Environment-friendly composite laundry detergent and preparation method thereof

A laundry detergent and environmentally friendly technology, applied in the field of daily chemicals, can solve the problems of increased resource and energy consumption, difficult rinsing of foam, poor low-temperature washing performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

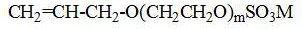

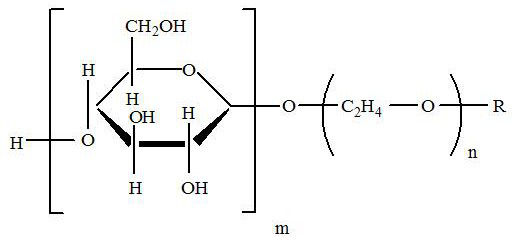

[0023] The present embodiment provides a kind of laundry liquid, according to gross mass 100%, comprise sodium acryl alcohol polyoxyethylene ether sulfate 5%; N, N-didecyl chitosan sodium sulfate 3%; Alkyl glucoside 5% 9% saponin extract; 2% lemon flavor; 0.9% sodium silicate; 1% sodium carboxymethylcellulose; 0.25% tetrasodium edetate; 74.85% deionized water.

[0024] Specific preparation steps: Add deionized water into the reaction kettle, heat it to 60°C, add saponin extract, stir until completely dissolved; then raise the temperature to 70°C, add sodium propylene alcohol polyoxyethylene ether sulfate, didecyl Chitosan sodium sulfate, alkyl glucoside, stir until completely dissolved; after cooling, add lemon essence, sodium silicate, sodium carboxymethylcellulose, tetrasodium edetate, adjust the pH value to 6-7, let it stand A high-efficiency and environment-friendly compound laundry detergent can be obtained.

Embodiment 2

[0026] The present embodiment provides a kind of laundry liquid, according to gross mass 100%, comprise propylene alcohol polyoxyethylene ether sodium sulfate 7.5%; N,N-didodecanyl chitosan sodium sulfate 5%; Alcohol ether glycoside ( n=1) 6%; saponin extract 10%; lemon essence 2.5%; sodium silicate 1%; sodium carboxymethylcellulose 1.25%; tetrasodium edetate 0.5%; deionized water 66.25%.

[0027] The preparation method is the same as in Example 1.

Embodiment 3

[0029] The present embodiment provides a kind of laundry liquid, according to 100% of total mass, comprises propylene alcohol polyoxyethylene ether sodium sulfate 10%; N, N-didecyl chitosan sodium sulfate 3%, N, N-bis Sodium Lauryl Chitosan Sulfate 6%; Alkyl Glycoside 5%, Alcohol Ether Glycoside (n=1) 5%; Saponin Extract 11%; Lemon Flavor 3%; Sodium Silicate 1.1%; Carboxymethyl Sodium cellulose 1.5%; tetrasodium edetate 0.75%; deionized water 53.65%.

[0030] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com