Integrated molding and manufacturing method of megawatt wind power cabin cover by pouring

A technology for a wind turbine cabin and a manufacturing method, which is applied to other household appliances, household appliances, household components, etc., can solve problems such as the impact on the health of operators, the large impact on the production quality of products, and the long occupied time of molds, and improve the anti-fatigue performance. , The effect of stable product quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

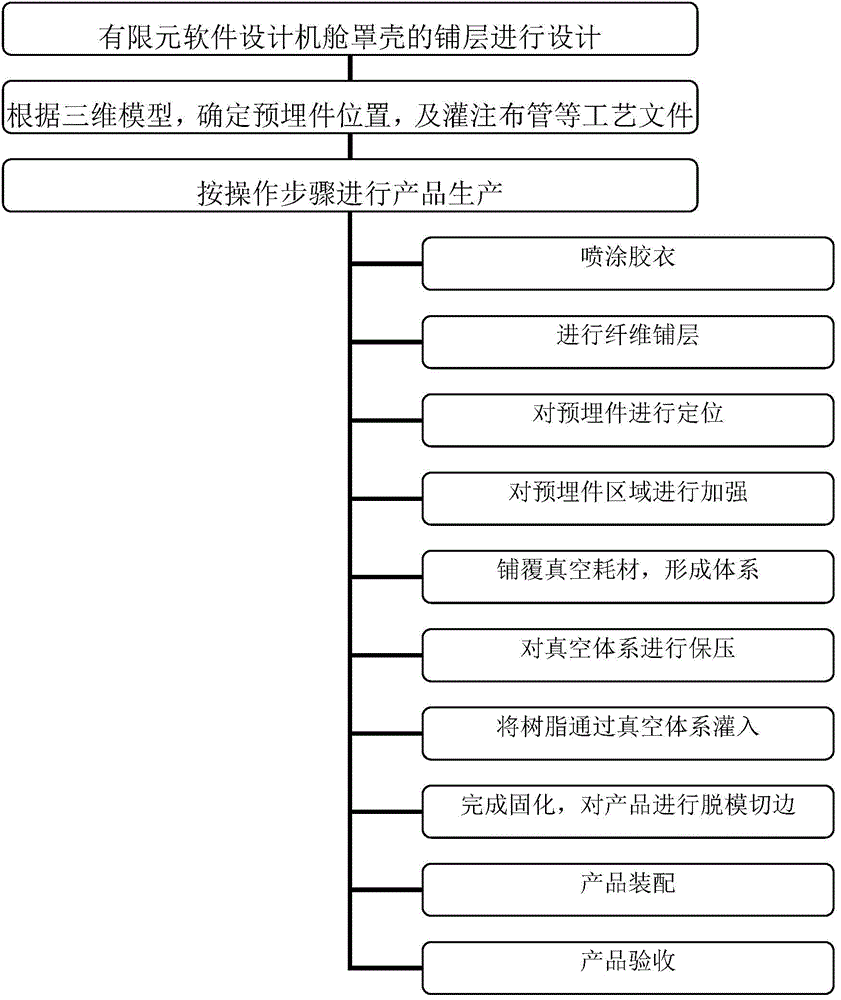

[0032] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings. Preparation method of the present invention comprises the steps:

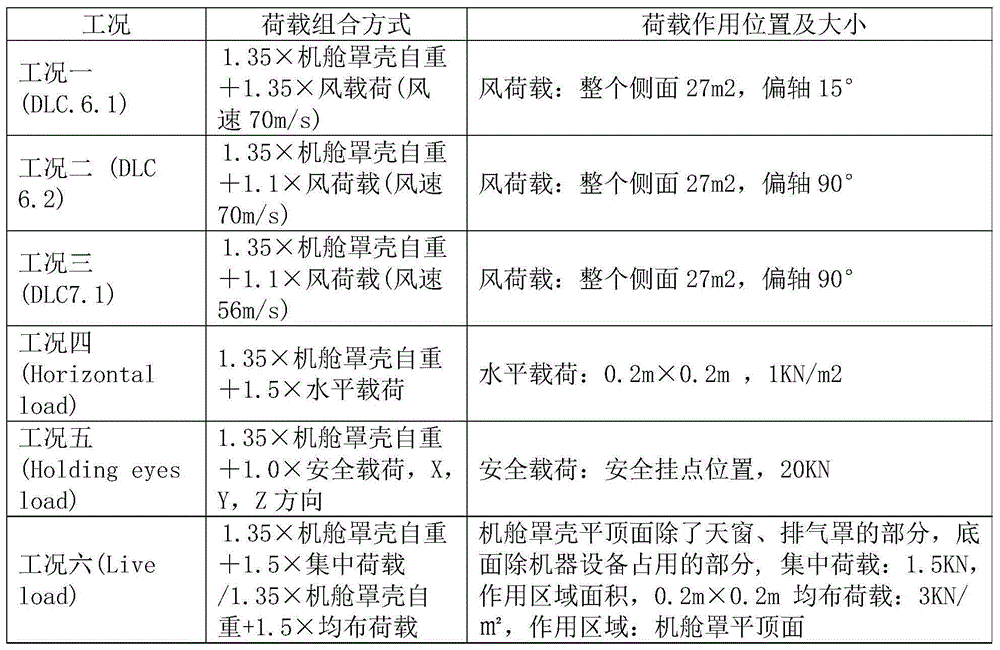

[0033] Step 1. Through the finite element software, design the lay-up structure of the cabin shell according to the GL2010 specification; it needs to be designed according to the six working conditions listed in the GL2010 specification (as shown in the table below):

[0034]

[0035] Step 2. Use 3D software to design the position of the embedded parts, the perfusion piping diagram, and the position of the vacuum consumables. For example, according to the three-dimensional model, measure the position and size of the parts reflected in the mold in the three-dimensional model, and pre-embed nuts on the mold, and fix the position of the embedded parts through the nuts. For pouring and distributing pipes, arrange the glue inlet and air outlet according to the shape of the mold to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com