Formula of anti-corrosion concrete used for filling pile and preparation method of anti-corrosion concrete

A concrete and anti-corrosion technology, applied in the field of civil engineering, can solve the problems of reducing anti-corrosion performance, inaccurate mixing methods, affecting concrete performance, etc., to achieve the effect of reducing engineering costs, ensuring work performance, and ensuring anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

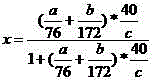

Image

Examples

Embodiment

[0046] In a bored pile project along the coast, groundwater has a strong corrosion effect on concrete and the steel bars in the concrete. The concrete strength grade of the concrete design pile body is C30, and the concrete slump is 200mm. The design process of the concrete mix ratio is as follows:

[0047] 1. Select qualified concrete raw materials, whose specifications are as follows:

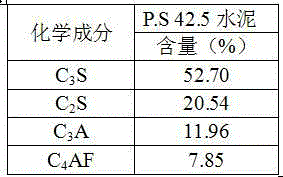

[0048] Cement: P.S42.5 Ordinary Portland Cement,

[0049]Medium sand: fineness modulus 3.2, apparent density 2.25g / cm 3 , mud content 2.0%,

[0050] Crushed stone: particle size range 1.0-31.5mm, apparent density 2.09 g / cm 3 , mud content 3.0%,

[0051] Fly ash: Class II fly ash,

[0052] Polyacrylate: Add 0.05%-0.1% according to the cementing material (the total amount of cement and fly ash),

[0053] Sodium nitrite: add 0.2%-0.4% according to the cementing material (the total amount of cement and fly ash),

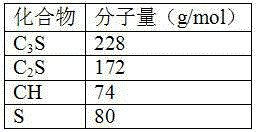

[0054] 2. Analyze the chemical composition of cement and fly ash. Its compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com