High-efficiency concentrated detergent liquid

A laundry liquid, high-efficiency technology, applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of no washing function, complex formula, waste of chemicals, etc., and achieve strong washing ability , moderate foam, and the effect of reducing total emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

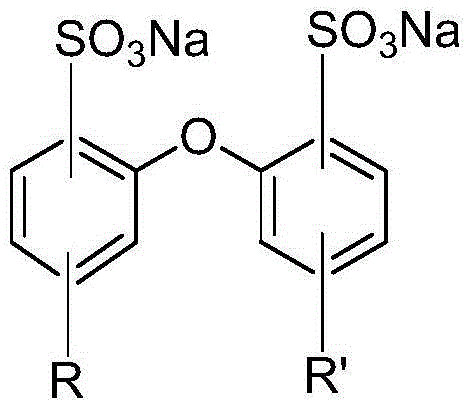

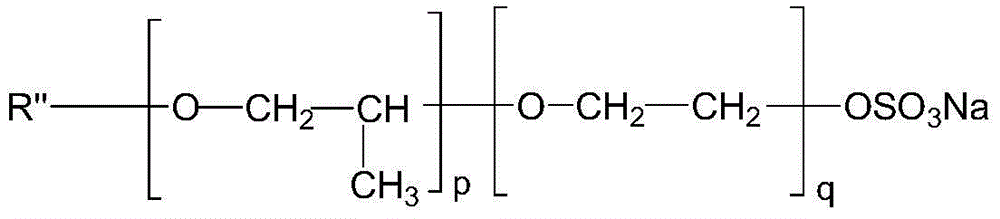

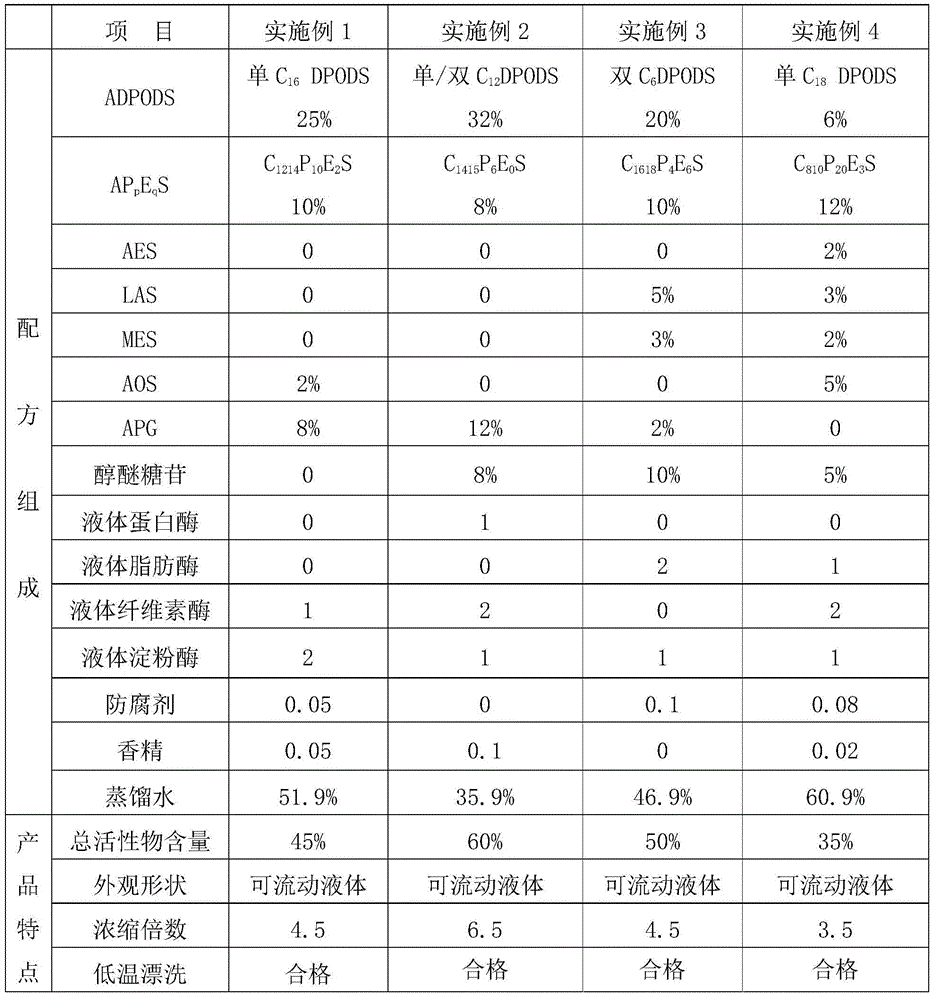

[0022] The main feature of the present invention's high-efficiency concentrated laundry detergent is to adopt alkyl diphenyl ether disulfonate (ADPODS) and alkyl alcohol polyoxypropylene polyoxyethylene ether sulfate (AP p E. q S) As the main surfactant, other commonly used anionic surfactants, such as: alkyl alcohol ether sulfate (AES), sodium alkylbenzene sulfonate (LAS), fatty acid methyl ester sulfonate (MES), a- Olefin sulfonate (AOS) is a co-surfactant, and uses alkyl glycoside nonionic surfactant to replace a large amount of fatty alcohol polyoxyethylene ether (such as: AEO 9 ), the types and amounts of additives such as enzymes, preservatives, and essences used for washing are the same as those of traditional laundry detergents, but no organic solvents, hydrotropes, and water chelating agents are added. Since preservatives and essences are common materials, in the following examples, only the types and amounts of different surfactants in the laundry detergent formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com