Vacuum insulating layer with a plurality of unit cavities

A technology of vacuum insulation layer and insulation layer, which is applied in the direction of heat preservation, pipeline protection, pipeline protection through heat insulation, etc. It can solve the problems that insulation products cannot ideally meet its requirements, achieve practicability and economy, and strengthen structural strength , enhance the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

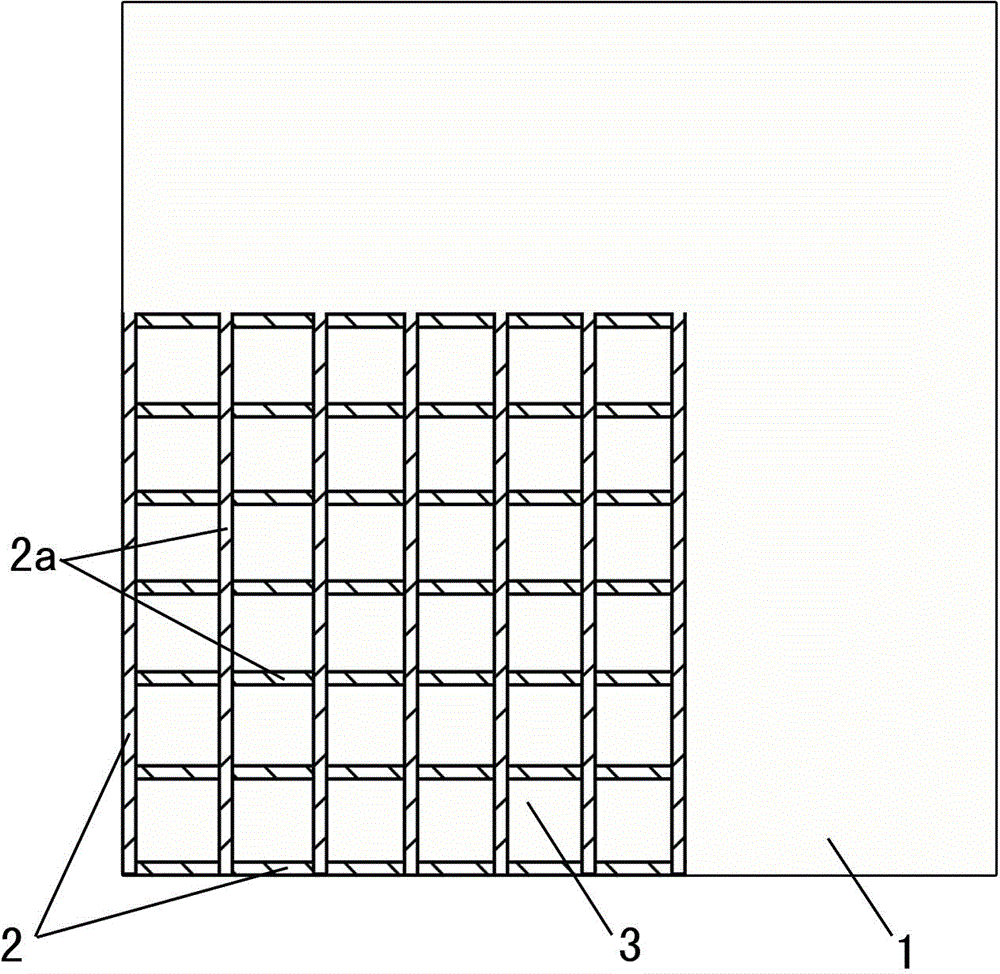

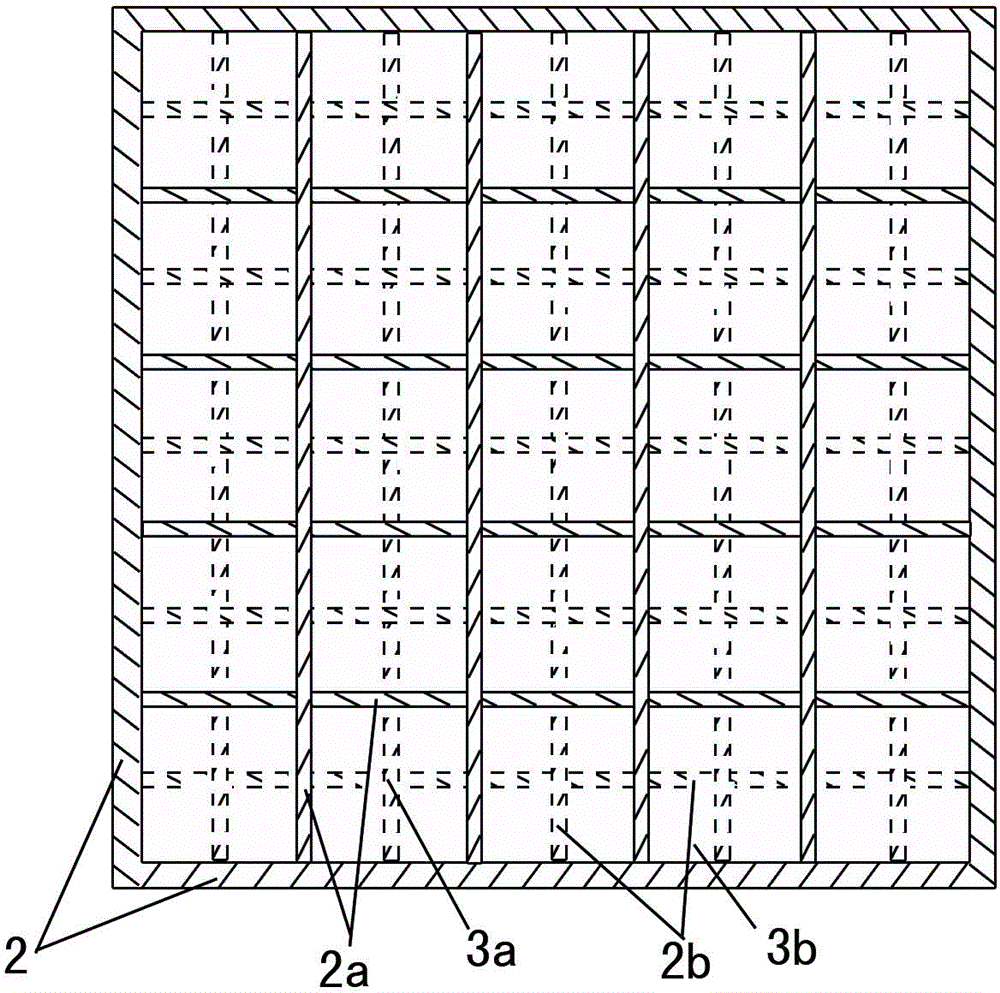

[0033] A vacuum insulation layer with multiple unit cavities

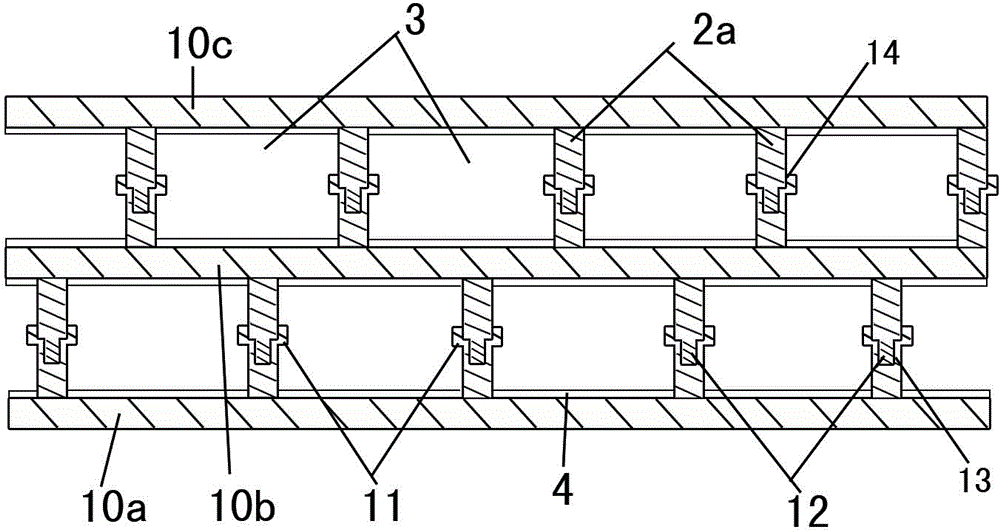

[0034] Refer to attached figure 1 , 2, 3, 4, and 5, the vacuum insulation layer with multiple unit cavities of the present invention includes an insulation layer body 1, and the insulation layer body 1 shown includes a sealing layer arranged on the front side 10a and the back side 10c and is connected to the front side 10a and the side wall 2 connected to the periphery of the sealing layer of the back side 10c, a closed main cavity is formed between the side wall and the sealing layer of the front side 10a and the back side 10c, and criss-cross seals are arranged in the main cavity. Strip 2a, the sealing strip 2a isolates the main cavity formed by the sealing layer of the front side 10a and the back side 10c and the side wall 2 into a plurality of independent airtight unit cavities 3, so that the main cavity form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com