Soundproof panel for automobile

A technology for panels and automobiles, which is applied to vehicle parts, synthetic resin layered products, layered products, etc., and can solve problems such as inability to effectively block noise, poor sound insulation of panels or interior panels, and increased vehicle weight and cost. Achieve the effects of easy disassembly, unchanged processing and manufacturing process, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

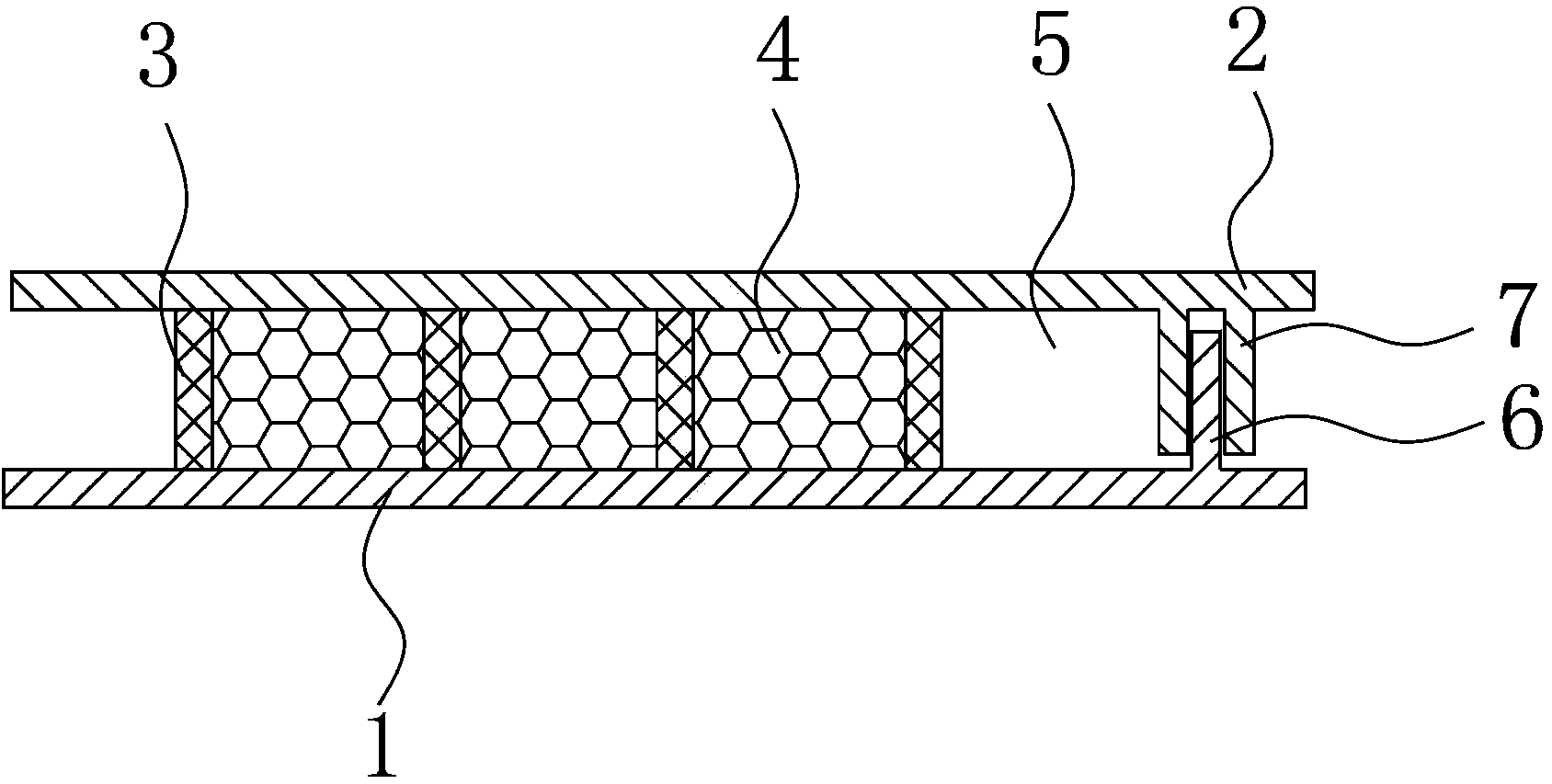

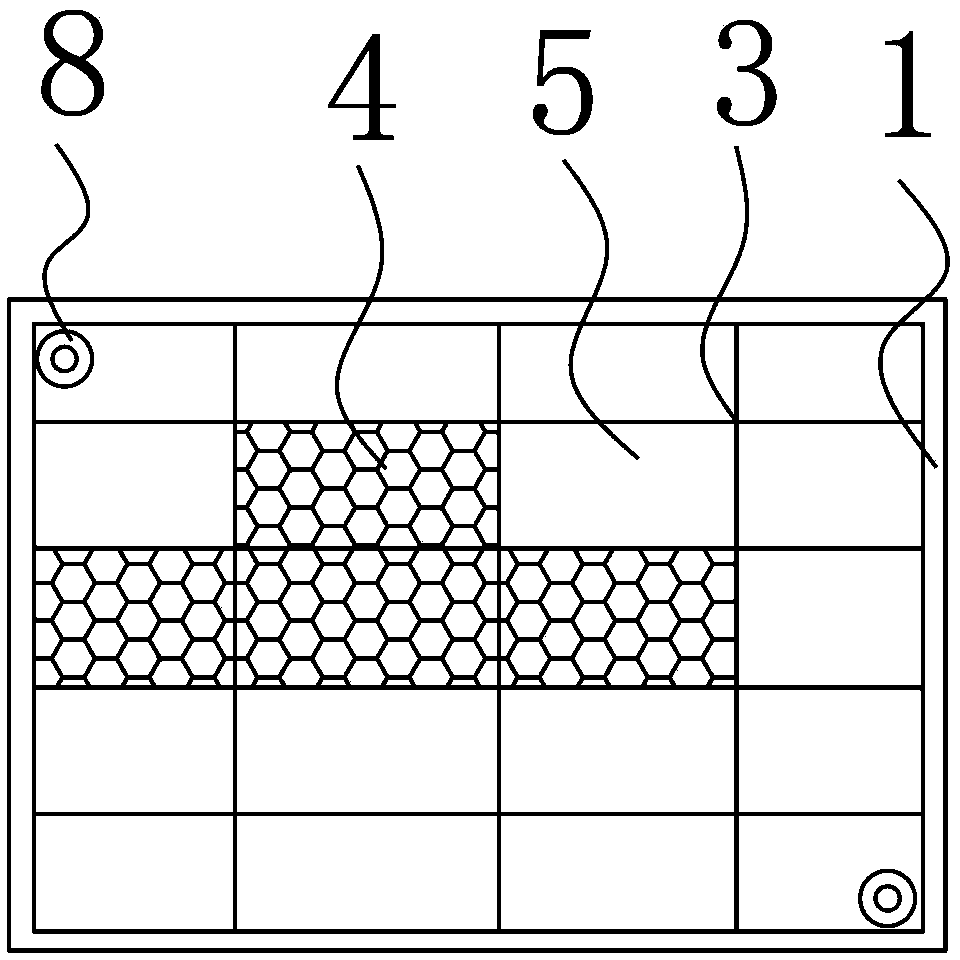

[0018] Such as figure 1 As shown, the present invention provides a car sound insulation panel, comprising a first panel 1, a second panel 2 and a sound insulation cotton 4 arranged between the first panel and the second panel, the first panel is provided with a keel 3, Wherein: the keel 3 and the first panel 1 are injection molded at one time, the keel 3 forms a lattice structure in a criss-cross pattern, and each lattice forms a sound-insulating unit 5 with a hollow structure, and the sound-insulating cotton 4 is filled in the The soundproof unit 5 also includes a connecting device 8 for connecting the first panel 1 and the second panel 2 to each other, such as figure 2 shown.

[0019] The material of the first panel 1 and the second panel 2 is epoxy resin.

[0020] The sound insulation cotton 4 is polyester fiber cotton.

[0021] The cross section of the sound insulation unit 5 is one of circular, rectangular or polygonal.

[0022] The connection means 8 are a plug 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com