Double-wind corn peeling and polishing machine

A technology of polishing machine and corn, which is applied in the direction of grain husking, grain finishing, and grain processing, etc., which can solve the problems of insufficient compaction, slow feeding speed, high maintenance cost, etc., and achieve easy manufacturing and processing, convenient operation and maintenance, The effect of simplifying the air path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

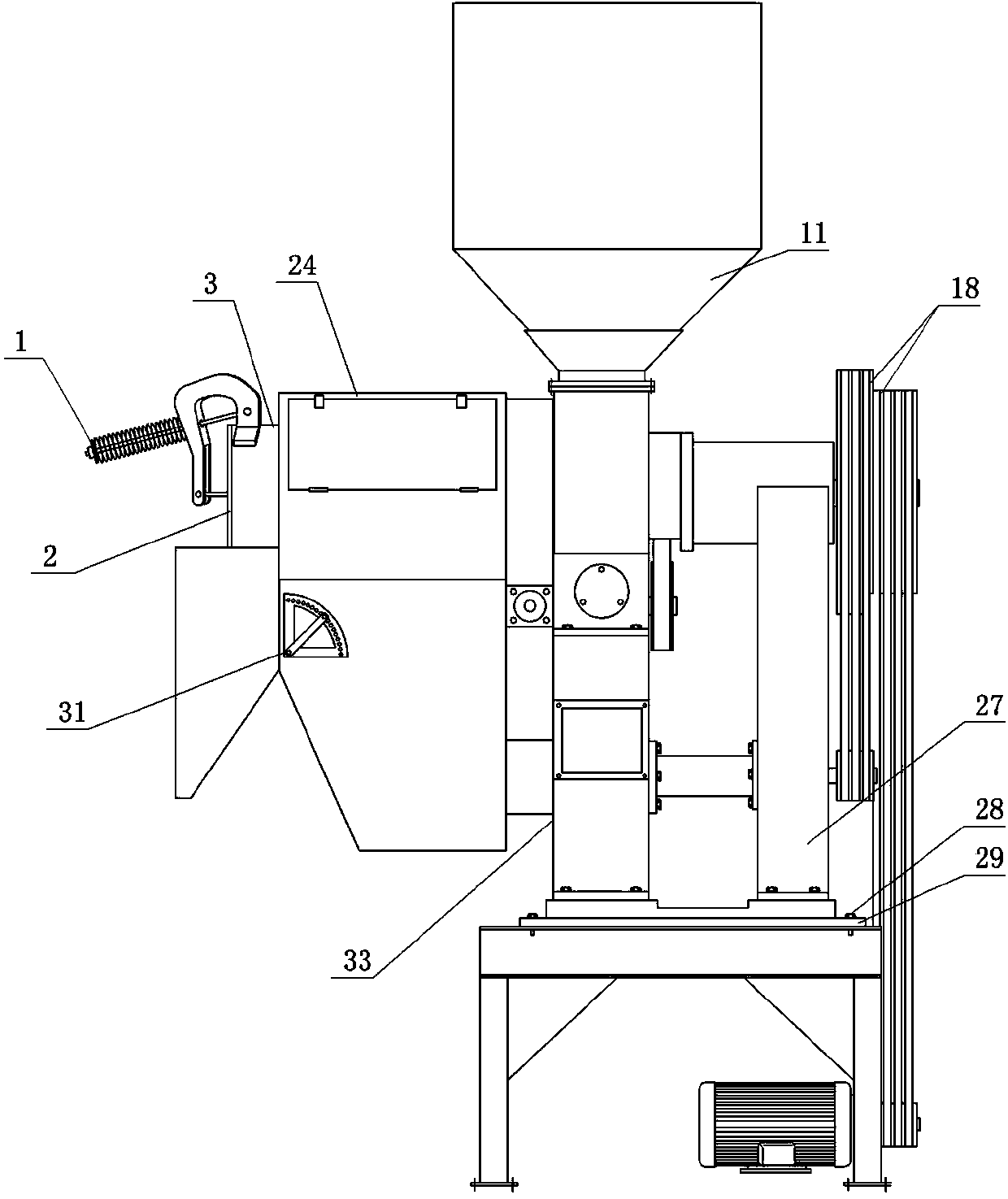

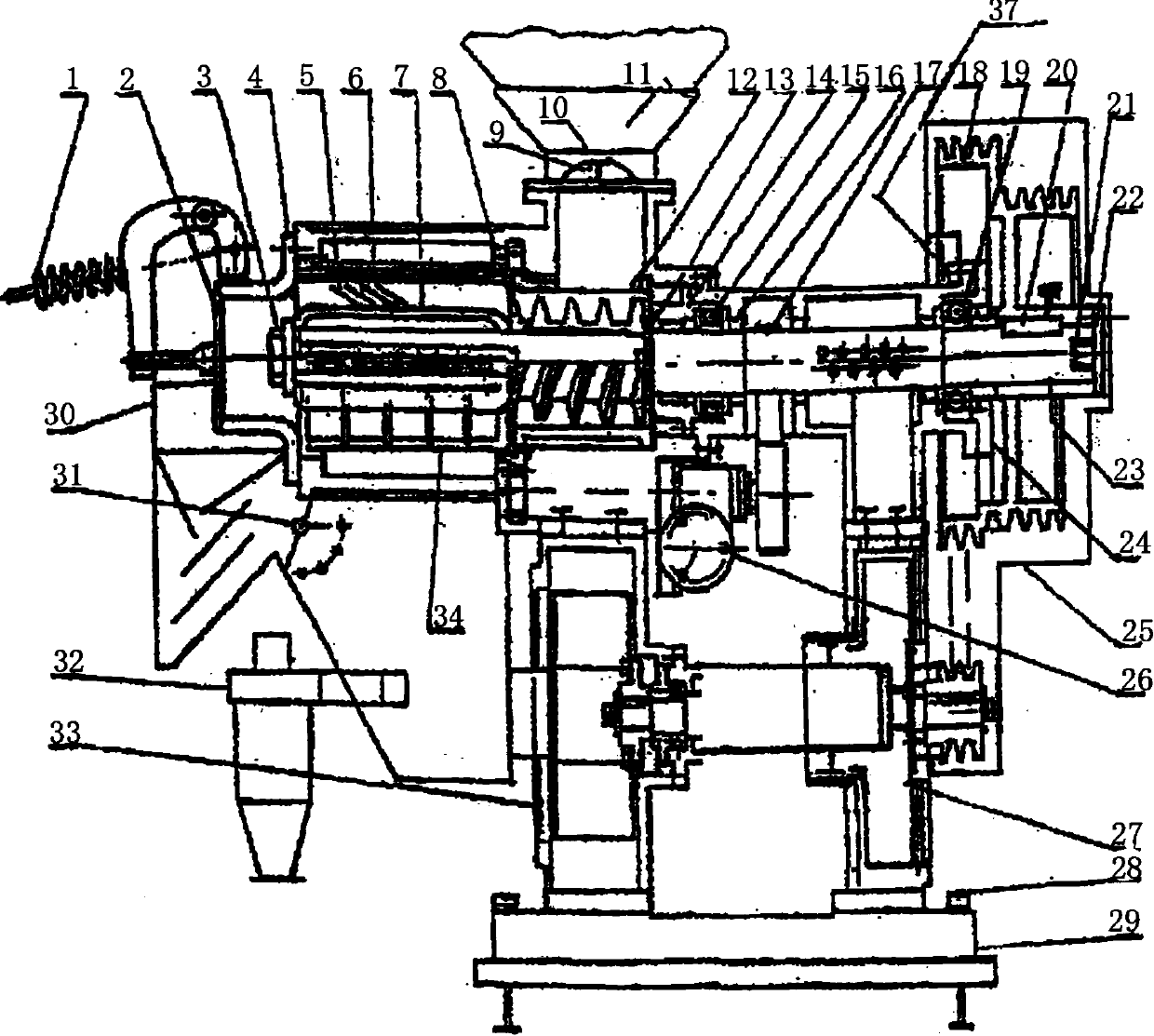

[0022] Embodiment 1: a kind of corn double wind peeling polishing machine, see figure 1 with figure 2 , including a frame, a motor, a main shaft 17, a grinding chamber 24, an inlet hopper, an outlet hopper 4, a screw propeller and fans and other components. Wherein, the upper side of the frame is equipped with a transverse main shaft through bearings and oil seals. One end of the main shaft 17 is equipped with a belt pulley and is connected with the motor transmission. On the upper side of the screw propeller, the discharge hopper is located at the end of the milling chamber.

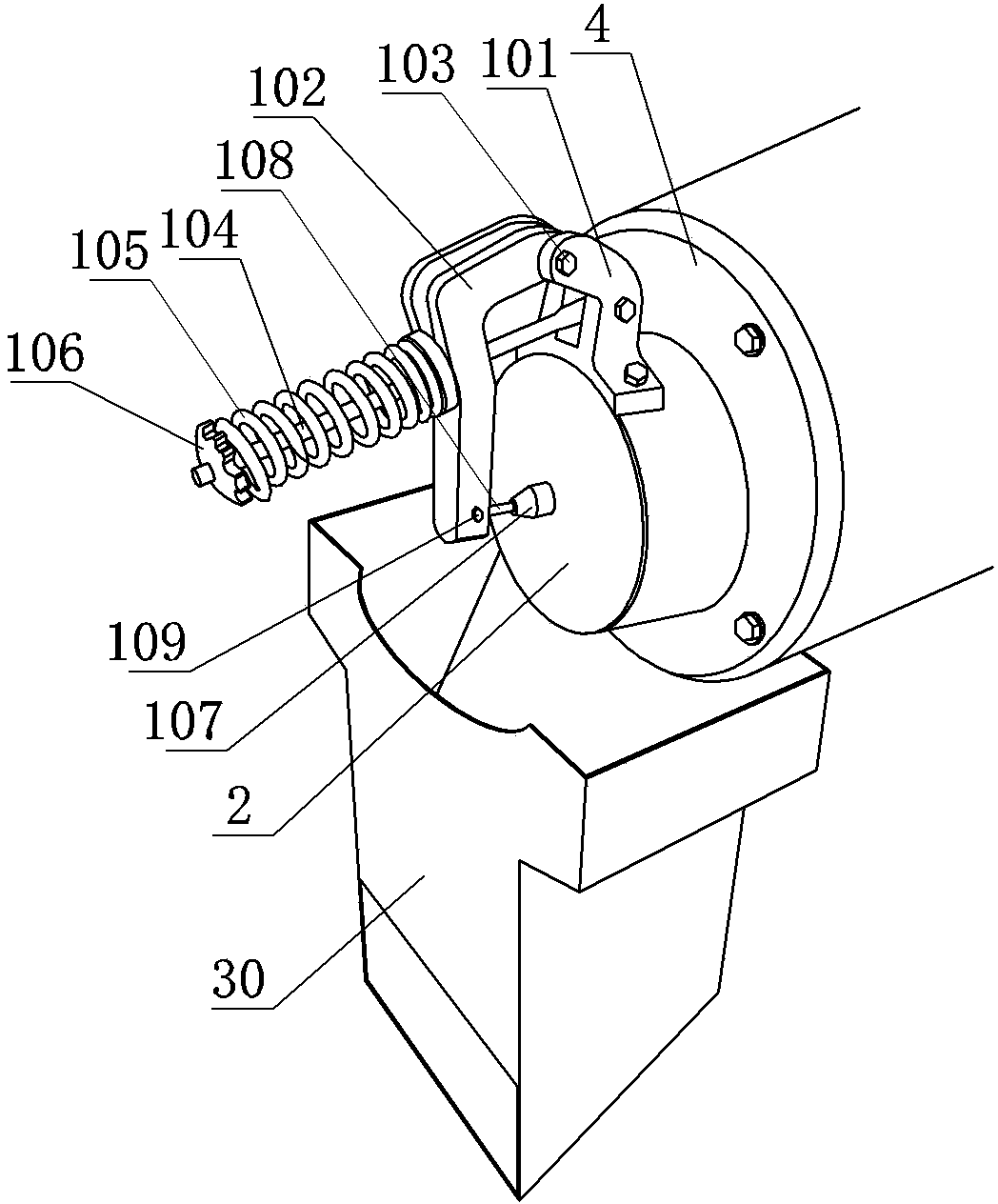

[0023] see figure 2 with Figure 4 , the roller 7 is located in the chamber, the roller 7 is fixed on the outside of the main shaft 17 end, and an annular cavity is formed between the inner cavity of the roller and the main shaft; the side wall of the roller 7 is provided with only Two axially parallel blade seams 36; the upper side of the roller 7 is provided with a fixed sieve, and the lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com