Aloe antibacterial yarn

A technology of yarn and aloe, which is applied in the field of aloe antibacterial yarn, can solve the problems of susceptibility to bacterial erosion, etc., achieve high market promotion value, easy to widely promote, and good antibacterial and antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

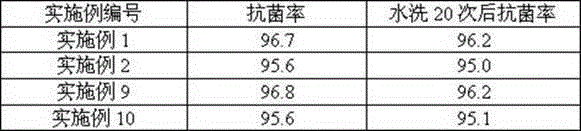

Examples

Embodiment 1

[0031] Aloe antibacterial yarn, made of regenerated cellulose, aloe extract, silver zeolite antibacterial agent through the following methods:

[0032] (1) Mix aloe extract with regenerated cellulose viscose, and wet spin to obtain aloe viscose fiber; the aloe extract accounts for 30wt% of the aloe viscose fiber in terms of dry matter.

[0033] (2) Mix silver zeolite antibacterial agent (particle size 1.0-2.0μm) with regenerated cellulose viscose, and obtain antibacterial viscose fiber by wet spinning; the added amount of silver zeolite antibacterial agent is 2.5wt of regenerated cellulose %.

[0034] (3) The aloe viscose fiber obtained in step (1) is blended with the antibacterial viscose fiber obtained in step (2).

[0035] The aloe viscose fiber accounts for 50% of the total weight of the yarn, and the antibacterial viscose fiber accounts for 50% of the total weight of the yarn.

Embodiment 2

[0037] Aloe antibacterial yarn, made of regenerated cellulose, aloe extract, silver zeolite antibacterial agent through the following methods:

[0038] (1) Mix aloe extract with regenerated cellulose viscose, and wet spin to obtain aloe viscose fiber; the aloe extract accounts for 20wt% of the aloe viscose fiber in terms of dry matter.

[0039] (2) Mix silver zeolite antibacterial agent (particle size 1.0-2.0μm) with regenerated cellulose viscose, and wet spin to obtain antibacterial viscose fiber; the added amount of silver zeolite antibacterial agent is 3wt% of regenerated cellulose .

[0040] (3) The aloe viscose fiber obtained in step (1) is blended with the antibacterial viscose fiber obtained in step (2).

[0041] The aloe viscose fiber accounts for 60% of the total weight of the yarn, and the antibacterial viscose fiber accounts for 40% of the total weight of the yarn.

Embodiment 3

[0043] Aloe antibacterial yarn, made of regenerated cellulose, aloe extract, silver zeolite antibacterial agent through the following methods:

[0044] (1) Mix aloe extract with regenerated cellulose viscose, and wet-spin to obtain aloe viscose fiber; the aloe extract accounts for 1 wt% in the aloe viscose fiber in terms of dry matter.

[0045] (2) Mix silver zeolite antibacterial agent (particle size 0.5-1.0 μm) with regenerated cellulose viscose, and wet-spin to obtain antibacterial viscose fiber; the added amount of silver zeolite antibacterial agent is 5wt% of regenerated cellulose .

[0046] (3) The aloe viscose fiber obtained in step (1) is blended with the antibacterial viscose fiber obtained in step (2).

[0047] The aloe viscose fiber accounts for 99% of the total weight of the yarn, and the antibacterial viscose fiber accounts for 1% of the total weight of the yarn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com