Preparation method for diaphragm with low friction coefficient

A technology with a small friction coefficient and a diaphragm, which is applied in the direction of electrical components, electrochemical generators, circuits, etc., can solve the problems of reducing melt fluidity, rough diaphragm surface, unfavorable polymer processing and molding, etc. The effect of neat, convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a diaphragm with a small coefficient of friction, comprising the steps of:

[0027] (1) Stir the polyolefin resin, lubricant and other additives evenly through a mixing mixer to obtain a mixture;

[0028] (2) adding the mixture to a cast extrusion device for casting to prepare a cast base film;

[0029] (3) Putting the prepared casting base film into a constant temperature oven for heat treatment;

[0030] (4) After the heat treatment is completed, the heat-treated base film is stretched longitudinally to prepare a microporous separator with a microporous structure and qualified performance.

[0031] In the present invention, the lubricant can be selected from one or more of polyolefin commonly used lubricants such as calcium stearate, ethylene bisstearamide, stearamide, high boiling point paraffin wax, microcrystalline paraffin wax, PP wax, PE wax, etc. A lubricating additive.

[0032] Among them, the significance of adding lubricant is: (1) t...

Embodiment

[0051] A diaphragm is prepared by using the method of the present invention. One or more lubricants with lubricating effect are added before the diaphragm is formed. The diaphragm is made of polypropylene (PP) with a thickness of 16 μm, and its performance is qualified in all aspects.

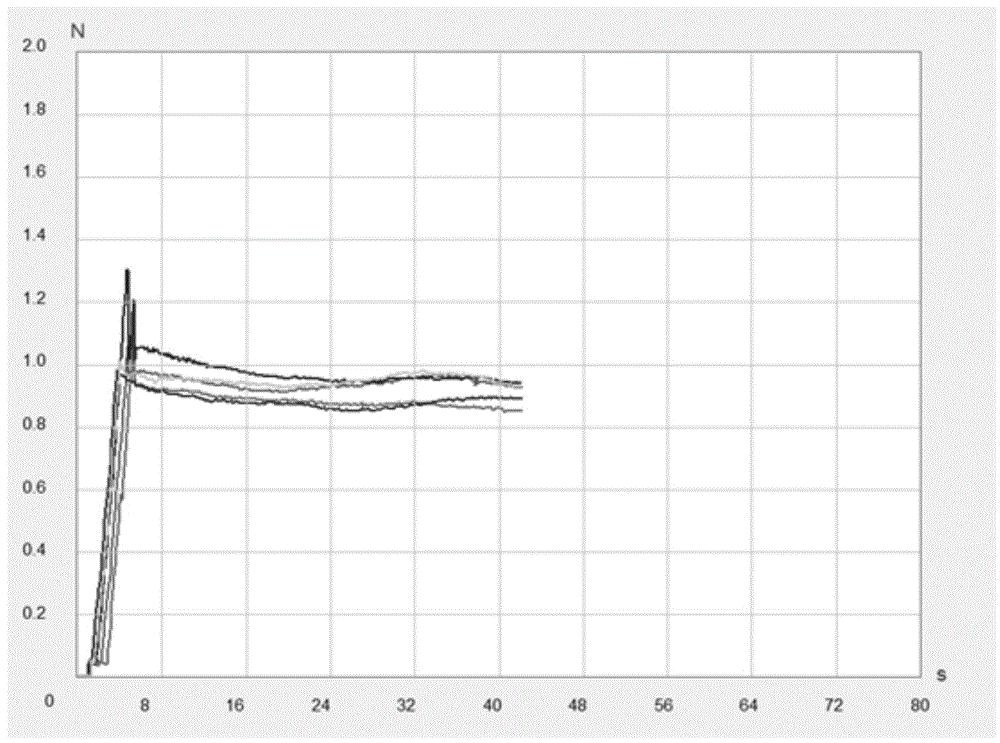

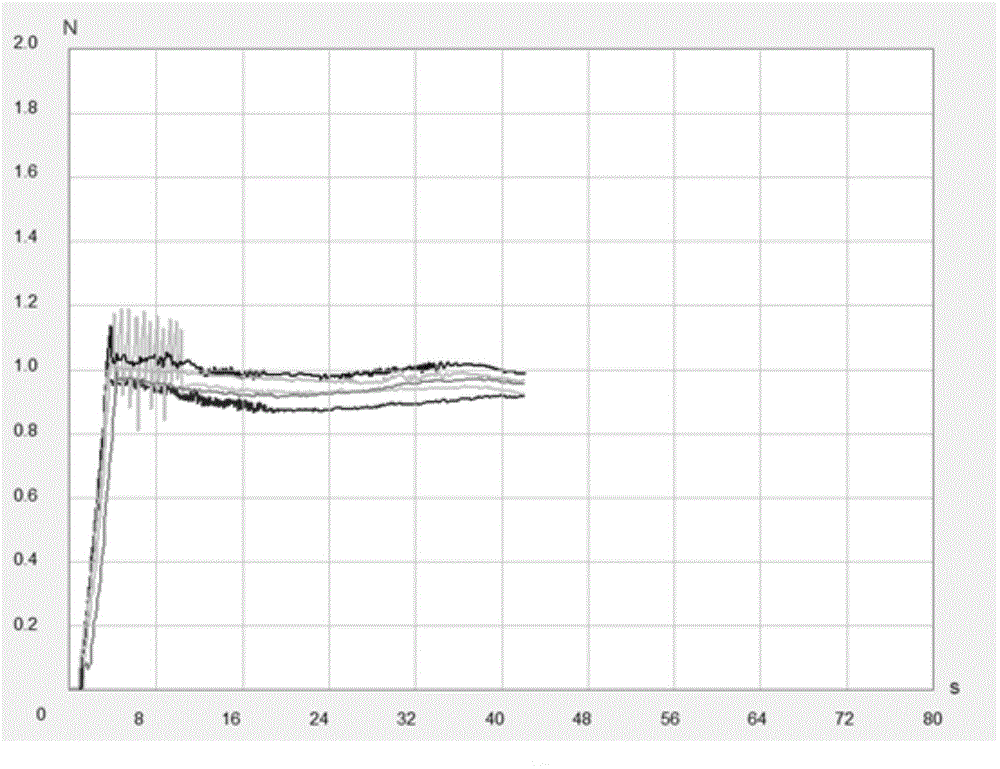

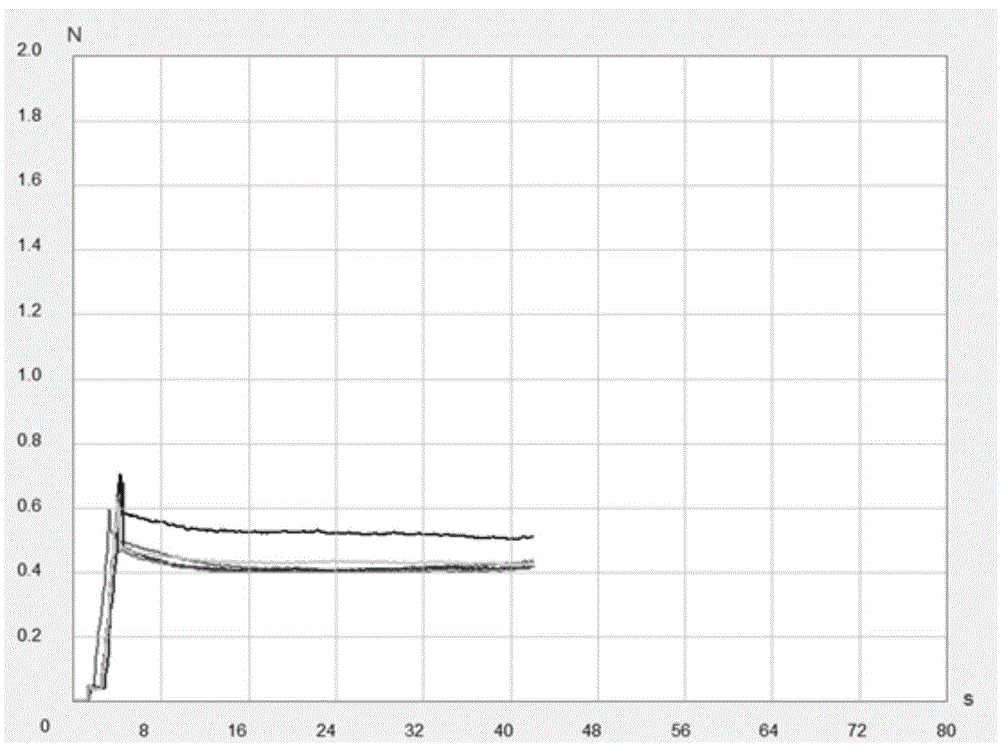

[0052] Cut out 5 groups of diaphragm samples with a size of 120 mm in width and 150 mm in length along the MD and TD directions of the diaphragm respectively, gently clamp the diaphragm samples to the sample holding block, and fix the stainless steel sheet on the sliding platform. After the above actions are completed Gently place the sample holding block on the stainless steel sheet to contact it, and connect the sample holding block to the spring pin seat with the tension sensor with a steel wire rope. Among them, the mass of the sample holding block is selected as 200g, the test speed is 100mm / min, and the number of tests is 5 times. After setting the experimental parameters, the test can st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com