CARBON DIOXIDE RECOVERY SYSTEM AND OPERATING METHOD THEREOf

A carbon dioxide, recovery system technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of reduced amine concentration and equipment performance, and achieve the effect of inhibiting the reduction of amine concentration, easy replenishment, and shortened stirring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

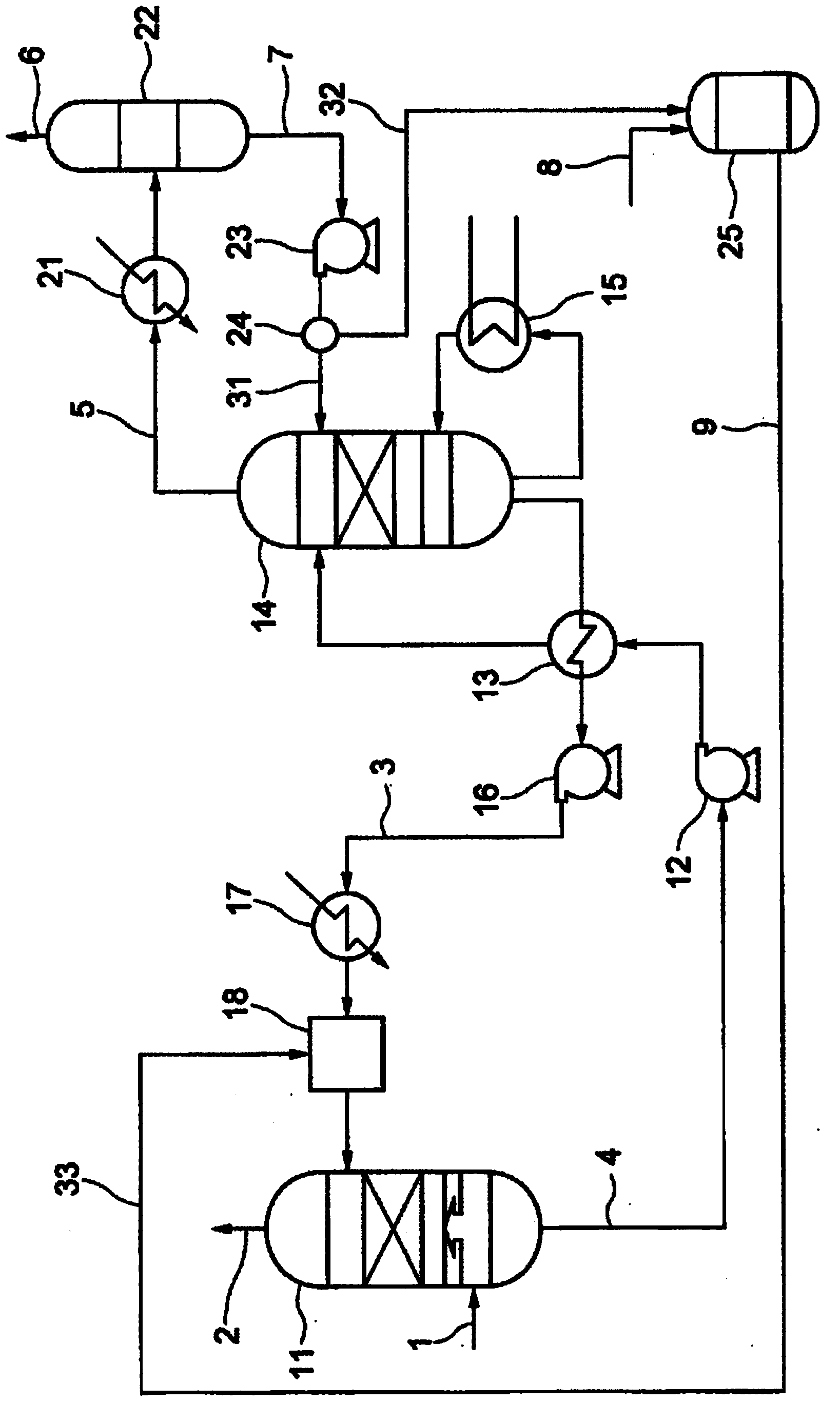

[0017] figure 1 It is a schematic diagram showing the configuration of the carbon dioxide recovery system of the first embodiment.

[0018] figure 1 The carbon dioxide recovery system of the first embodiment shown includes an absorption tower 11, a rich liquid pump (rich liquid pump) 12, a regeneration heat exchanger 13, a regeneration tower 14, a reboiler (reboiler) 15, a lean liquid pump (lean liquid pump) pump) 16, lean liquid cooler (lean liquid cooler) 17, buffer tank (buffer tank) 18, cooler 21, condenser 22, pump (pump) 23, switching valve 24 and mixer 25.

[0019] The absorption tower 11 is a carbon dioxide gas absorption tower. The absorption tower 11 makes the absorption tower inlet gas 1 containing carbon dioxide contact the absorption liquid, and makes the absorption liquid absorb carbon dioxide. Examples of the absorption tower inlet gas 1 include combustion exhaust gas generated in thermal power plants and the like. Examples of the absorbing liquid include am...

no. 2 approach

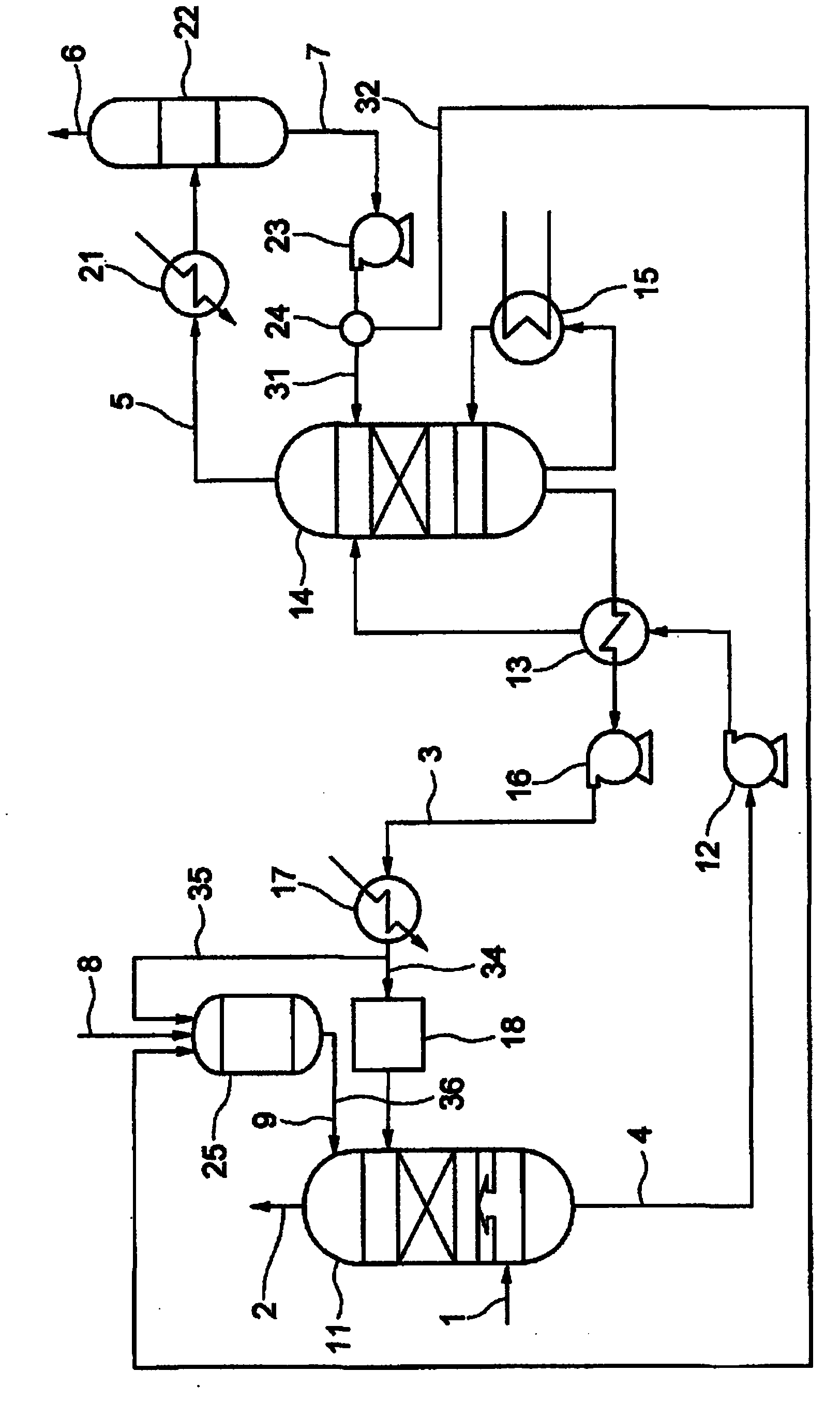

[0056] figure 2 It is a schematic diagram showing the configuration of the carbon dioxide recovery system of the second embodiment.

[0057] figure 2 The carbon dioxide recovery system of the second embodiment shown includes pipes 34 and 35 through which the lean liquid 3 discharged from the lean liquid cooler 17 circulates. The line 34 supplies the lean liquid 3 to the buffer tank 18 , and the line 35 supplies the lean liquid 3 to the mixer 25 . The mixer 25 supplies the make-up amine aqueous solution 9 directly to the absorption column 11 . The configuration other than that is the same as that of the first embodiment, and thus the description of the redundant configuration will be omitted.

[0058] The mixer 25 mixes the condensed water 7 , the make-up amine 8 from the outside, and the lean liquid 3 to generate the make-up amine aqueous solution 9 . The mixer 25 can mix the condensed water 7 , the make-up amine 8 and the lean liquid 3 at the same time. In addition, th...

Embodiment 1

[0065] Blow gas with a CO2 content rate of 99% into 100ml of water at 20°C at a flow rate of 100ml / min. After confirming that the outlet gas flow rate is equal to the inlet gas flow rate, add 10g of piperazine (piperazine) to the water. Stir with a stirrer until the piperazine dissolves. As a result, piperazine was completely dissolved in 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com