Preparation method for regenerated wood plastic composite material

A composite material and regenerated wood technology, which is applied in the field of polymer material preparation, can solve the problems of great difference in toughness and wood, low rigidity, etc., and achieve the effects of alleviating the shortage of forest resources, improving compatibility and wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

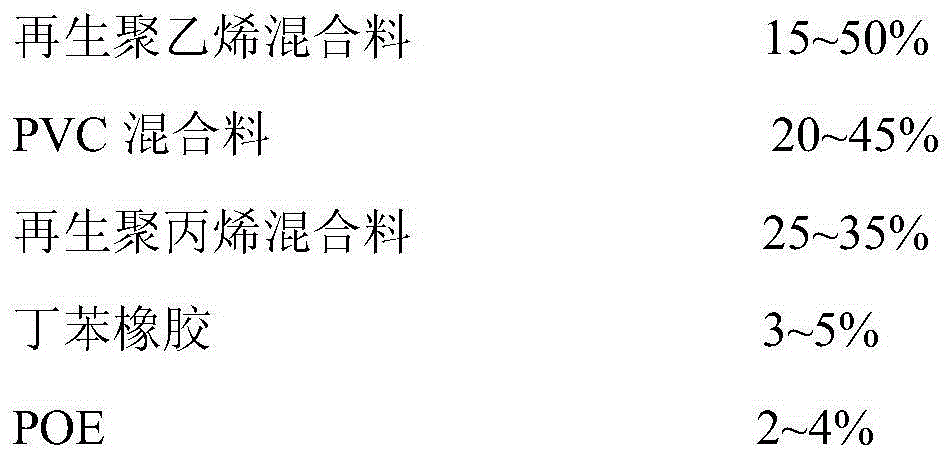

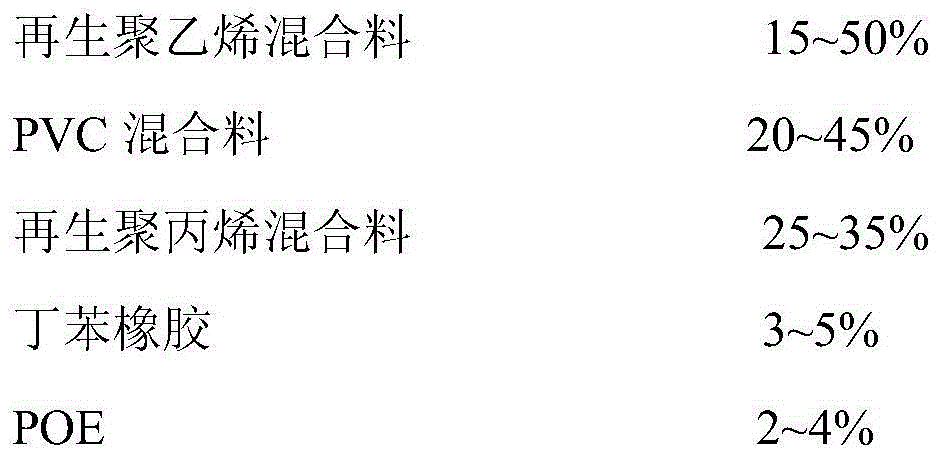

[0049] A kind of preparation method of recycled wood-plastic composite material, described preparation method is carried out according to the following steps:

[0050] Preparation of base material for recycled wood-plastic composites

[0051] A Regenerated polyethylene is a mixture of recycled high-density polyethylene and recycled low-density polyethylene, the melt flow rate is 1.5-10g / 10min, the ash content is ≤5%, and the recycled polyethylene is dried in a dryer at a drying temperature of 110 °C to obtain regenerated polyethylene with a moisture content≤3%, and the dried regenerated polyethylene and maleic anhydride grafting agent are respectively by mass percentage:

[0052] Recycled polyethylene 95-98%

[0053] Maleic anhydride grafting agent 2~5%

[0054] Mix evenly at a high speed in a high-speed mixer, the mixing time is 5-10min, and the temperature is 90-100°C to obtain a recycled polyethylene mixture for use; the maleic anhydride grafting agent is PE-g-MAH, light ...

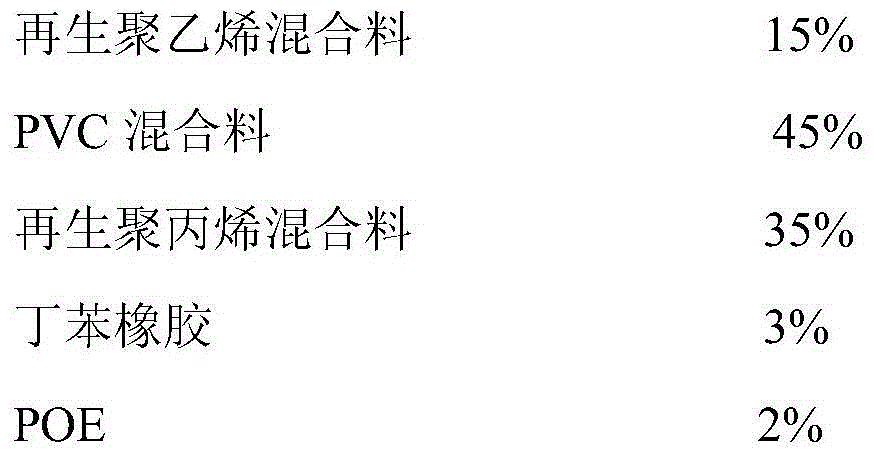

Embodiment 1

[0084] According to the above preparation method

[0085] Preparation of base material for recycled wood-plastic composites

[0086] A The melt flow rate of recycled polyethylene is 10g / 10min, and the ash content is ≤5%. Dry the recycled polyethylene in a dryer at a drying temperature of 110°C to obtain recycled polyethylene with a moisture content of ≤3%. Dry the recycled polyethylene Regenerated polyethylene and maleic anhydride grafting agent are respectively by mass percent:

[0087] Recycled Polyethylene 95%

[0088] Maleic anhydride grafting agent 5%

[0089] Mix evenly in a high-speed mixer at a high speed for 5 minutes at a temperature of 90°C to obtain a recycled polyethylene mixture for later use.

[0090] B The melt flow rate of recycled polypropylene is 1.5g / 10min, the ash content is ≤5%, the titanate coupling agent is NTC-131, and the recycled polypropylene is dried in a dryer at a drying temperature of 110°C to obtain moisture Content ≤ 3% recycled polypropyl...

Embodiment 2

[0119] According to the above preparation method

[0120] Preparation of base material for recycled wood-plastic composites

[0121]A The melt flow rate of recycled polyethylene is 1.5g / 10min, and the ash content is ≤5%. Dry the recycled polyethylene in a dryer at a drying temperature of 110°C to obtain recycled polyethylene with a moisture content of ≤3%. After drying, The regenerated polyethylene and maleic anhydride grafting agent are respectively by mass percent:

[0122] Recycled Polyethylene 98%

[0123] Maleic anhydride grafting agent 2%

[0124] Mix evenly at high speed in a high-speed mixer, the mixing time is 10min, and the temperature is 100°C to obtain a recycled polyethylene mixture, which is set aside.

[0125] B The melt flow rate of recycled polypropylene is 10g / 10min, the ash content is ≤5%, the titanate coupling agent is NTC-132, and the recycled polypropylene is dried in a dryer at a drying temperature of 110°C to obtain the moisture content ≤3% recycled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com