Device for directly manufacturing conductive film at room temperature and method thereof

A conductive thin film, room temperature technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of poor conductivity, high use cost for end users, restricting large-scale popularization and application, and meet the requirements of reducing the environment , Improve production and application efficiency, simplify the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

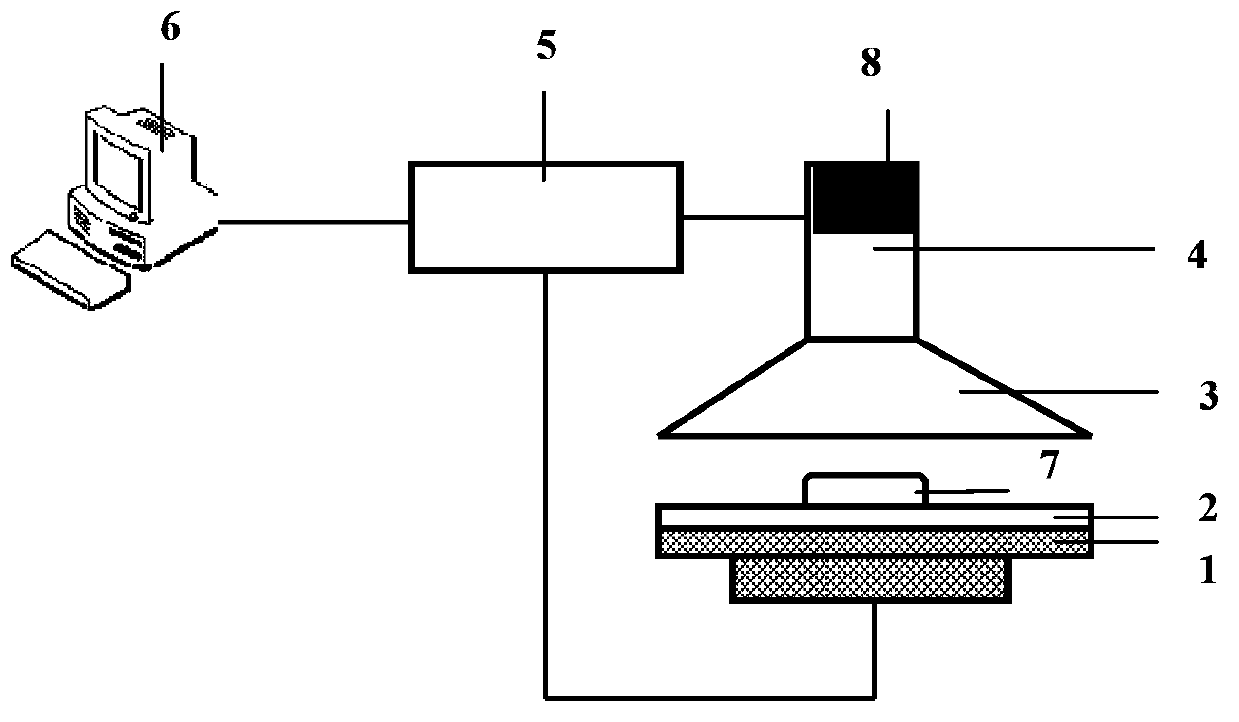

[0024] Such as figure 1 , a spray film-forming device for directly making conductive thin films at room temperature of the present invention, comprising: a substrate platform 1, a substrate 2, a field effect control function module 3, a member to be film-formed, a spray device 4, a numerical control system 5 and a PC 6 , the member to be formed into a film 7 , and the liquid metal ink 8 . The base platform supports and fixes the components to be filmed. The field effect control function module provides electromagnetic field environment and ultrasonic environment for the atomized droplets. The spray device is located above the base platform. The numerical control system co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com