Lost foam digital forming machine

A forming machine and lost foam technology, applied in the directions of casting mold components, casting molding equipment, other manufacturing equipment/tools, etc., can solve the problems of rapid manufacturing of complex lost foam, blank deformation, etc., to achieve high hardness and shear strength, reduce Manufacturing cycle, penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

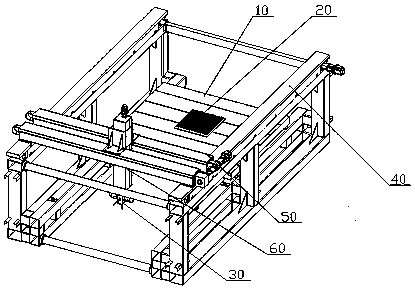

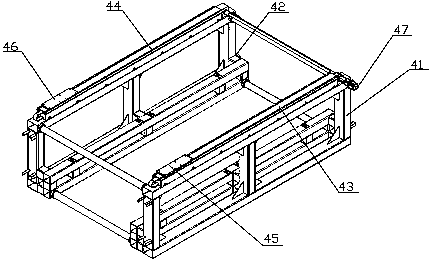

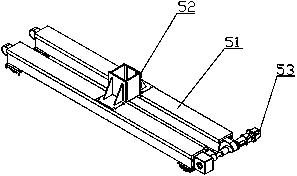

[0021] see Figure 1 to Figure 4 , schematically shows a preferred embodiment of a lost foam digital forming machine provided by the present invention. As shown in the figure, the lost foam digital forming machine includes a multi-axis motion system, a workbench 10, and a needle-implanted fixed platform 20 . Milling and cutting system 30 .

[0022] The multi-axis kinematic system is used to mount the machining tools provided by the milling and cutting system 30 . The milling and cutting motions of the milling cutter and the cutter are controlled by controlling the action of the multi-axis motion system, so that the lost foam placed on the needle-planting fixed platform 20 is manufactured into a pattern. It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com