Hole cluster end face mechanical sealing structure like sensitive plant type

An end-face mechanical seal, mimosa technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of insufficient pressure and wear resistance, not suitable for bidirectional rotation, limited dynamic pressure effect, etc., and achieve extended use. Longevity, excellent stability, effect of improving lubricating state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

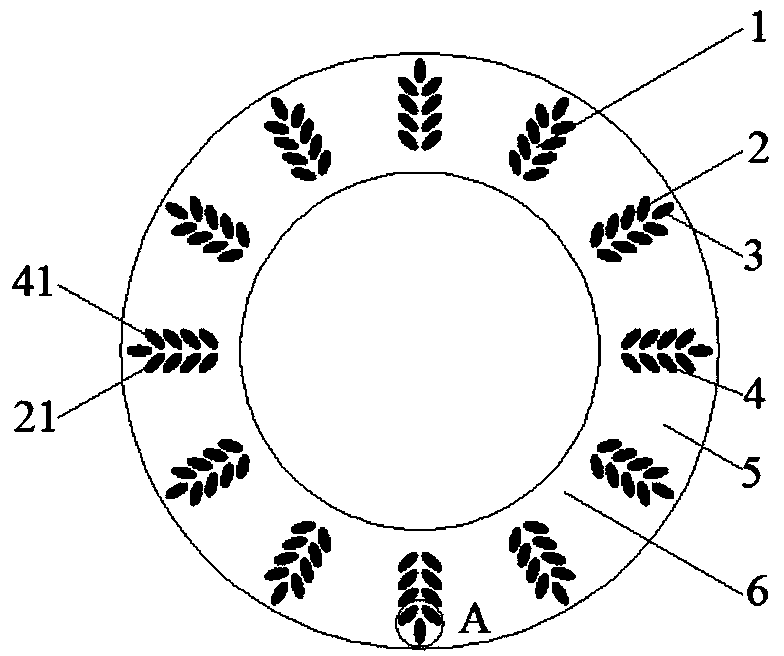

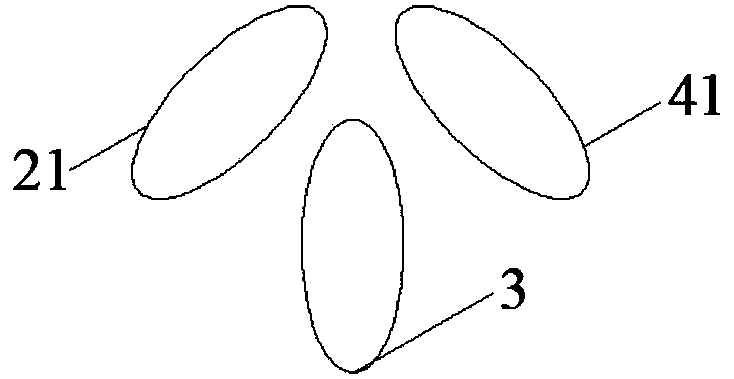

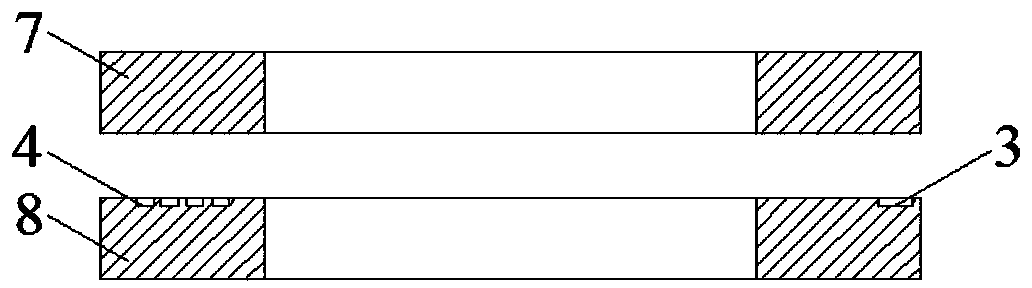

[0018] A mimosa-like hole cluster end face mechanical seal structure, including a moving ring 7 and a static ring 8, one side of the end faces of the moving ring 7 and the static ring 8 is the high pressure side, namely upstream, and the other side is the low pressure side, namely downstream , at least one end surface of the moving ring 7 or the static ring 8 is evenly distributed along the circumference along the circumferential direction, and the dynamic pressure type hole clusters 2 and 4 composed of mimosa-shaped hole clusters are composed of directional millimeter-scale hole clusters. Hole cluster structure 1, the Mimosa-like hole cluster 1 constitutes an annulus, the annulus is located upstream of the end face, the downstream of the annulus is provided with a smooth plane annular sealing dam 6, and the two mimosa-like The non-open area between the circumferential direction of the pore cluster structure constitutes the sealing weir 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com