High-drop falling-type pipeline energy dissipation conveying system

A conveying system, high drop technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of damage to the receiving device, affecting the service life of the equipment, etc., to achieve easy implementation, improve operating life and scope of application , the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

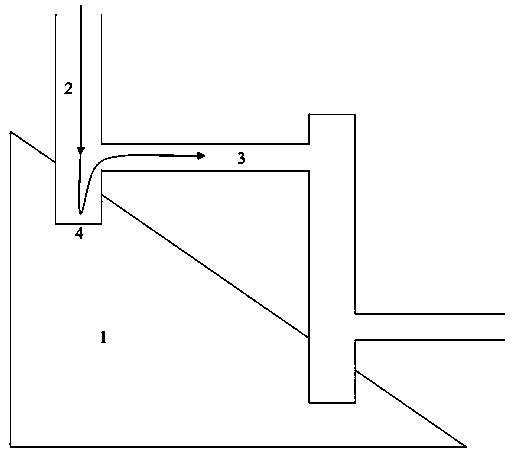

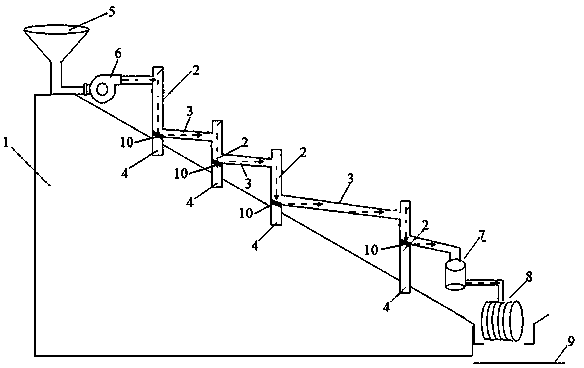

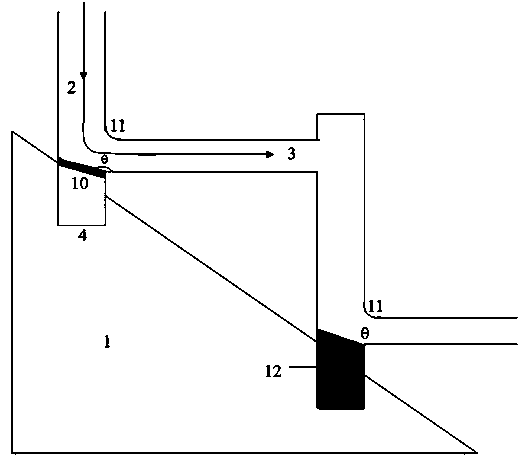

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

[0026] as attached figure 2 As shown, the high-drop drop pipeline energy dissipation conveying system of the present invention includes a concentration pool 5, a feeding pump 6, a drop pipeline 2, an energy dissipation pipeline 3, a distribution barrel 7, a filter 8 and a conveyor belt 9, the Concentration pool 5 is built on the top of a high-altitude mountain. The bottom outlet of the concentration pool 5 is connected to the pumping inlet of the feeding pump 6, and the pumping outlet of the feeding pump 6 is connected to the top of the drop pipe 2. For areas with high drop Environment, the pipeline conveying system includes a plurality of drop pipelines 2 and energy dissipation pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com