Alkaline earth aluminum silicate glass substrate and components thereof

A technology of aluminosilicate glass and glass substrate, applied in the field of alkaline earth aluminosilicate glass substrate and its composition, can solve the problems of low clarification gas temperature, low effectiveness of glass bubbles, toxicity, etc., and improve the yield of production line Large, production cost reduction, the effect of lowering the melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

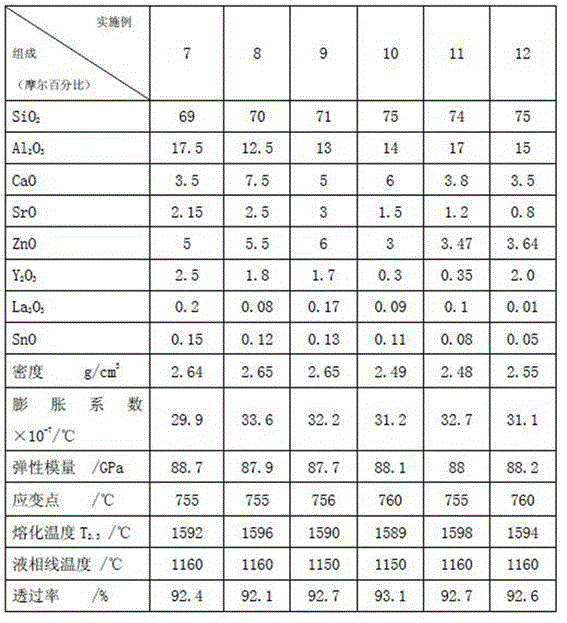

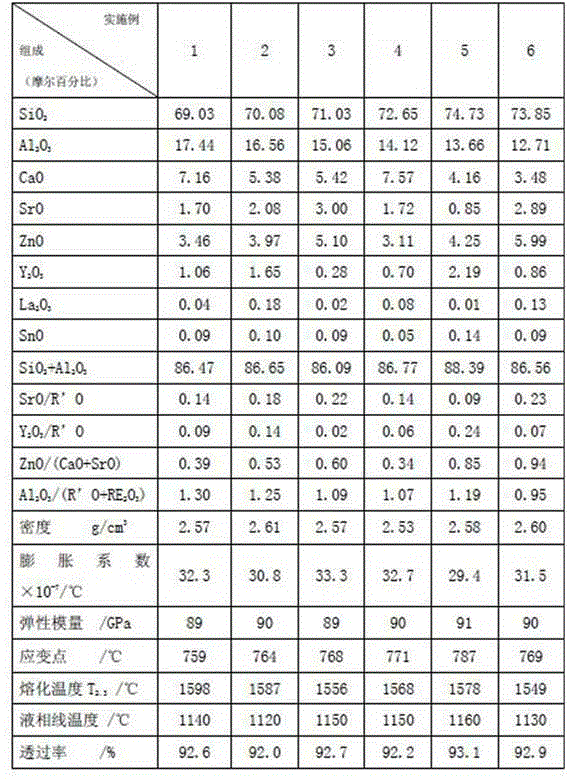

[0019] The key to the alkaline earth aluminosilicate glass substrate and its composition is: the molar percentage meter of each component in the original glass substrate includes:

[0020] SiO 2 69~75%,

[0021] Al 2 O 3 12.5~17.5%,

[0022] CaO 3.5~7.5%,

[0023] SrO 0.8~3%,

[0024] ZnO 3~6%,

[0025] Y 2 O 3 0.3~2.5%,

[0026] La 2 O 3 0.01~0.2%.

[0027] Among the components: SiO 2 +Al 2 O 3 > 86%.

[0028] Among the components: SrO / R’O <0.25, where R’O=CaO+SrO+ZnO.

[0029] Among the components: Y 2 O 3 / R’O <0.25.

[0030] Among the components: ZnO / (CaO+SrO)> 0.3.

[0031] Among the components: Al 2 O 3 / (R’O+RE 2 O 3 )> 0.95.

[0032] The glass substrate uses SnO as a clarifying agent, and its content is 0.05 to 0.15% in terms of mole percentage.

[0033] Among the components: SiO 2 The preferred mole percentage is 70~74%, Al 2 O 3 The preferred mole percentage of is 13-17%.

[0034] Among the components: the preferred mole percentage of ZnO is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com