Integrated modeling method for hypersonic flight vehicle engine body and internal contraction air inlet channel

A modeling method and hypersonic technology, applied in the fields of instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as inability to actually design, complex modeling method parameters, and design methods remaining in basic configuration research, etc. To achieve the effect of convenient evaluation and simple modeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

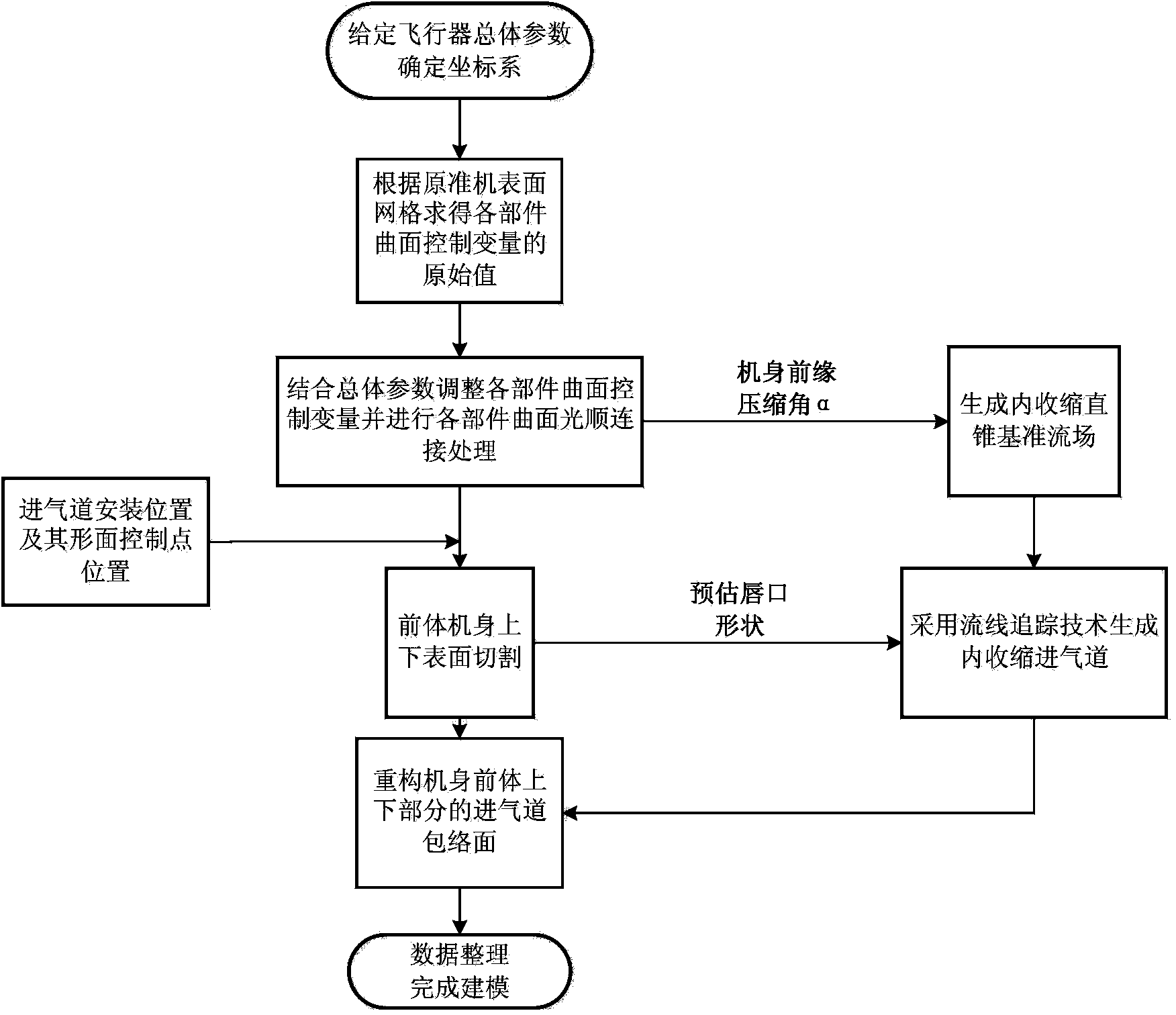

[0042] The flowchart of the overall modeling method of the present invention is as figure 1 shown.

[0043] Given the overall design index, determine the overall coordinate system:

[0044] The overall design parameters need to be given, including the length of the front body of the fuselage, the length of the rear body, the maximum width of the fuselage, the maximum thickness of the fuselage, the wing area, the aspect ratio, the tip ratio, the leading edge sweep angle and the inlet Control parameters. The coordinate system is selected as the rectangular coordinate system, the direction of the fuselage axis is the x direction, the wingspan direction is the y direction, and the z direction is the height direction of the aircraft. Determine the expression of the rectangular coordinate system

[0045] Solve for the control parameters of each block surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com