Vibration movement device for main shaft of numerical control electrochemical machining machine tool

A technology of electrolytic processing machine tools and motion devices, which is applied in the direction of electric processing equipment, electrochemical processing equipment, accessory devices, etc., can solve the problems of not being too large, small driving force, and impact force, etc., to reduce equipment costs and structure Simple, improve discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

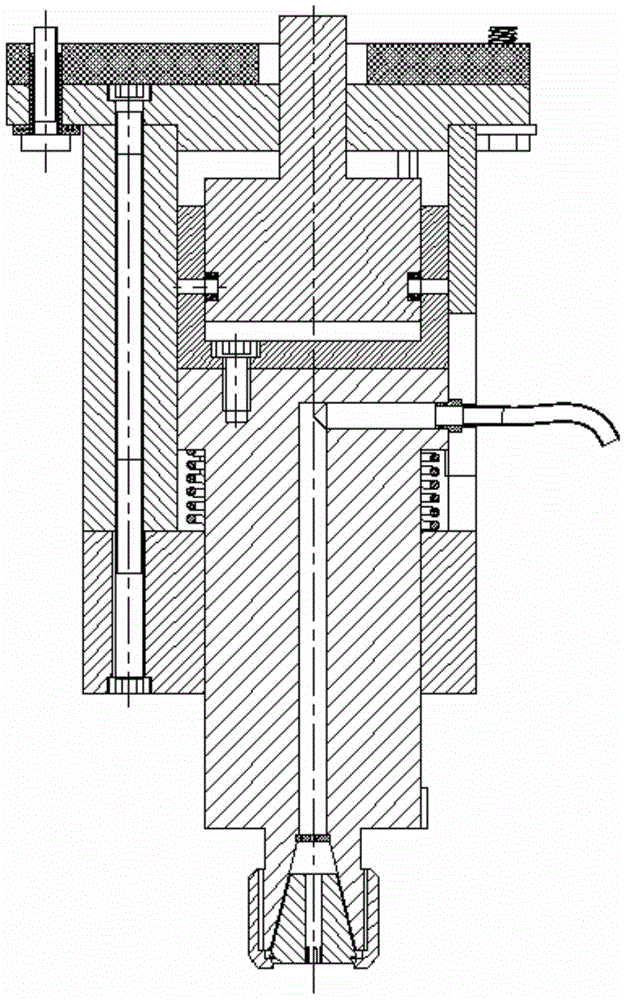

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

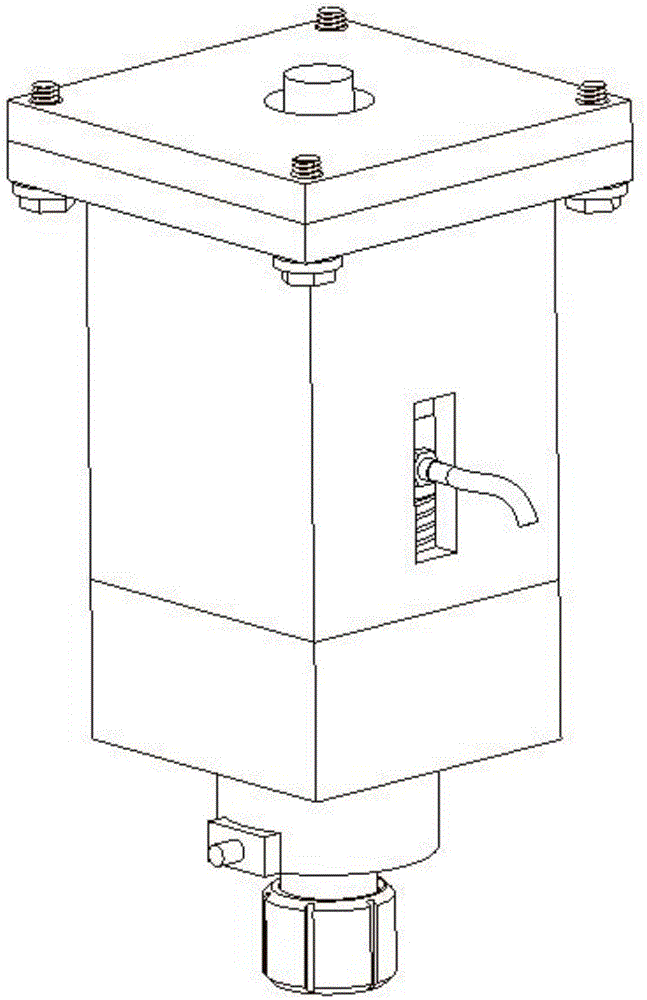

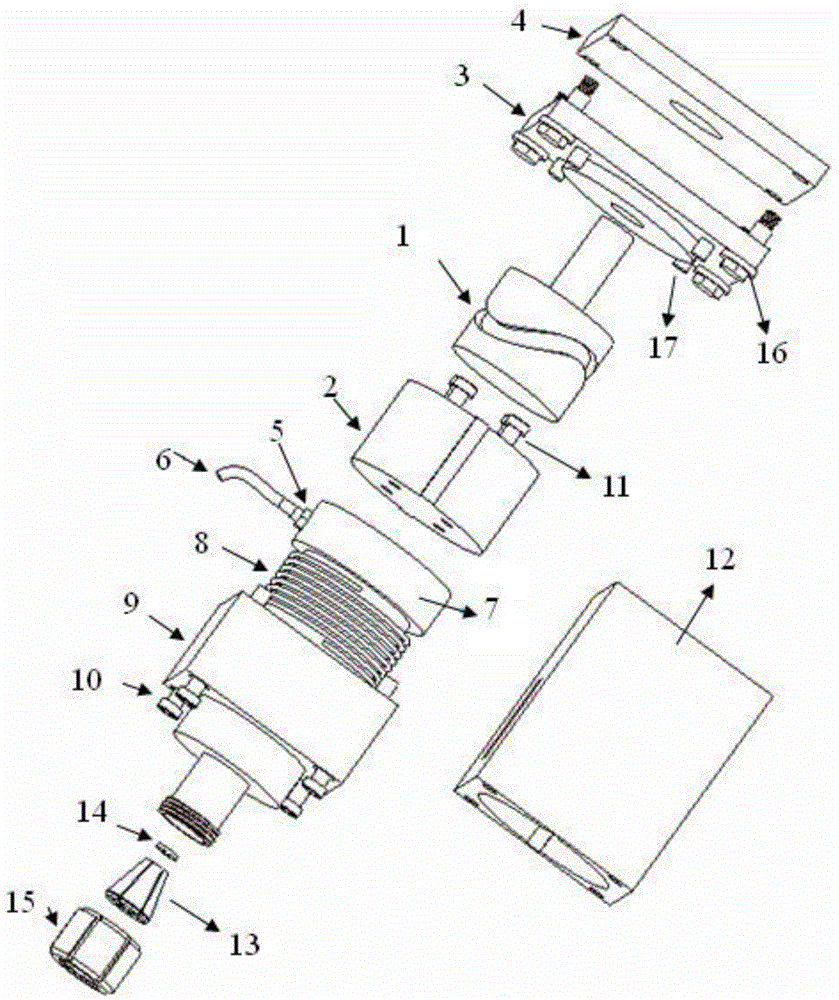

[0031] As a preferred embodiment, the structure of the vibrating motion device for the spindle of the CNC electrolytic machining machine tool of the present invention is as follows: Figure 1-3 As shown, it includes space cam 1, cam guide sleeve 2, vibration shaft 7, guide sleeve 9, guide housing 12, end cover 3, insulating plate 4, quick connector 5, electrolyte inlet pipe 6, support spring 8, sealing ring 14 , Spring collet 13, lock nut 15, insulating bolt 16 and so on.

[0032] The structure of space cam 1 is as follows Figure 4 As shown, its upper part is the torque input shaft 1-1, and the guide groove 1-2 of the space cam 1 is a symmetrical sine wave groove;

[0033] The structure of the cam guide sleeve 2 is as follows: Figure 5 As shown, its interior is hollow, and its diameter matches the outer diameter of the space cam 1. There are two sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com