Device and method for removing residual liquid from electroplated plate

A technology for removing devices and electroplating plates, applied in the direction of electrolysis process and electrolysis components, can solve problems such as unfavorable and limited production efficiency, and achieve the effects of easy maintenance, reduction of foreign objects and small particles, and easy installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

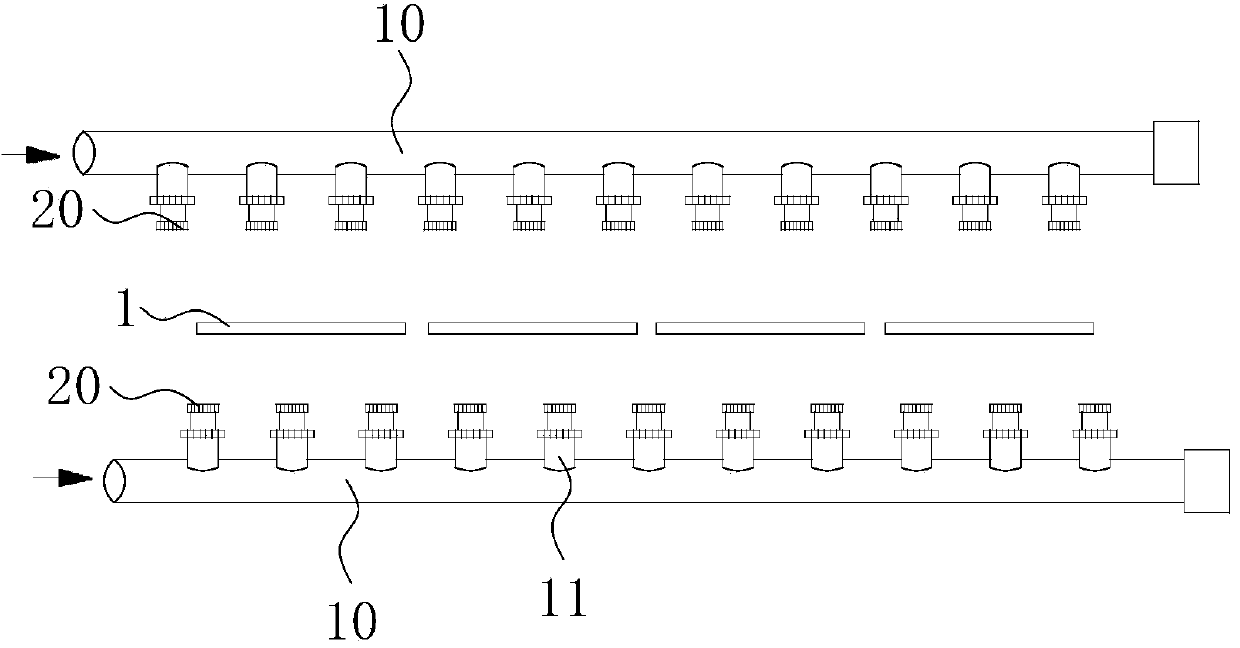

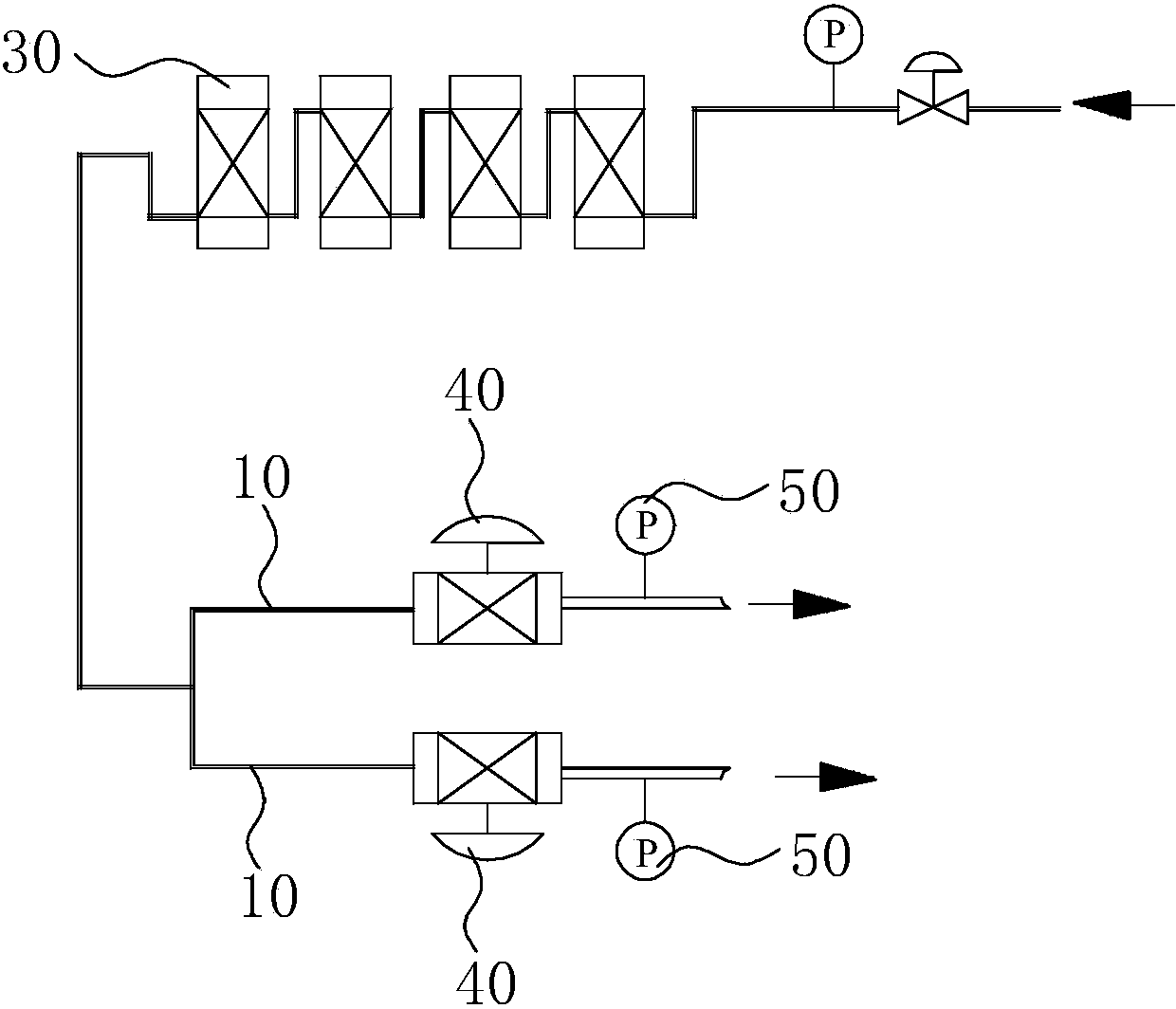

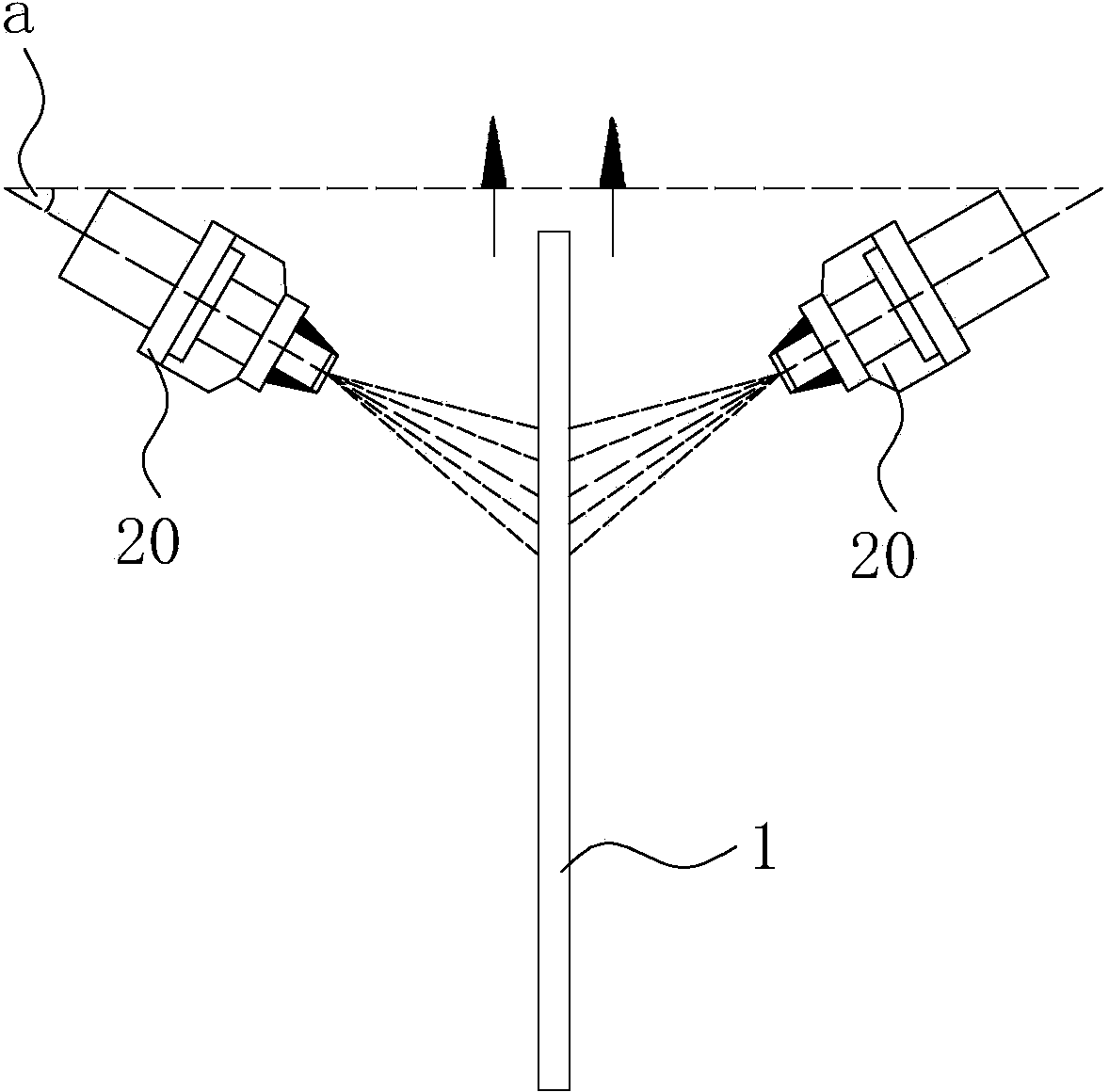

[0031] Such as Figure 1 to Figure 3 As shown, a device for removing residual liquid from an electroplating plate includes at least two air pipes 10, a plurality of nozzles 20, and an air filter 30, wherein two air pipes 10 are arranged on both sides above the electroplating tank, and a plurality of nozzles 20 are arranged at intervals The air pipe 10 is connected to the air pipe 10, the air pipe 10 is in communication with the high-pressure air source, and the air filter 30 is arranged between the air pipe 10 and the high-pressure air source.

[0032] The electroplating plate residual liquid removal device described in this embodiment can effectively reduce foreign matter and small particles in the high-pressure air by setting the air filter 30 to filter the high-pressure air, and prevent damage to the surface of the electroplating plate 1. The high-pressure air is sprayed to the On the electroplating plate 1, an impact force is generated on the residual liquid on the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com