A process for producing ammonia synthesis gas and a related front-end of an ammonia plant

A technology of ammonia synthesis gas and synthesis gas, applied in hydrogen/synthesis gas production, hydrogen production, inorganic chemistry, etc., can solve the problems of increasing the size of equipment and HTS outflow cooling section, expensive cryogenic purification, increasing natural gas volume, etc. , so as to avoid the risk of condensation, make the device cheap, and break through the bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

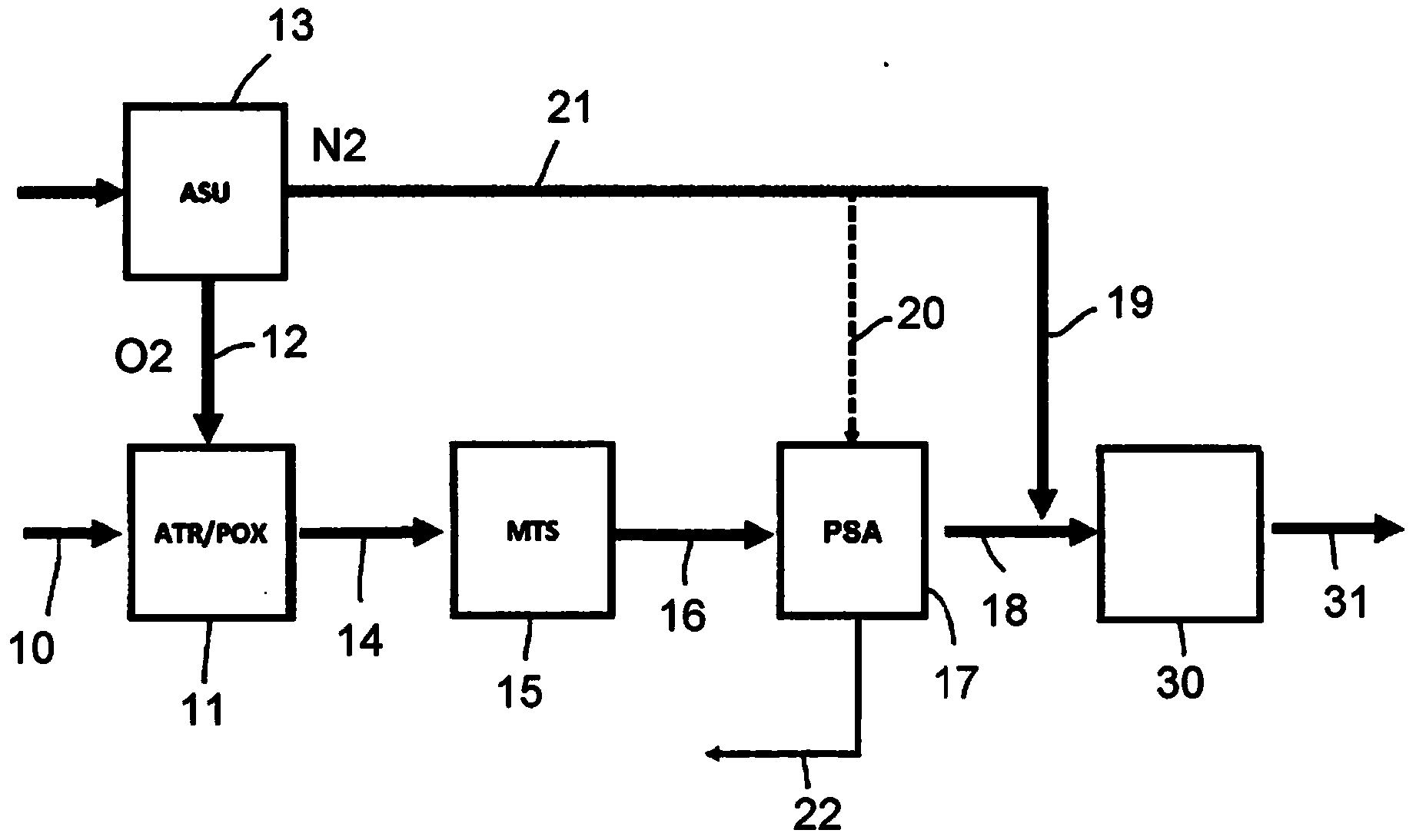

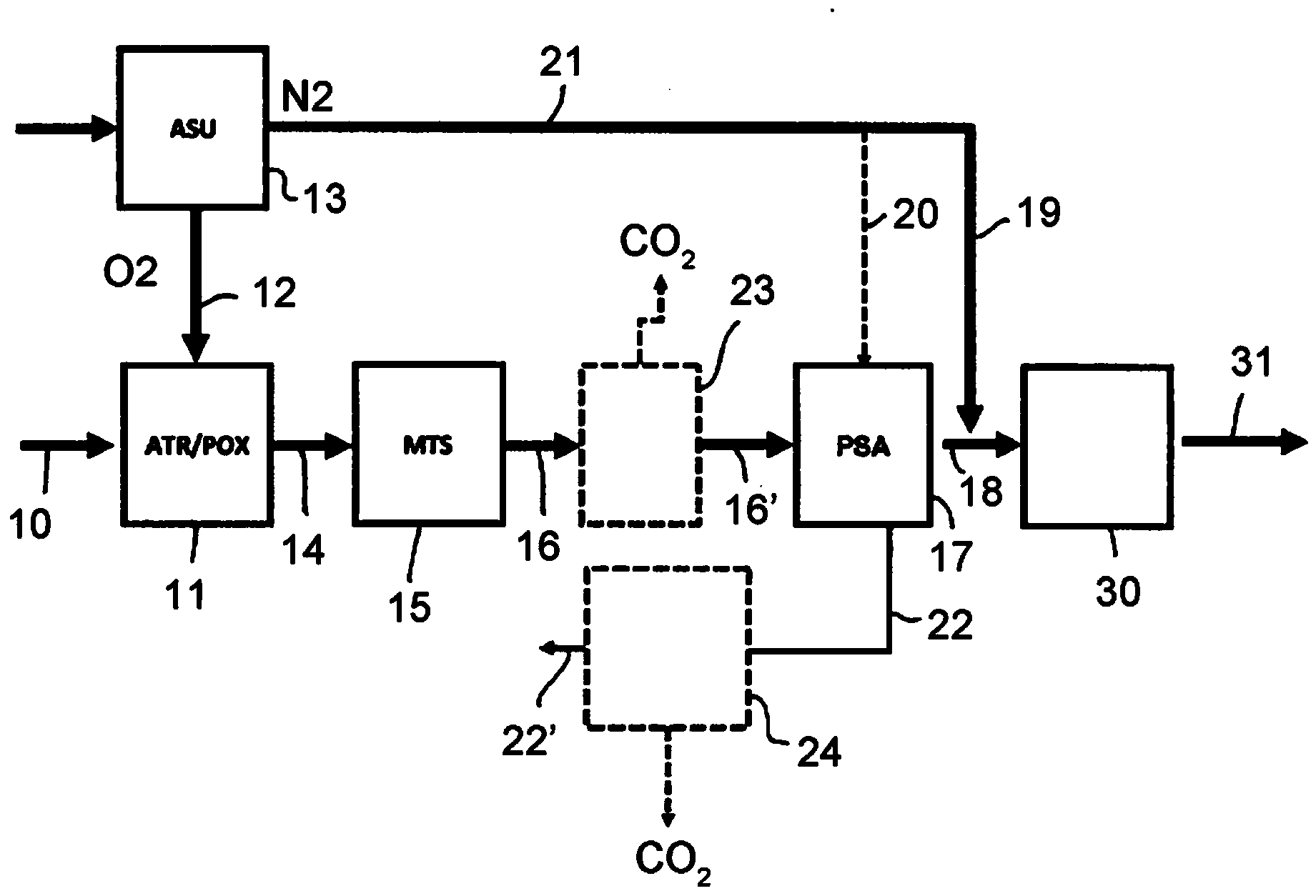

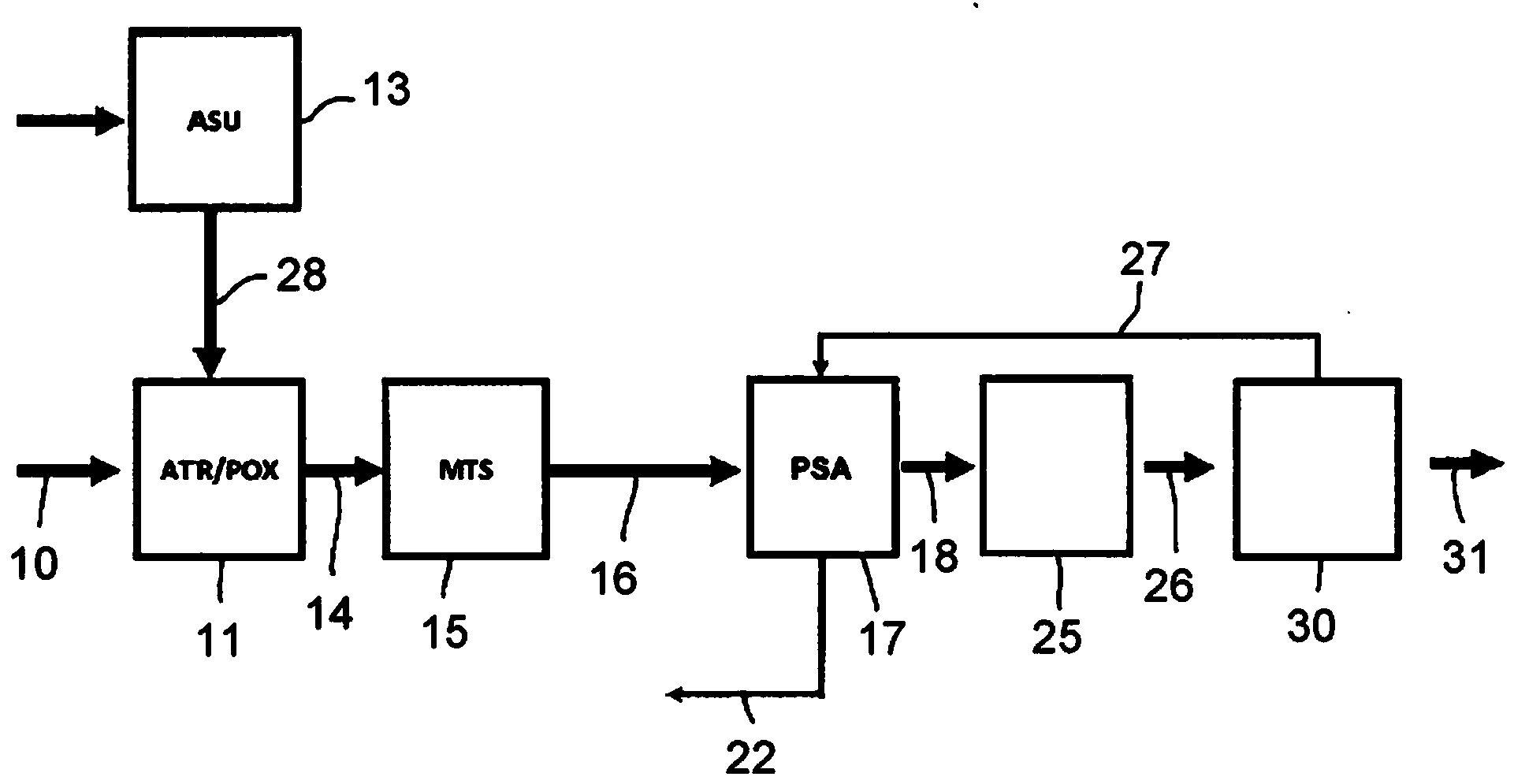

Method used

Image

Examples

example

[0068] The table below compares an example of a theoretical ammonia plant with a production capacity of 5,000 metric tons per day. The table compares the two cases:

[0069] (1) With primary reformer and secondary reformer, high temperature shift, low temperature shift, CO 2 Traditional designs for removal (MDEA scrubbing) and methanation;

[0070] (2) Design according to the present invention.

[0071]

[0072]

[0073] The example shows that the new design requires nearly 30% less power for syngas compression than the prior art. This means 30% more capacity can be achieved with the same compression power. Also the present invention does not require any steam reformer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com