Pulse water jet coating peeling and finishing equipment

A water jet and finishing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. The effect of improving the technical level, improving the processing speed and efficiency, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

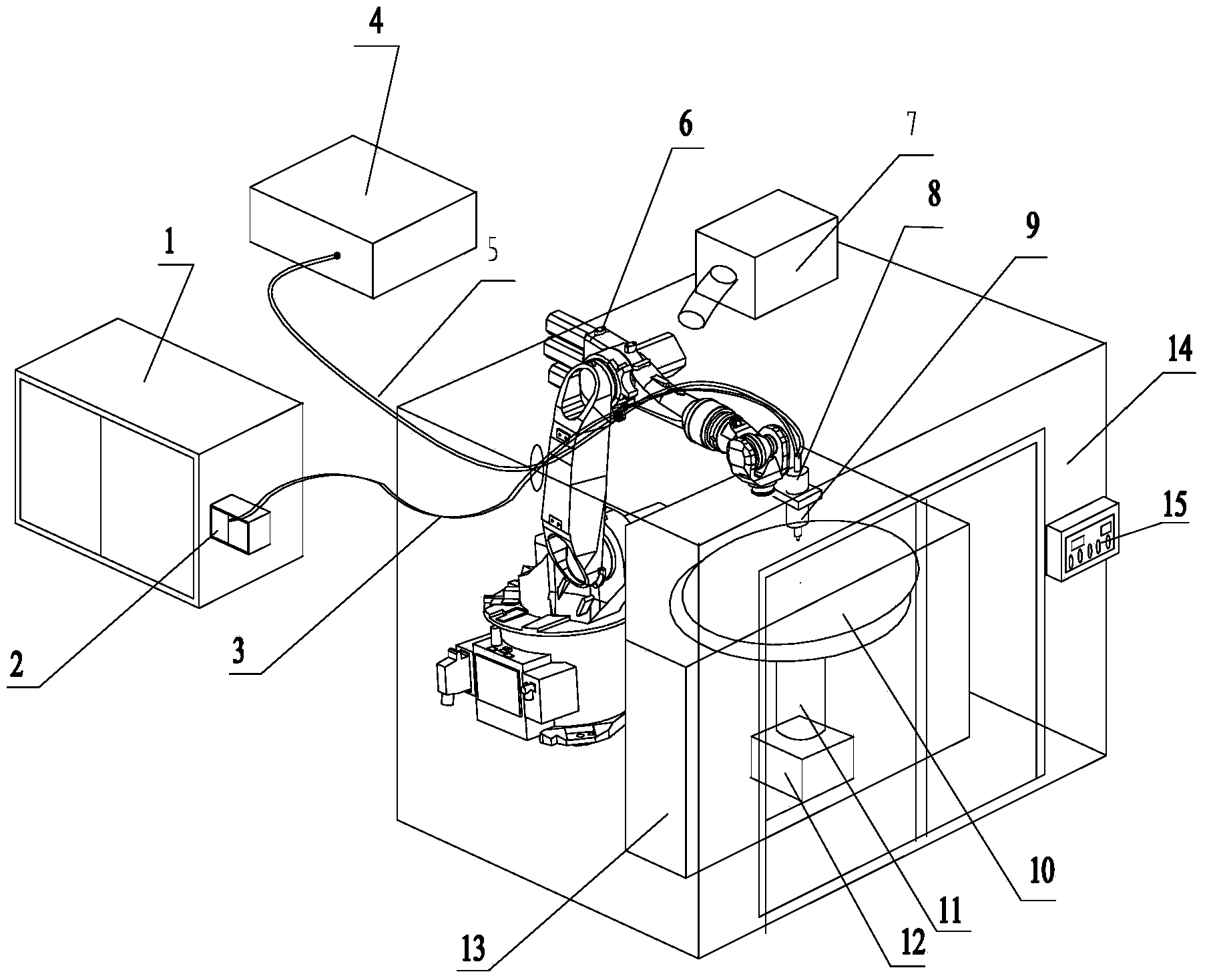

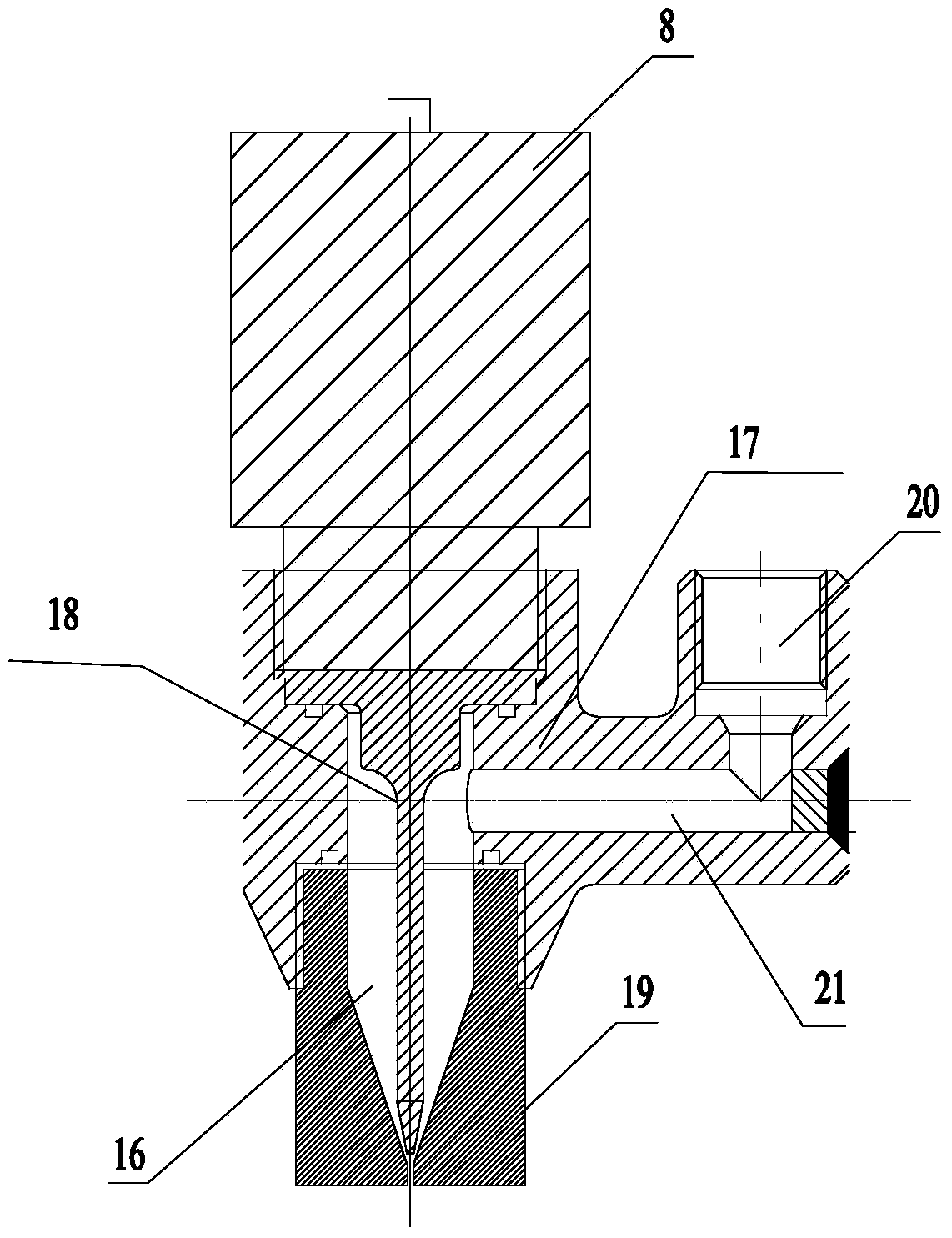

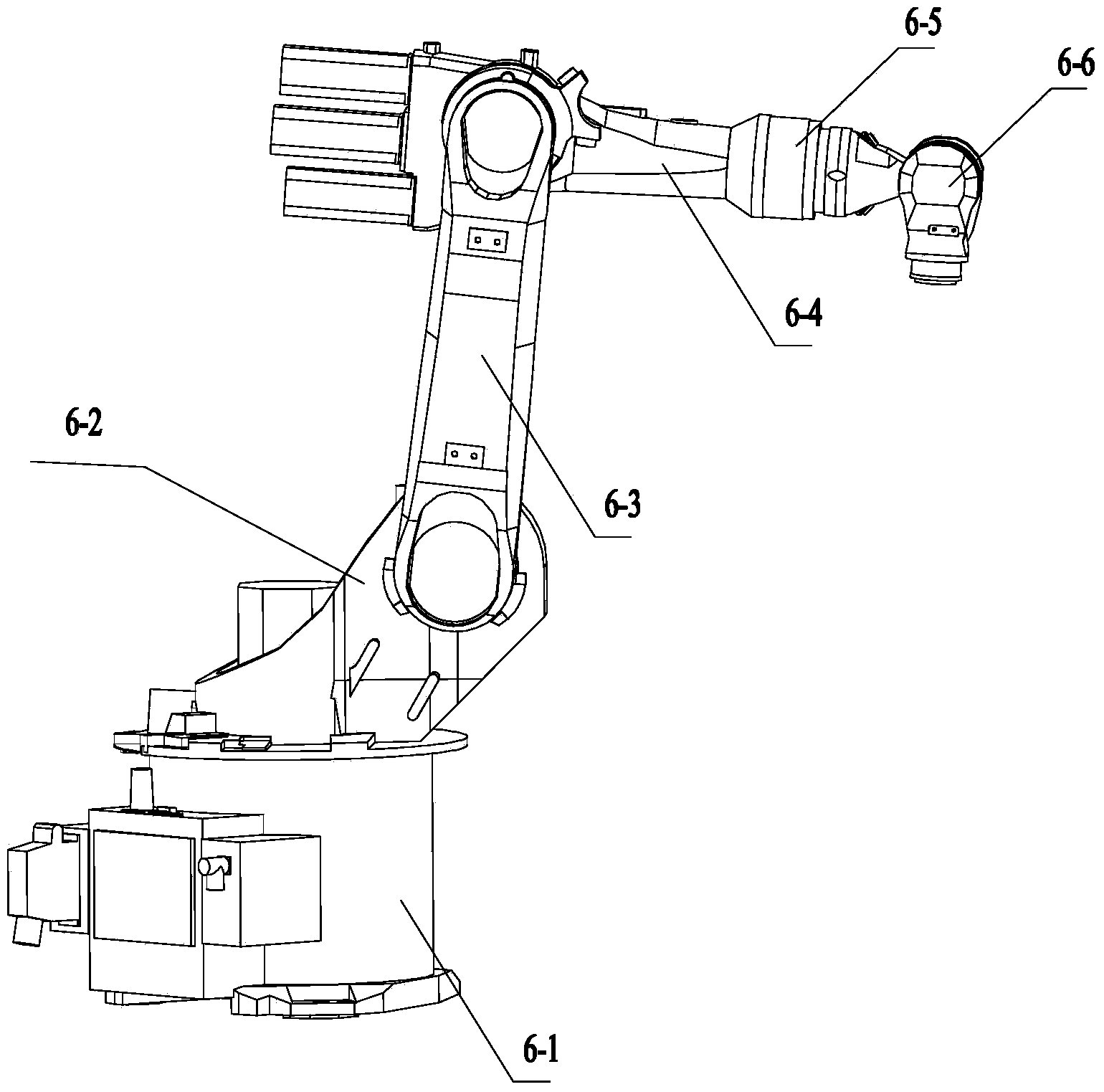

[0016] figure 1 Including high-pressure water generator 1, pressure regulator 2, high-pressure pipeline 3, ultrasonic generator 4, cable 5, robot actuator 6, first axis 6-1, second axis 6-2, third axis 6-3, fourth axis 6-4, fifth axis 6-5, sixth axis 6-6, mist absorber 7, ultrasonic transducer 8, nozzle device 9, workpiece clamping rotating platform 10, rotating axis 11 , servo motor 12, collection box 13, shield 14, switch control box 15, water jet channel 16, nozzle body 17, horn 18, water jet nozzle 19, nozzle body water inlet 20, nozzle body high pressure water channel 21, etc. .

[0017] Such as figure 1 As shown, the present invention is a kind of pulsed water jet coating stripping finishing equipment, comprises guard cover 14, and described guard cover 14 interior is provided with collecting box 13, and the side of collecting box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com