Extremely low concentration coal mine gas combustion device and method

A coal mine gas and combustion device technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of high failure rate of internal combustion engine power generation technology, poor economy of thermal storage oxidation technology, and large impact of gas concentration fluctuations, etc., and achieve simple structure , easy maintenance and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

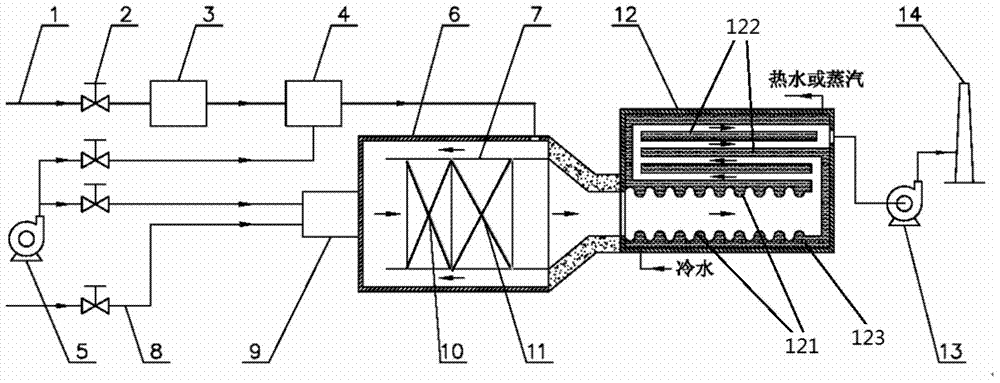

[0022] figure 1It is an embodiment of the present invention. The extremely low-concentration coal mine gas burning device of the present invention includes a gas extraction pipeline 1, a safety conveying device 3, a concentration control device 4, a blower 5, a gas burning device body 6, a waste heat boiler 12, a boiler exhaust fan 13 and a chimney 14 , the gas extraction pipeline 1 communicates with the concentration control device 4 through the safety delivery device 3, the blower 5 communicates with the concentration control device 4 through the air delivery pipeline I, and the coal mine gas exhaustion through the gas extraction pipeline 1 and the safety delivery device 3 is connected with the The air from the blower 5 passes into the concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com