Polyurethane imide-graphene/nanometer carbon fiber blending wave-absorbing foam material and preparation method thereof

A technology of polyurethane imide and nano-carbon fiber, which is applied in the field of wave-absorbing materials, can solve the problems of complex process, increased wedges, and small application range, and achieve the effect of simple preparation process and good wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

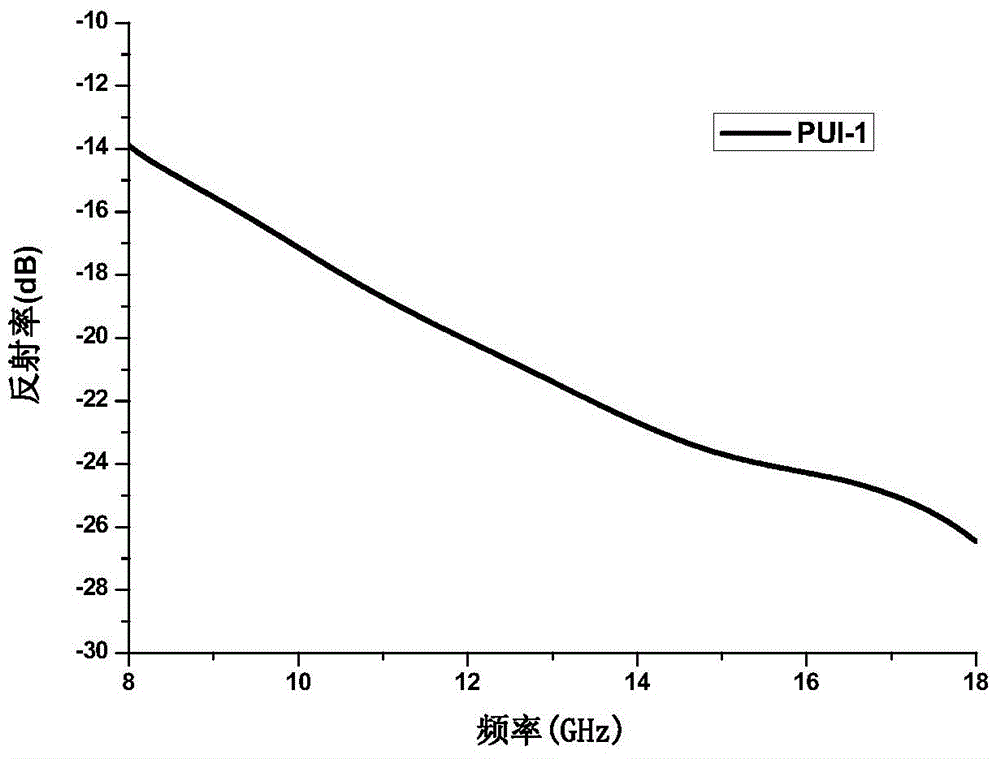

[0037] Embodiment 1, preparation polyurethane imide-graphene / nano-carbon fiber blended wave-absorbing foam material (PUI-1)

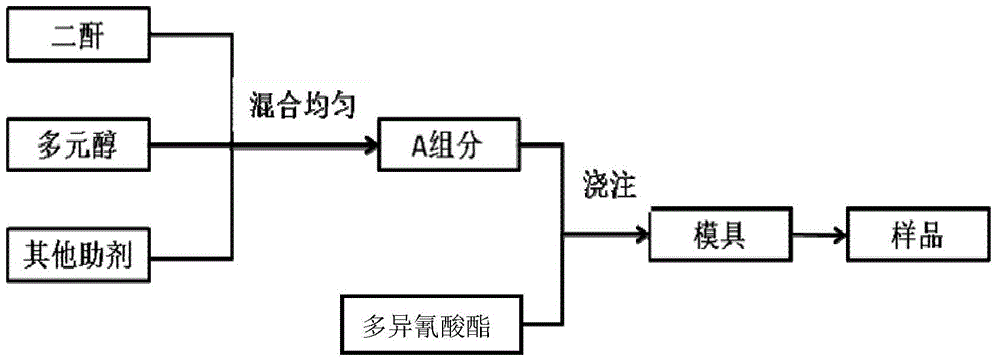

[0038] The preparation process of this embodiment is as follows figure 1 shown.

[0039] (1) Weigh 30g of 3,3,4,4-benzophenone tetraacid dianhydride in a beaker, add rosin polyester polyol (FC-300, hydroxyl value 400mgKOH / g, viscosity (25 ℃) is 6100mPa.s) 55g, polycarbonate diol (molecular weight is 2000) 15g, silicone oil 3.0g, tributylamine 1.5g, the ethylene glycol solution 1.0g of 33wt% triethylenediamine, stannous octoate 0.7 g, H 2 1.0g of O, 0.3g of graphene and 0.5g of carbon nanofibers (150-200nm in diameter and 10-30μm in length) were stirred thoroughly to make them evenly mixed to prepare Component A for later use.

[0040] (2) Component A is mixed with 67g of polyphenyl polymethylene polyisocyanate (PM-200) and fully stirred, and injected into the mold cavity after mixing evenly, and foamed at 25°C for 40 minutes; after the foam is stable...

Embodiment 2

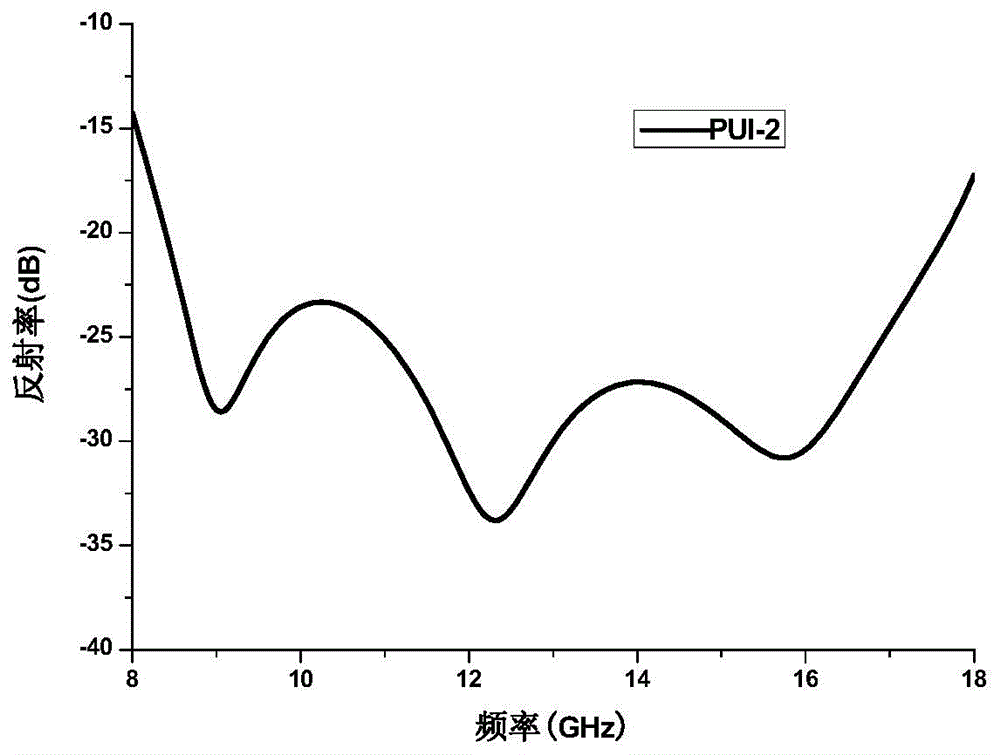

[0046] Embodiment 2, preparation polyurethane imide-graphene / nano-carbon fiber blended wave-absorbing foam material (PUI-2)

[0047] The preparation process of this embodiment is as follows figure 1 shown.

[0048] (1) Weigh 3,3,4,4-benzophenone tetraacid dianhydride 30g in a beaker, add rosin polyester polyol (FC-300, hydroxyl value 400mgKOH / g, viscosity ( 25 ℃) is 6100mPa.s) 35g, polycarbonate diol (molecular weight is 2000) 35g, silicone oil 3.0g, tributylamine 1.5g, the ethylene glycol solution 1.0g of 33wt% triethylenediamine, stannous octoate 0.7g, H 2 1.0 g of O, 0.3 g of graphene and 1.0 g of carbon nanofibers (150-200 nm in diameter and 10-30 μm in length) were stirred thoroughly to make them evenly mixed to prepare component A for later use.

[0049] (2) Component A is mixed with 54g of polyphenyl polymethylene polyisocyanate (PM-200) and stirred thoroughly, and injected into the mold cavity after mixing evenly, and foamed at 25°C for 40 minutes; after the foam is...

Embodiment 3

[0055] Embodiment 3, preparation polyurethane imide-graphene / nano-carbon fiber blended wave-absorbing foam material (PUI-3)

[0056] The preparation process of this embodiment is as follows figure 1 shown.

[0057] (1) Weigh 3,3,4,4-benzophenone tetraacid dianhydride 30g in a beaker, add rosin polyester polyol (FC-300, hydroxyl value 400mg KOH / g, viscosity ( 25 ℃) is 6100mPa.s) 15g, polycarbonate diol (molecular weight is 2000) 55g, silicone oil 3.0g, tributylamine 1.5g, ethylene glycol solution 1.0g of 33wt% triethylenediamine, stannous octoate 0.7g, H 2 1.0g of O, 0.3g of graphene and 1.5g of carbon nanofibers (150-200nm in diameter and 10-30μm in length) were stirred thoroughly to make them evenly mixed to prepare Component A for later use.

[0058] (2) Mix Component A with 41 g of polyphenyl polymethylene polyisocyanate (PM-200) and stir thoroughly, inject it into the mold cavity after mixing evenly, and foam at 25°C for 40 minutes; after the foam is stable , taken out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com