Wind wheel electrode discharging device

A discharge device and electrode technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of asymmetrical electrode life, uneven filamentary discharge, uneven discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

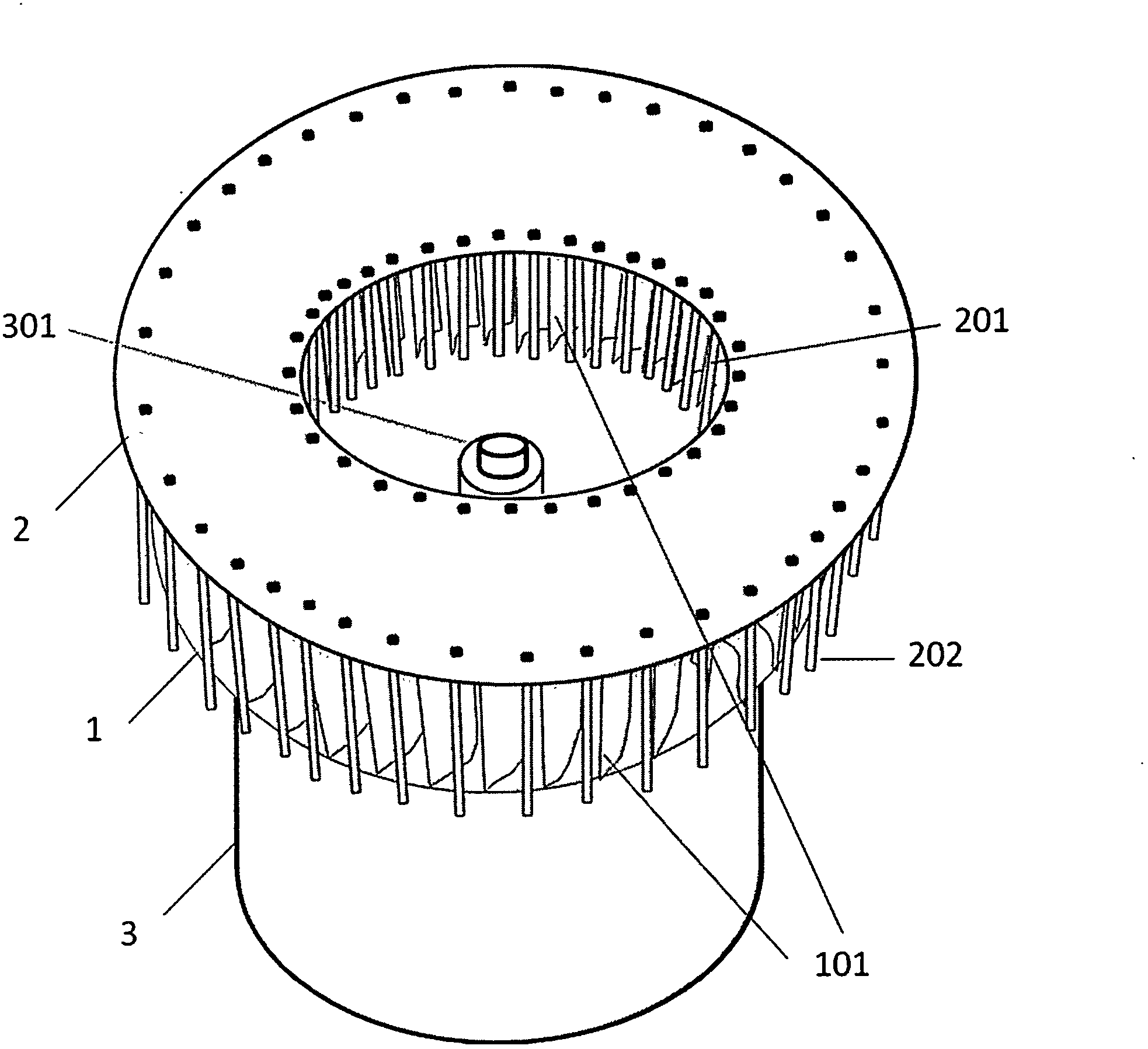

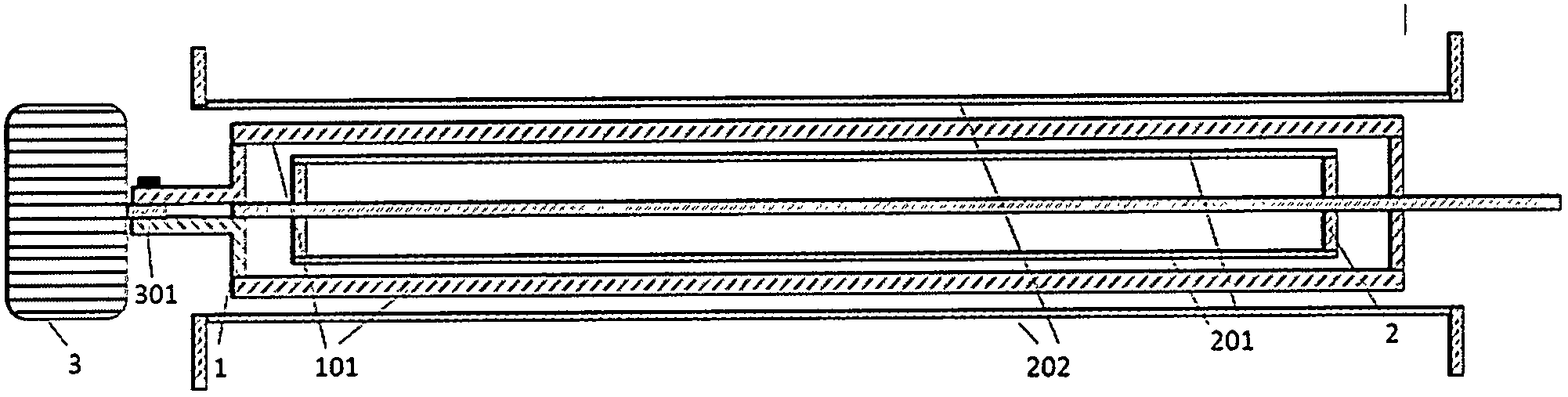

[0025] The horizontal wind wheel electrode discharge device of the specific embodiment 2 of the present invention, the schematic diagram of its axial section is as follows figure 2 shown.

[0026] The wind rotor electrode 1 is made of aluminum alloy, with an inner diameter of 69 mm, an outer diameter of 92 mm, and a length of 645 mm. The overall weight of the wind rotor is relatively heavy; the distance between adjacent blades of the wind rotor blades 101 is 15 mm, and both ends are made of insulating plastic sections Closed, the flange interface of the rotating shaft of the motor 3 and the central axis hole are left on the plastic section at both ends; the wind rotor blade is 15mm wide, the middle thickness is 1.0mm, the edge blade is 0.1mm thick, and the length is 600mm; the outer blade of the wind rotor blade is 101mm Coated with 0.5mm glass fiber cloth, the surface of the fiber cloth is coated with TiO 2 Nanoparticles; the maximum power of the motor 3 is 30W, and there a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com