High-concentration industrial wastewater treatment method

A technology of industrial wastewater and treatment methods, applied in the field of water treatment, can solve problems such as adverse effects on human health and the environment, limited use range, mutagenicity, etc., to improve the effect of acidification and hydrolysis, reduce sludge discharge, enhance fluidization and The effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

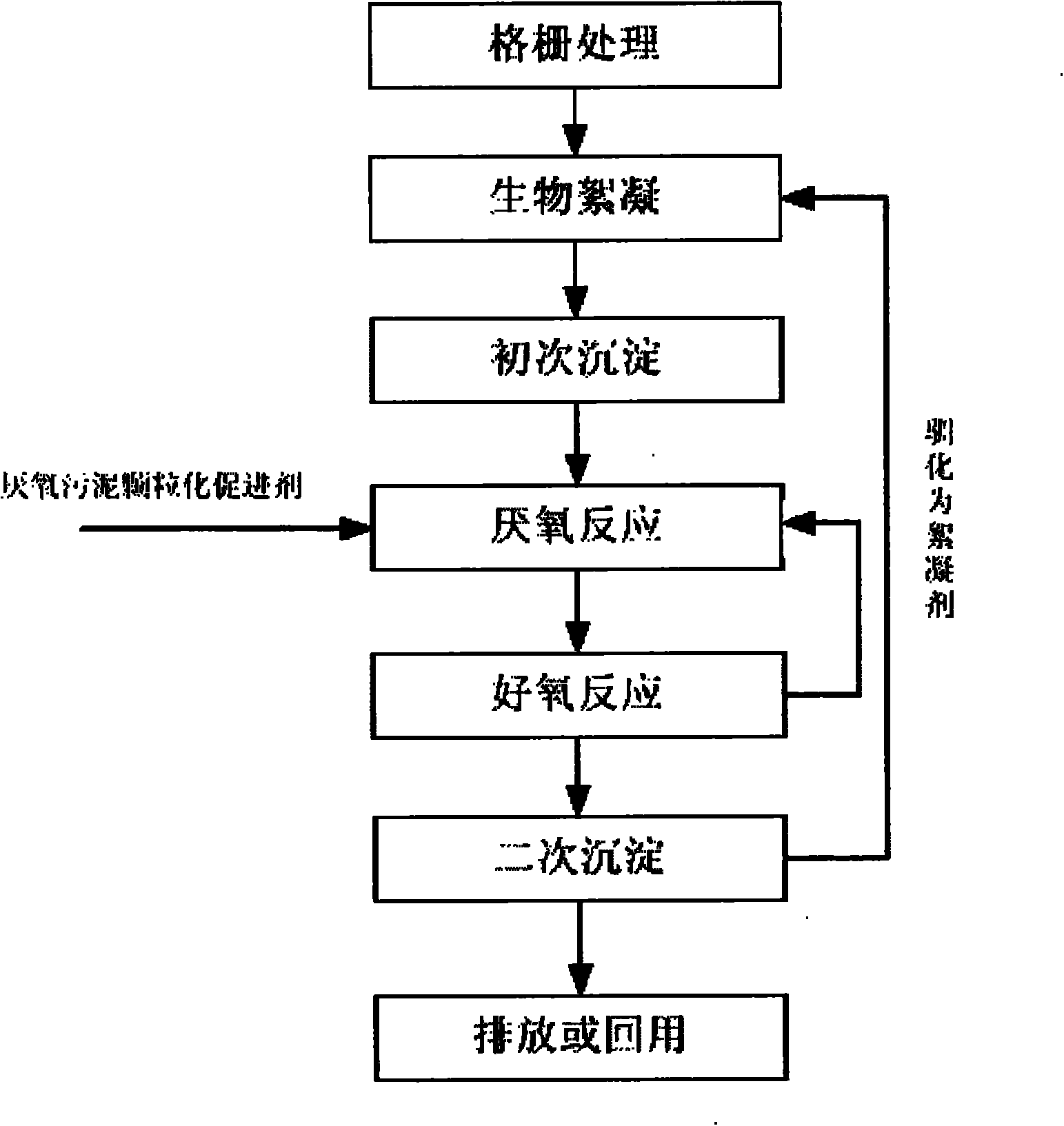

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 As shown, the present invention proposes a kind of high-concentration industrial waste water treatment method, it is characterized in that comprising the following steps:

[0019] Step 1: After the sewage is treated with a grid to filter out large waste, it is sent to the bioflocculation tank for bioflocculation treatment, and the bioflocculation tank is added with a bioflocculant and an accelerator for improving the activity of the bioflocculant;

[0020] Step 2: Send the flocculated sewage into the primary sedimentation tank, and then send it to the anaerobic reaction device and the aerobic reaction device for anaerobic reaction treatment and aerobic reaction treatment after the primary sedimentation, and then enter the secondary sedimentation tank. Wherein, sludge particles and anaerobic sludge particle accelerator are added in the anaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com