A kind of lubricating grease composition and preparation method thereof

A grease composition and solid lubricant technology, applied in the field of grease, can solve the problems of reducing the lubricating effect, failure of the angle adjuster baking paint, etc., and achieve the effects of excellent extreme pressure performance, low operating torque at low temperature, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of lubricating grease composition, comprises the following steps:

[0027] mixing 40wt% to 50wt% of base oil, 2wt% to 10wt% of thickener and 35wt% to 40wt% of solid lubricant and performing homogenization treatment to obtain a grease composition precursor;

[0028] The grease composition precursor is mixed with 0.05wt%-0.50wt% structure stabilizer, 0.5wt%-2.0wt% metal deactivator, 2wt%-8wt% extreme pressure anti-wear agent and 0.2wt% ~2.0 wt% antioxidant was mixed to obtain a grease composition.

[0029] The present invention carries out homogenization treatment after mixing base oil, thickener and solid lubricant, and then mixes with described structural stabilizer, metal passivator, extreme pressure antiwear agent and antioxidant, and homogenization treatment makes each The components are uniformly dispersed, the solid-liquid phase is not separated, and a lubricating grease composition with a good colloidal structur...

Embodiment 1

[0062] Add 8kg of fluororesin to the base oil, the base oil includes 40kg of polyalphaolefin and 5kg of dipentaerythritol low carbonate, raise the temperature to 120°C, then add 35kg of calcium carbonate, stir for 30min, and use a colloid mill to cut the above materials circularly 2h, obtain the grease composition precursor;

[0063] Cool the grease composition precursor to 100°C, add 3kg molybdenum disulfide, 0.5kg polymethacrylate, 1.0kg N,N-disalicylidene propylenediamine, 3kg zinc dithiophosphate, 4kg molybdenum dithiophosphate and 0.5kg 2,6-di-tert-butylphenol, after stirring for 60min, take out the material from the colloid mill, grind the material twice with a three-wheel grinder, Obtain a grease composition;.

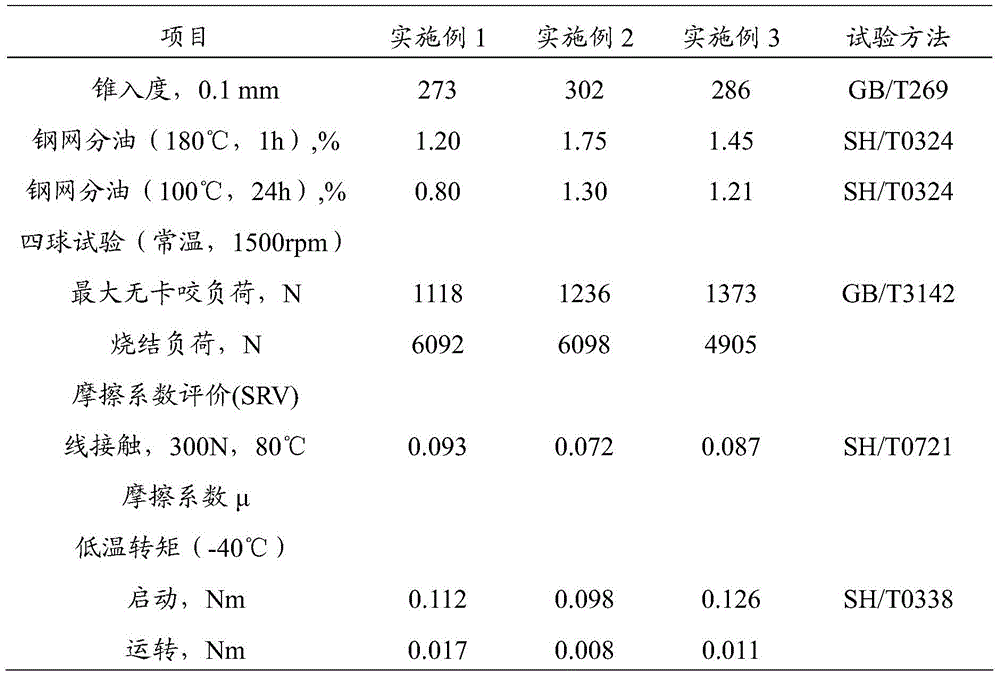

[0064] The present invention conducts a performance test on the obtained lubricating grease composition, and the test results are shown in Table 1. Table 1 shows the performance test results of the lubricating grease composition obtained in Examples 1-3 of the ...

Embodiment 2

[0066] Add 3kg of bentonite to the base oil, the base oil includes 30kg of polyalphaolefin and 20kg of hydrogenated base oil, raise the temperature to 160°C, add 40kg of melamine cyanurate, stir for 30min, and use a colloid mill to circulate and shear the above materials for 3h to obtain Grease composition precursors;

[0067] Cool the grease composition precursor to 80°C, add 0.5kg glycerin, 1.0kg N-N di-n-butylaminomethylene benzotriazole, 2kg dithiocarbamate, 3 kg of molybdenum dithiocarbamate and 0.5 kg of alkyl diphenylamine were stirred for 60 minutes, then the material was taken out from the colloid mill, and the material was ground 3 times with a three-wheel grinder to obtain a grease composition;

[0068] The present invention conducts a performance test on the obtained lubricating grease composition, and the test results are shown in Table 1. Table 1 shows the performance test results of the lubricating grease composition obtained in Examples 1-3 of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com