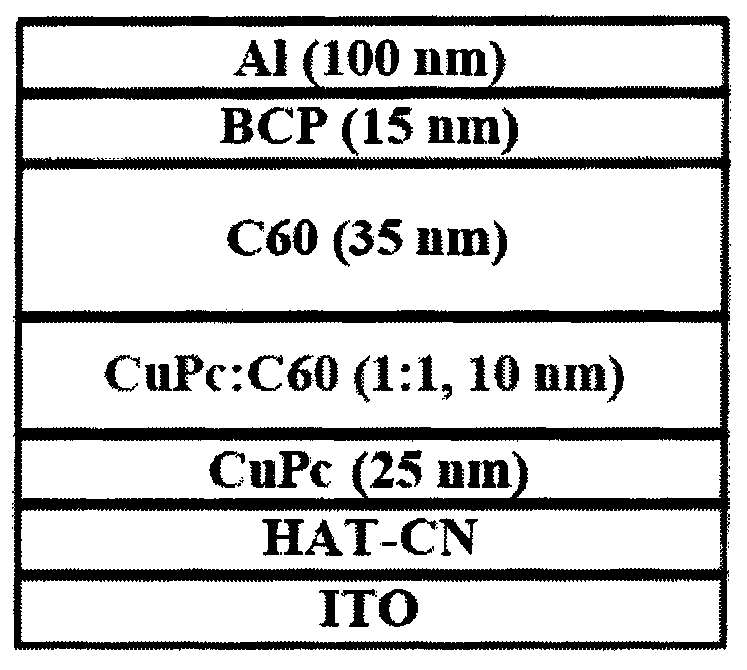

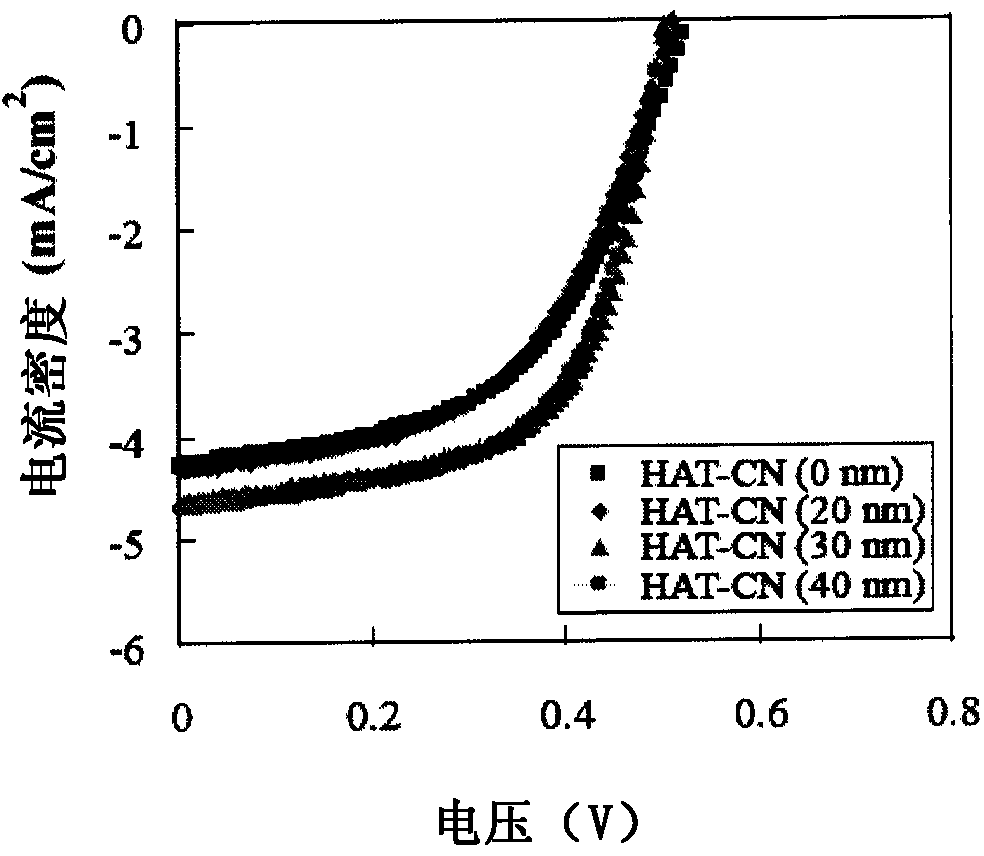

[0100] Two OPVs were fabricated as described above, one with and one without HAT-CN buffer layer. Figure 9 The dark current density (JD)-voltage and photocurrent density (JPH)-voltage characteristics of the corresponding OPVs are shown. Using the HAT-CN buffer layer increases the OPV dark current density at V>0, while the JD at V2 Enhanced to 4.6±0.05mA / cm 2 , but it is more significant to increase ff from 50%±2% to 62%±1%. Using the HAT-CN as a modeling buffer increased the PCE from 1.1%±0.1% to 1.4%±0.1% due to the increase in Jsc and ff without any significant change in Voc.

[0101] The detailed data of the HAT-CN modified OPVs are summarized in Table I. The fill factor (ff) is generally determined by the combination of series resistance and parallel resistance of the OPV. From the slope of the forward-biased JPH-V characteristic, it is evident that the decrease in series resistance is responsible for the increase in ff. Specifically, the areal series resistance calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com