Ultrasonic-vibration activation-assisted sintering box-type resistance furnace

A box-type resistance furnace, ultrasonic vibration technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as unseen applications, and achieve the effects of wide adaptability, low porosity, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

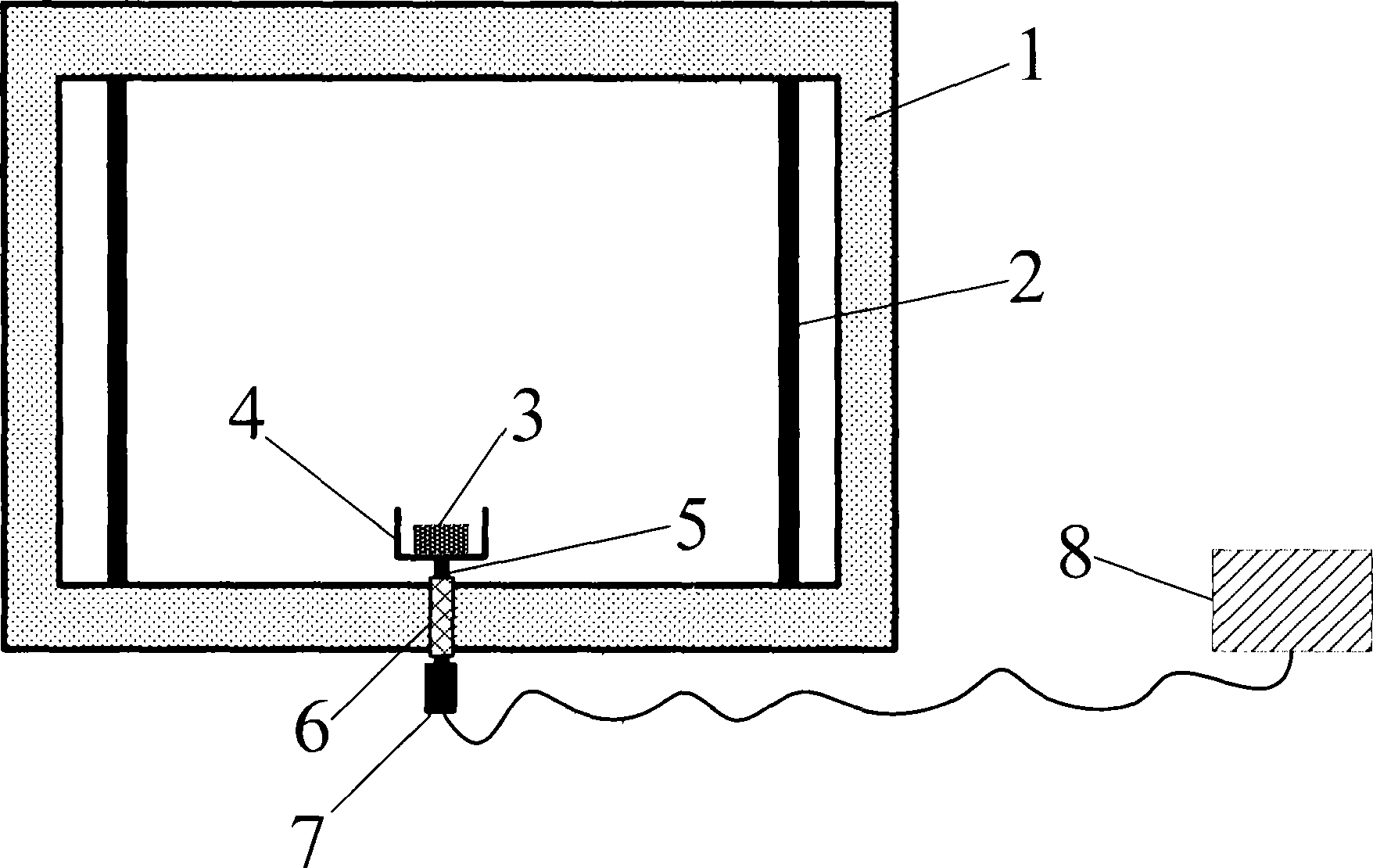

[0021] Such as figure 1 As shown in the front view schematic diagram of the bottom installation of the ultrasonic vibration activation auxiliary sintering resistance furnace ultrasonic device, the ultrasonic vibration activation auxiliary sintering resistance furnace ultrasonic device provided by the present invention is a bottom installation form, a hollow cylindrical annular alumina ceramic horn support frame 6 passes through the small hole at the bottom of the furnace shell 1, the alumina ceramic horn 5 passes through the horn support frame 6, and one end of the horn 5 in the furnace is connected to the alumina ceramic with a corresponding inner thread at the bottom through an external thread The crucible 4 is connected to an ultrasonic transducer 7 with a working frequency of 20 kHz by threading at one end outside the furnace of the horn 5 , and the ultrasonic transducer 7 is connected to the ultrasonic generator 8 through wires. Put the sample 3 to be fired into the cruci...

Embodiment 2

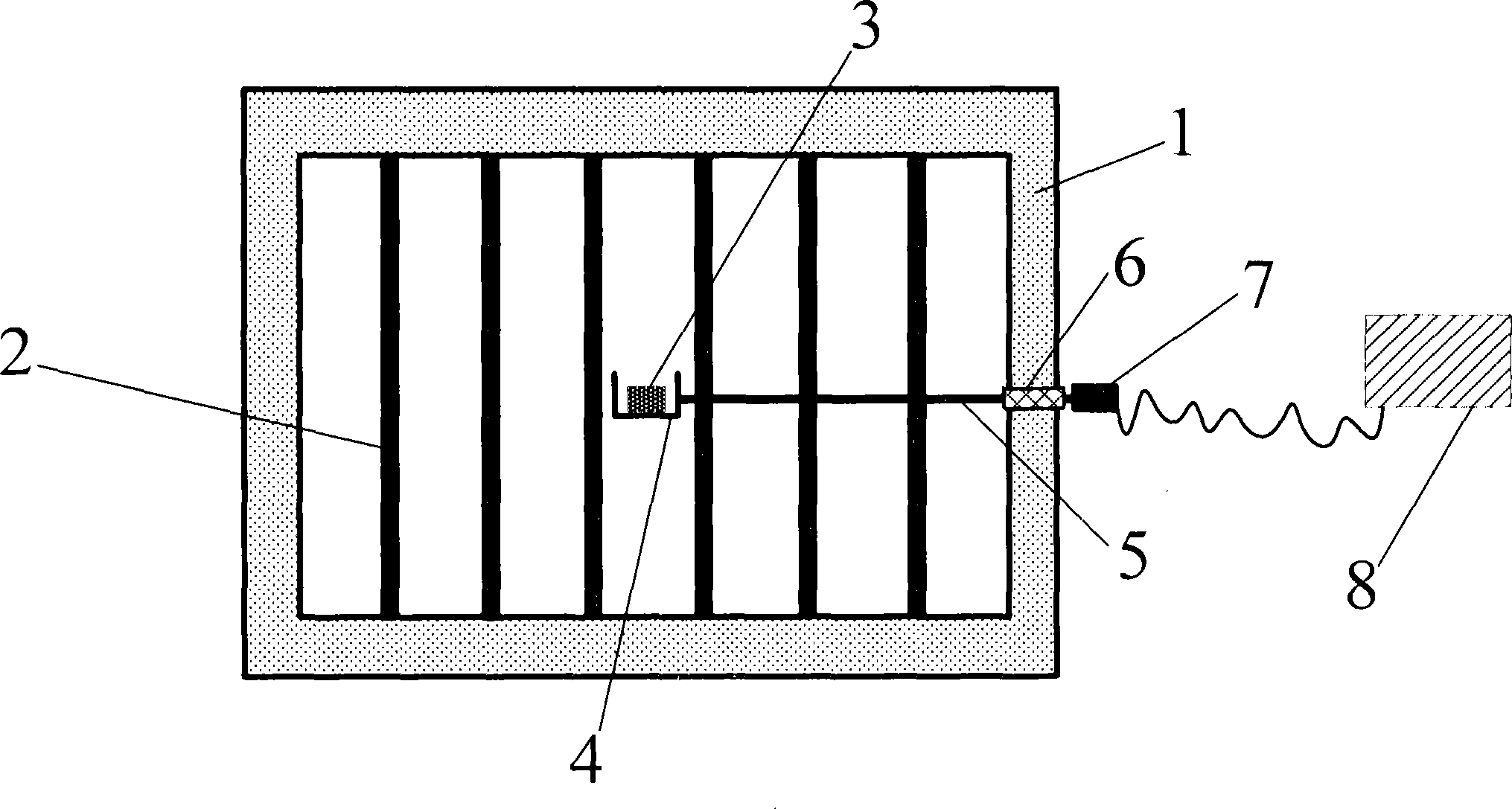

[0023] Such as figure 2 As shown in the side-view schematic diagram of the ultrasonic vibration activation auxiliary sintering box-type resistance furnace ultrasonic device, the ultrasonic vibration activation auxiliary sintering resistance furnace ultrasonic device provided by the present invention is in the form of side installation, and is supported by a hollow cylindrical annular high-temperature alloy steel horn The frame 6 passes through the small hole on the side of the furnace shell 1, the high-temperature alloy steel horn 5 passes through the horn support frame 6, and one end of the horn 5 in the furnace is connected to a high-temperature furnace with a corresponding internal thread on the side through an external thread. The alloy steel crucible 4 is connected to an ultrasonic transducer 7 with a working frequency of 40 kHz by threading at one end outside the hearth of the horn 5 , and the ultrasonic transducer 7 is connected to the ultrasonic generator 8 through wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com