Isostatic-pressing dry-powder molding device

A molding device and isostatic pressing technology, applied in the field of static pressing machines, can solve the problems of shrinkage cavities, unstable thermal properties, low sintering shrinkage rate, and high product density, and achieve fast molding speed, small sintering shrinkage rate, and high product density. high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

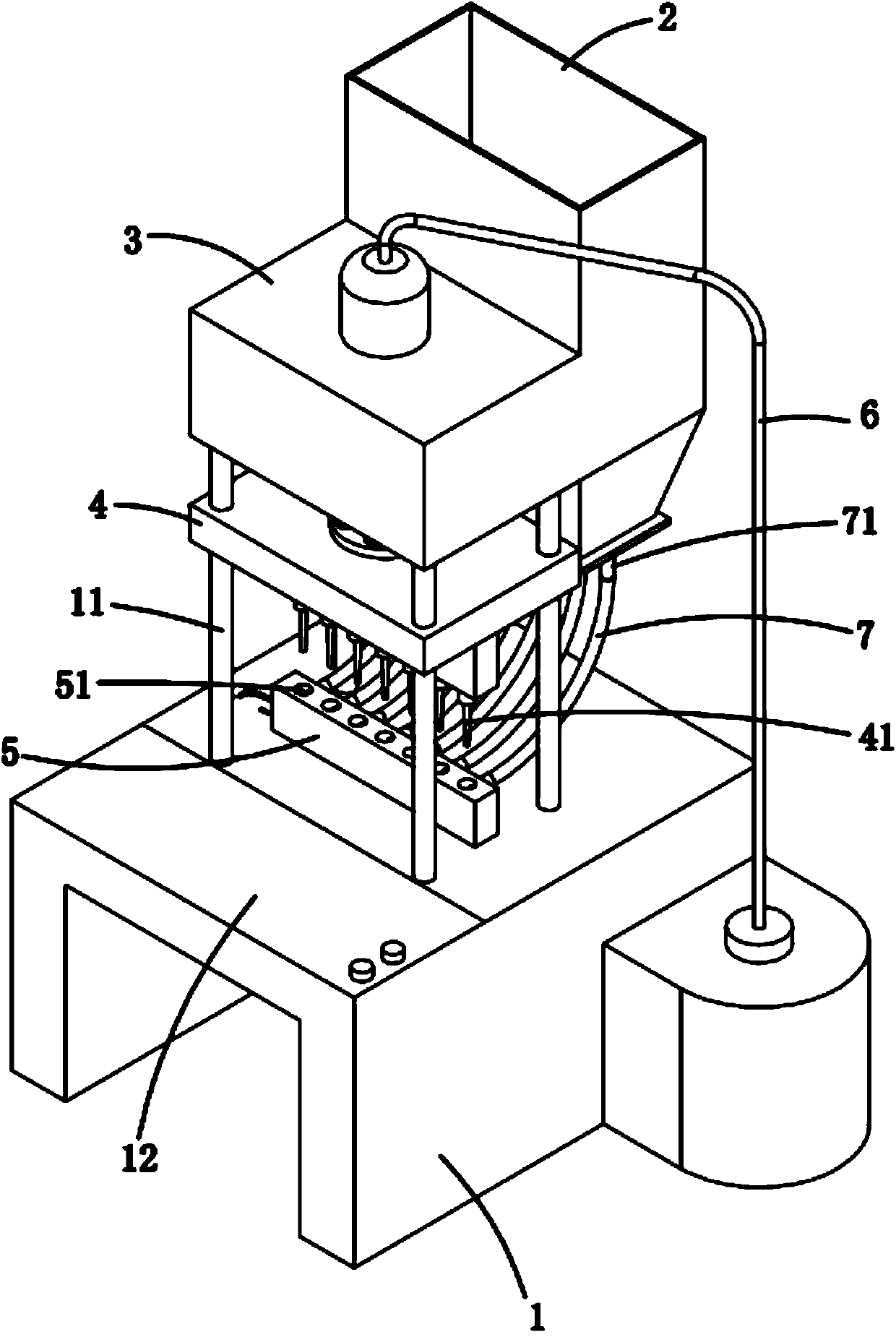

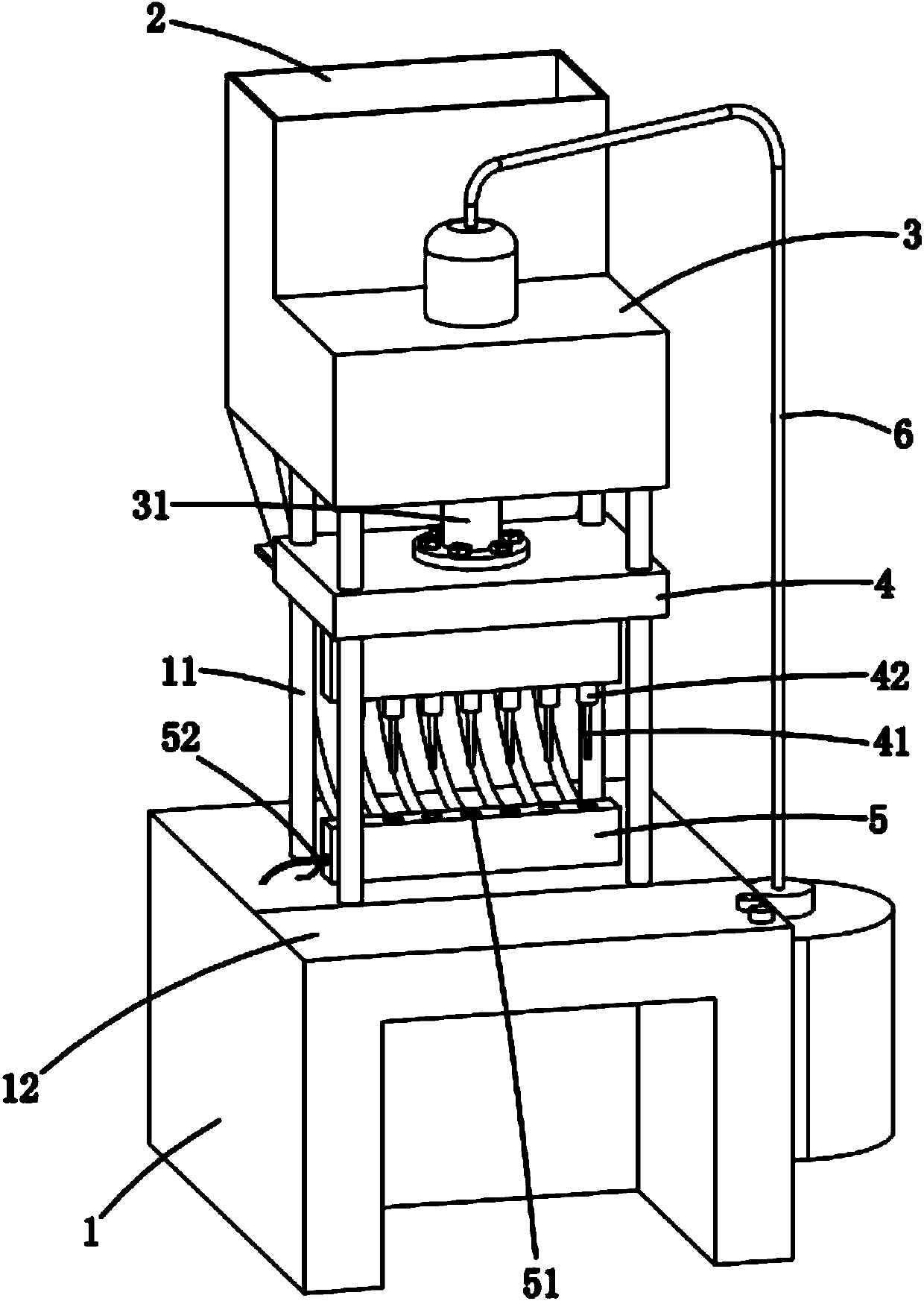

[0019] Refer to attached figure 1 , an isostatic dry powder molding device, including a mounting base 1, a hopper 2 for containing powder, a hydraulic cylinder 3, an upper mold 4, a lower mold 5, and a PLC control system or an upper computer DCS system, a PLC control system or an upper computer The DCS system of the machine is controlled manually or automatically through the control panel installed on the mounting base 1. The hydraulic cylinder 3 is connected to the control panel through the pipeline 6, and the four corners of the bottom are equipped with 1 on the guide column 11; the upper mold 4 is fixedly connected with the piston 31 of the hydraulic cylinder 3, and its four corners are all worn on the guide column 11 and can move up and down along the guide column 11. 4. A plurality of punches 41 are vertically and evenly distributed on the bottom surface, and the punches 41 are adapted to the center hole of the processed spark plug; Dies 5 are evenly distributed with cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com