High-performance soft-type cable-carrier optical cable and manufacturing method of high-performance soft-type cable-carrier optical cable

A high-performance and soft technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of performance degradation of insulation and sheath materials, tensile force, torsion and bending fatigue, short service life of optical signal transmission, etc., and achieve good practical value. and promote the value, improve the anti-stretching ability, and improve the effect of anti-stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

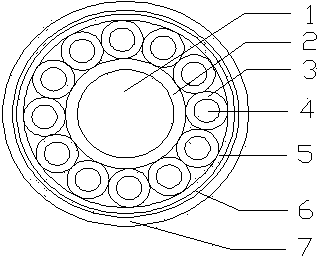

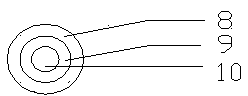

[0022] Such as figure 1 As shown, a high-performance flexible tow optical cable, including an aramid fiber reinforced core 1, a polyurethane protective layer 2, a polyurethane outer layer 3, an optical fiber unit 4, a polyurethane inner sheath 5, a polyester braided layer 6, and a polyurethane outer sheath A sleeve 7, a loose tube 8, an aramid filament filling layer 9 and an optical fiber 10, the aramid reinforcing core 1 is provided with a polyurethane protective layer 2, and a plurality of optical fiber units 4 are included between the polyurethane protective layer 2 and the polyurethane inner sheath 5, Each optical fiber unit 4 is provided with a polyurethane outer sheath 3, and the polyurethane inner sheath 5 is sequentially covered with a polyester yarn braid 6 and a polyurethane outer sheath 7. The optical fiber unit 4 is sequentially composed of a loose tube 8 , Aramid filament filling layer 9 and optical fiber 10. The loose tube 8 is high-performance polyurethane. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com