Medical gauze bleaching high temperature wastewater waste heat recovery process

A high-temperature bleaching and waste heat recovery technology, applied in sustainable manufacturing/processing, textile and papermaking, liquid/gas/steam textile processing, etc. Achieve the effect of reducing the amount of steam used, improving social benefits and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

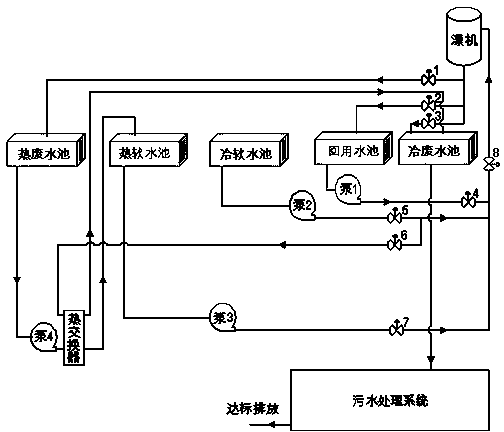

[0018] attached figure 1 It is a specific embodiment of the present invention. The invention discloses a process for recovering waste heat from medical gauze bleaching high-temperature wastewater, which comprises the following sequential steps:

[0019] 1. Pre-washing: run for 15 minutes at room temperature with water for refilling and then drain to the cold waste water pool;

[0020] 2. Bleaching: Filling with hot soft water, feeding: hydrogen peroxide 27.5%, 20g / l, caustic soda 99%, 10g / l, refining agent 2g / l, dispersant 3g / l, hydrogen peroxide stabilizer 3g / l, heat up to 120 degrees , the holding time is 50 minutes, then the temperature is lowered to 90 degrees and then drained to the hot waste water pool;

[0021] 3. Washing with warming water: charge hot soft water to run at room temperature to 75 degrees, keep warm for 10 minutes, and then drain to the hot waste water pool;

[0022] 4. Overflow water washing 1: After filling and returning water to run, continue to fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com