Organic light-emitting device, manufacturing method and display panel

A technology of organic light-emitting devices and manufacturing methods, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, and electric solid-state devices. and other issues to achieve high resolution and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

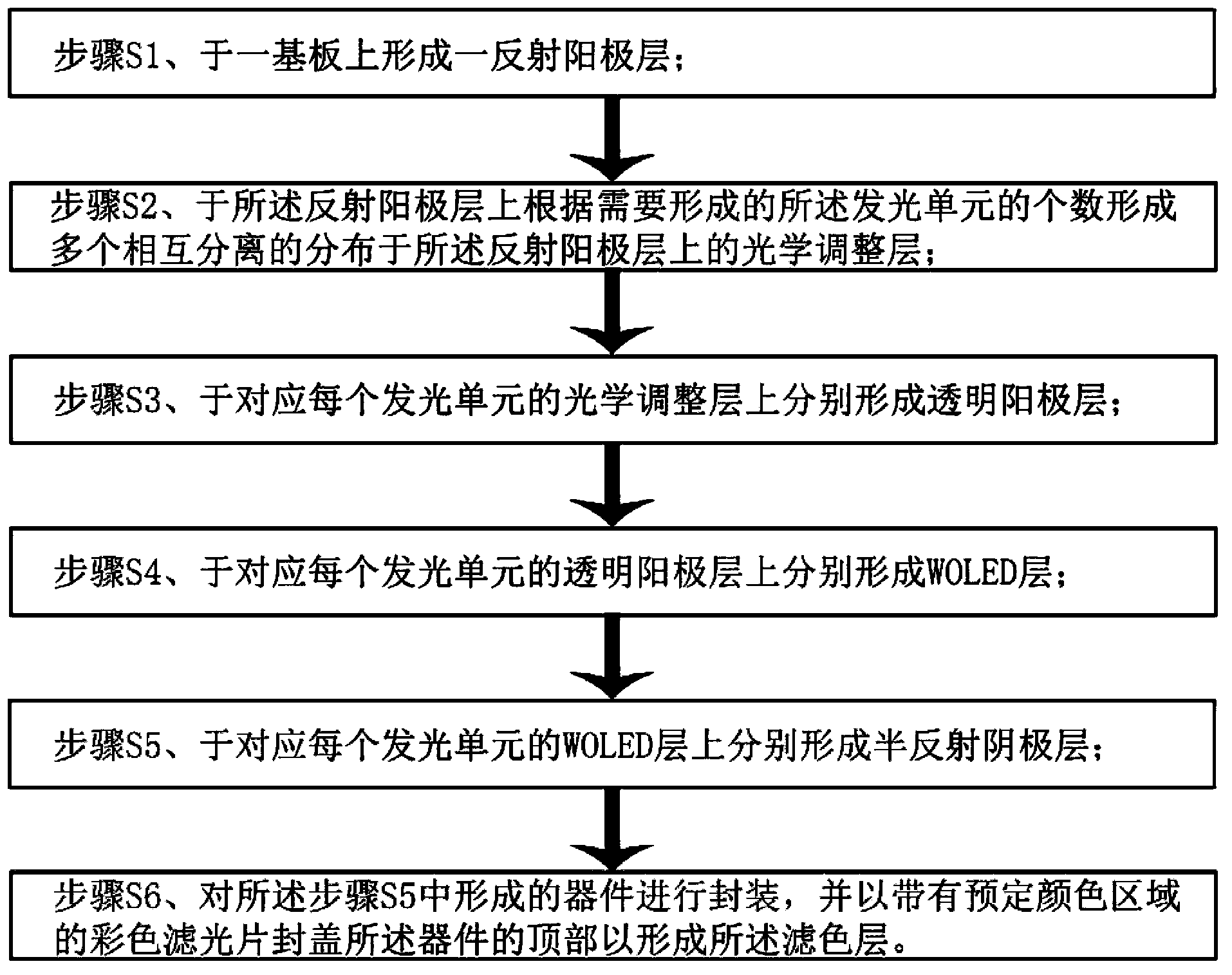

[0035] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

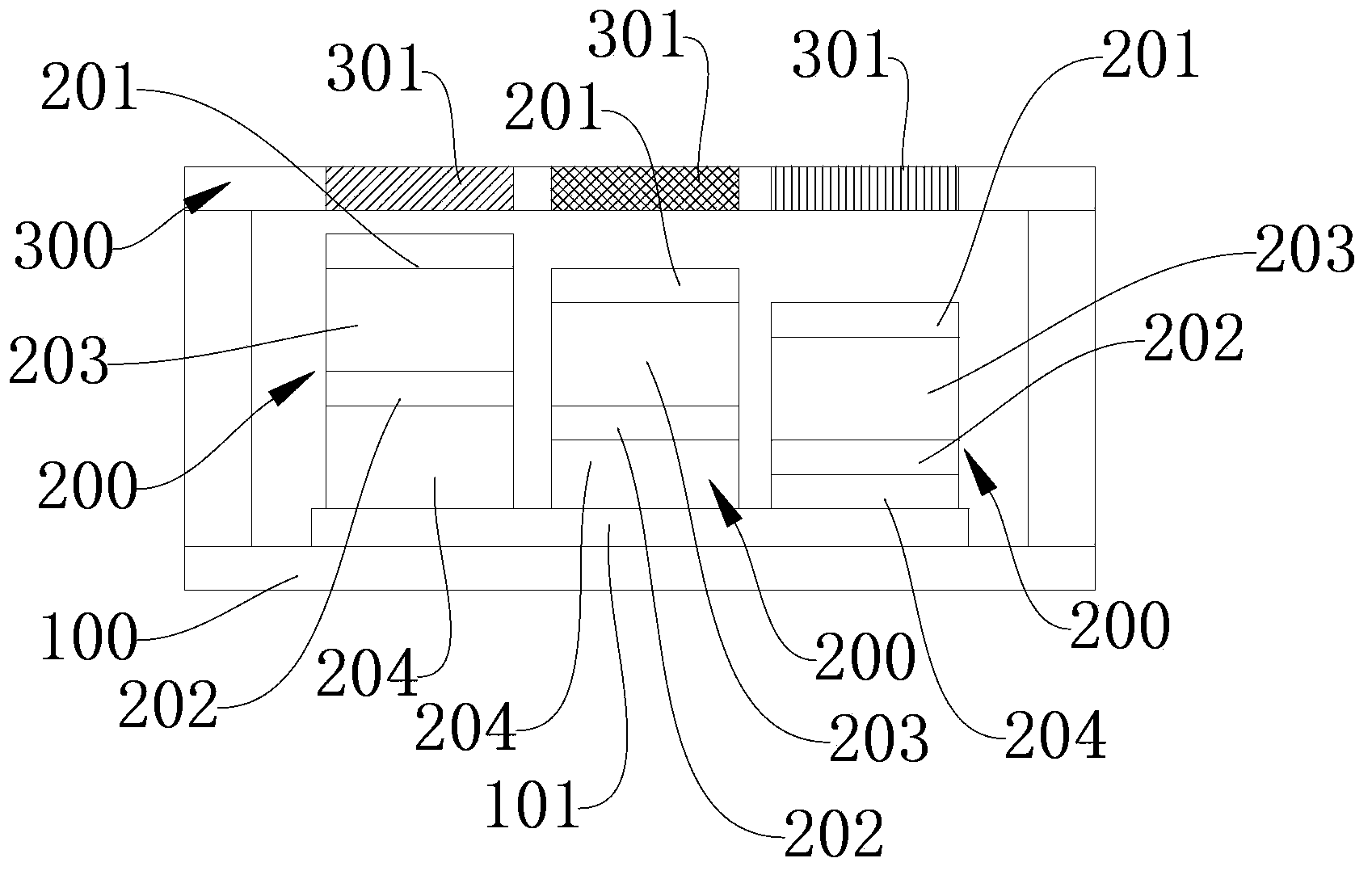

[0036] The technical solution of the present invention includes an organic light-emitting device, such as figure 1 As shown, there are a plurality of light-emitting units 200 formed on a substrate 100 and isolated from each other, each light-emitting unit 200 includes a semi-reflective cathode 201, a transparent anode 202 and sandwiched between the semi-reflective cathode 201 and the transparent anode 202 the WOLED layer 203;

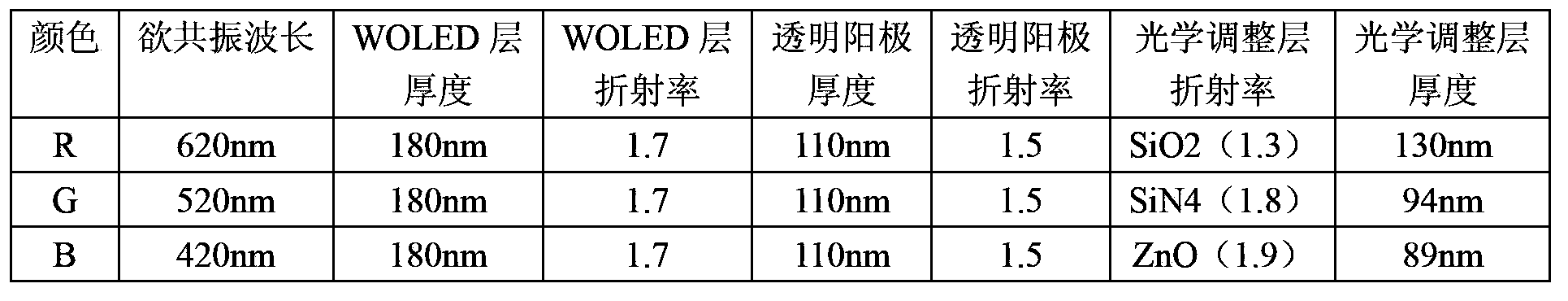

[0037] The substrate 100 is provided with a reflective anode 101 shared by a plurality of light-emitting units 200 to reflect light upward, and a respective light-emitting unit 200 is provided between the transparent anode 202 of each light-emitting unit 200 and the common reflective anode 101 . an independent optical adjustment layer 204 for adjusting the wavelength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com