Fibreboard preparation plant with leveling device

A fiberboard and equipment technology, applied in the field of fiberboard preparation equipment, can solve problems such as uneven thickness of fiber paving, achieve the effects of good leveling effect, strong operability, and avoiding repeated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

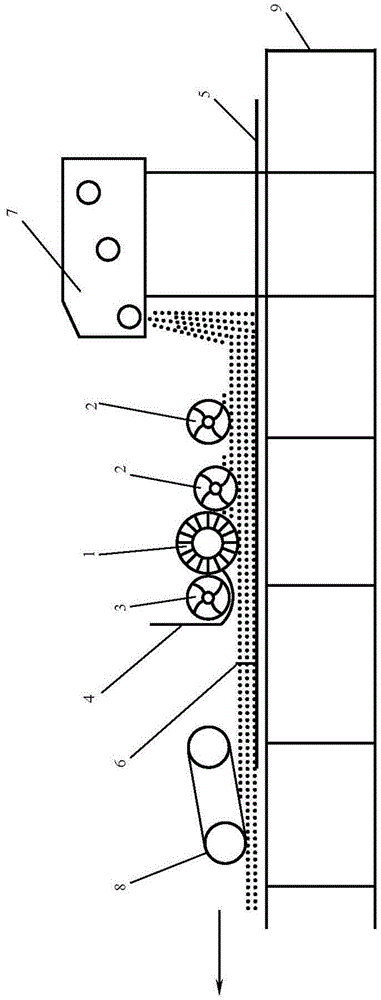

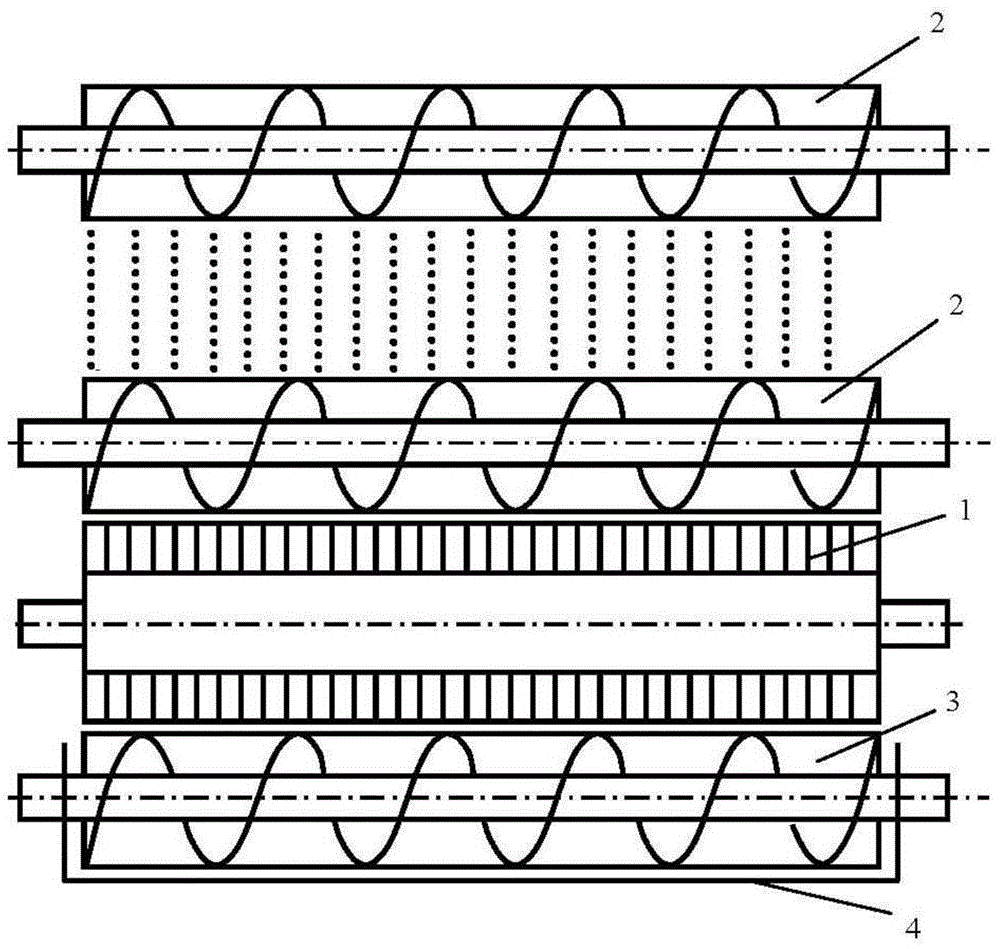

[0019] Example: Fibreboard production plant with leveling device, such as figure 1 ,and figure 2 As shown, it includes a base 9, and a conveyor belt 5 driven by a conveying drive mechanism is arranged on the base 9. A laying station and a rolling station are arranged above the conveyor belt, and it is characterized in that the conveyor belt 5 The top is also provided with a leveling station between the laying station and the rolling station, and the leveling station is provided with a leveling roller 1 that is arranged on the base 9 and driven by a power drive mechanism. The rollers are in clearance fit with the upper surface of the conveyor belt.

[0020] The leveling station is also provided with a front auger 2, and the front auger 2 is arranged in front of the leveling roller 1 station.

[0021] The leveling station is also provided with a rear auger 3, and the rear auger 3 is arranged behind the leveling roller 1 station.

[0022] The leveling station is also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com