Manufacturing method of electronic product shell

A manufacturing method and technology of electronic products, applied in the direction of household components, household appliances, other household appliances, etc., can solve problems such as singleness, and achieve the effect of saving process, increasing diversification, and increasing a sense of unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Example: such as Figure 1 to Figure 3 Described, a kind of manufacturing method of electronic product shell, comprises the following steps:

[0018] Step 1: Select the compound of PC and 20%-30% CF as conductive plastic particles, select the compound of PPS and GF as non-conductive plastic particles, bake the conductive plastic particles and non-conductive plastic particles, and the conductive plastic particles The baking temperature is 120 degrees, and the baking time is 4H. The baking temperature of non-conductive plastic particles is 80 degrees, and the baking time is 4H;

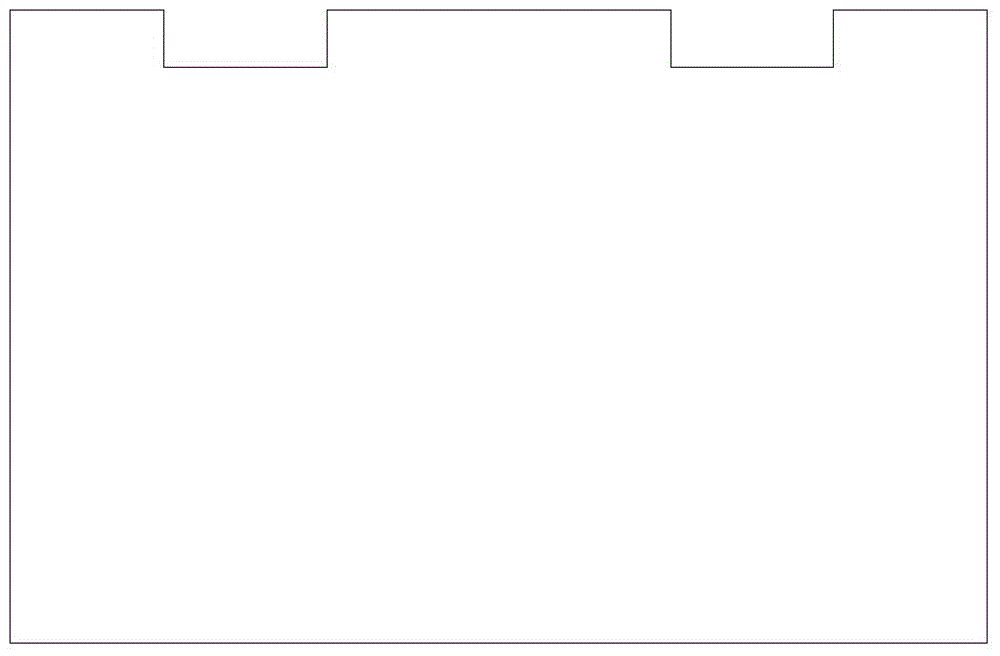

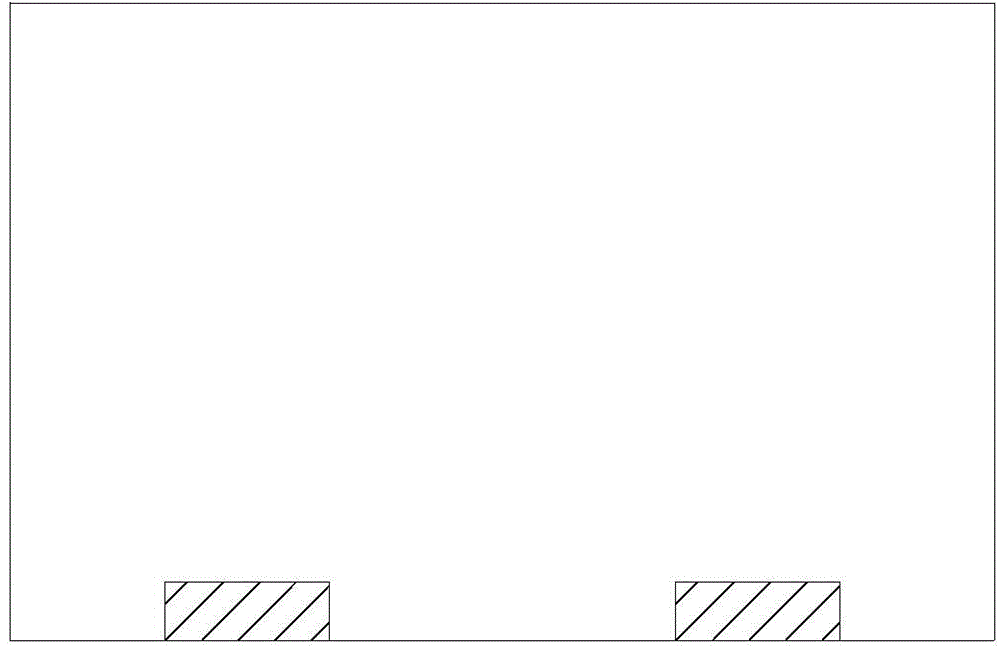

[0019] Step 2: The main body of the conductive plastic particles is formed in the first mold A. The injection molding conditions are: mold temperature 70°C ~ 95°C, barrel temperature 270°C ~ 315°C, injection pressure 130~150Mpa, injection time 3~4 seconds, cooling time 40 seconds, back pressure 13bar;

[0020] Step 3: Use the two-color injection molding motorized template to rotate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com