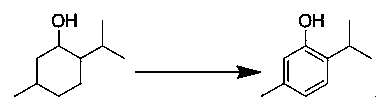

Thymol synthesis method

A technology of thymol and its production method, which is applied in the field of biomedicine, can solve problems such as low value, and achieve the effects of less by-products, improved quality, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 catalyst preparation

[0024] Weigh 7.2 g of activated carbon and soak it overnight with 30 ml of 15% HNO3 solution, filter and wash with boiling water to remove residual acid until the pH of the system is greater than or equal to 7. The wet activated carbon was dried at room temperature, then placed in an oven at 393K to dry overnight, and then calcined in a muffle furnace at 673-773K for 5 hours, and set aside. Dissolve 18g of nickel nitrate and 0.3g of sodium silicate in an appropriate amount of water and add to the above activated carbon. Stir at room temperature for 30 min. Then the solvent was distilled off under reduced pressure, and the solid was dried in an oven at programmed temperature (300K-400K) for 10h. The dried solid was reduced with hydrogen at 650-720k for 5h, and the Ni / Na2SiO3 catalyst supported by activated carbon was obtained after reduction.

Embodiment 2

[0025] Example 2 Catalyst Preparation

[0026] Weigh 7.5 g of activated carbon and soak it overnight with 30 ml of 15% HNO3 solution, filter and wash with boiling water to remove residual acid until the pH of the system is greater than or equal to 7. The wet activated carbon was dried at room temperature, then placed in an oven at 393K to dry overnight, and then calcined in a muffle furnace at 673-773K for 5 hours, and set aside. Dissolve 25g of nickel nitrate and 0.7g of sodium silicate in an appropriate amount of water and add them to the above activated carbon. Stir at room temperature for 30 min. Then the solvent was distilled off under reduced pressure, and the solid was dried in an oven at programmed temperature (300K-400K) for 10h. The dried solid was reduced with hydrogen at 650-720k for 5h, and the Ni / Na2SiO3 catalyst supported by activated carbon was obtained after reduction.

Embodiment 3

[0027] Example 3 catalyst preparation

[0028] Weigh 7.5 g of activated carbon and soak it overnight with 30 ml of 15% HNO3 solution, filter and wash with boiling water to remove residual acid until the pH of the system is greater than or equal to 7. The wet activated carbon was air-dried at room temperature, then placed in an oven at 393K to dry overnight, and then roasted in a muffle furnace at 673K for 5 hours for later use. Dissolve 25g of nickel nitrate and 0.3g of sodium silicate in an appropriate amount of water and add them to the above activated carbon. Stir at room temperature for 30 min. Then the solvent was distilled off under reduced pressure, and the solid was dried in an oven at programmed temperature (300K-400K) for 10h. The dried solid was reduced with hydrogen at 650k for 5h, and the Ni / Na2SiO3 catalyst supported by activated carbon was obtained after reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com