Automatic test device for sounding properties of seacraft hornpipe

An automatic testing device and sea-going ship technology, applied to measuring devices, using electrical devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of cumbersome process, slow calculation speed, low precision, etc., and achieve simple structure of the device and avoid hearing loss Impaired, accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

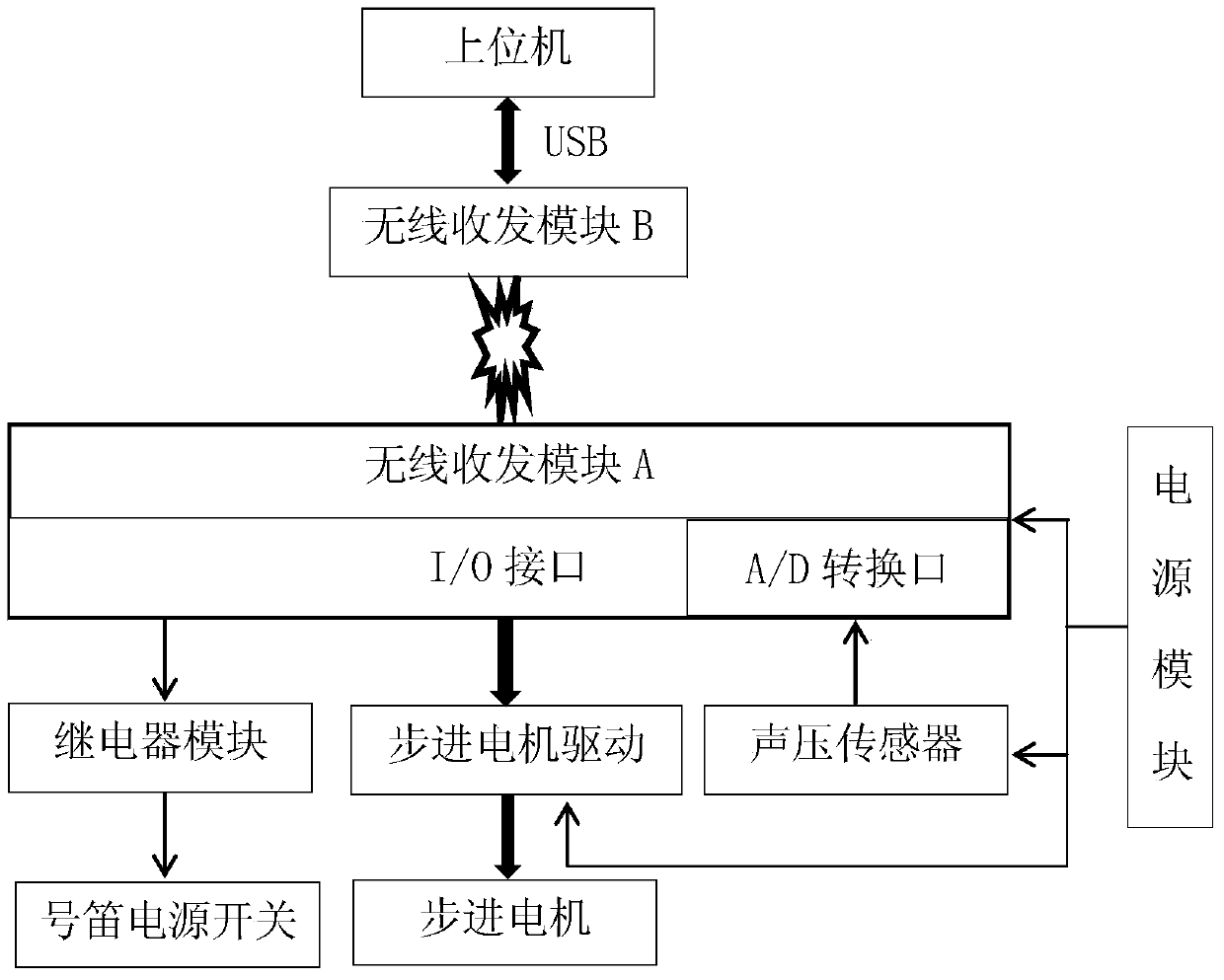

[0044] The sound characteristic testing device of the sea-going whistle of the present invention comprises a frame, an installation platform, a sound pressure sensor, a horizontal rotation mechanism, an azimuth adjustment mechanism, a measurement and control communication unit and a software part of an upper computer.

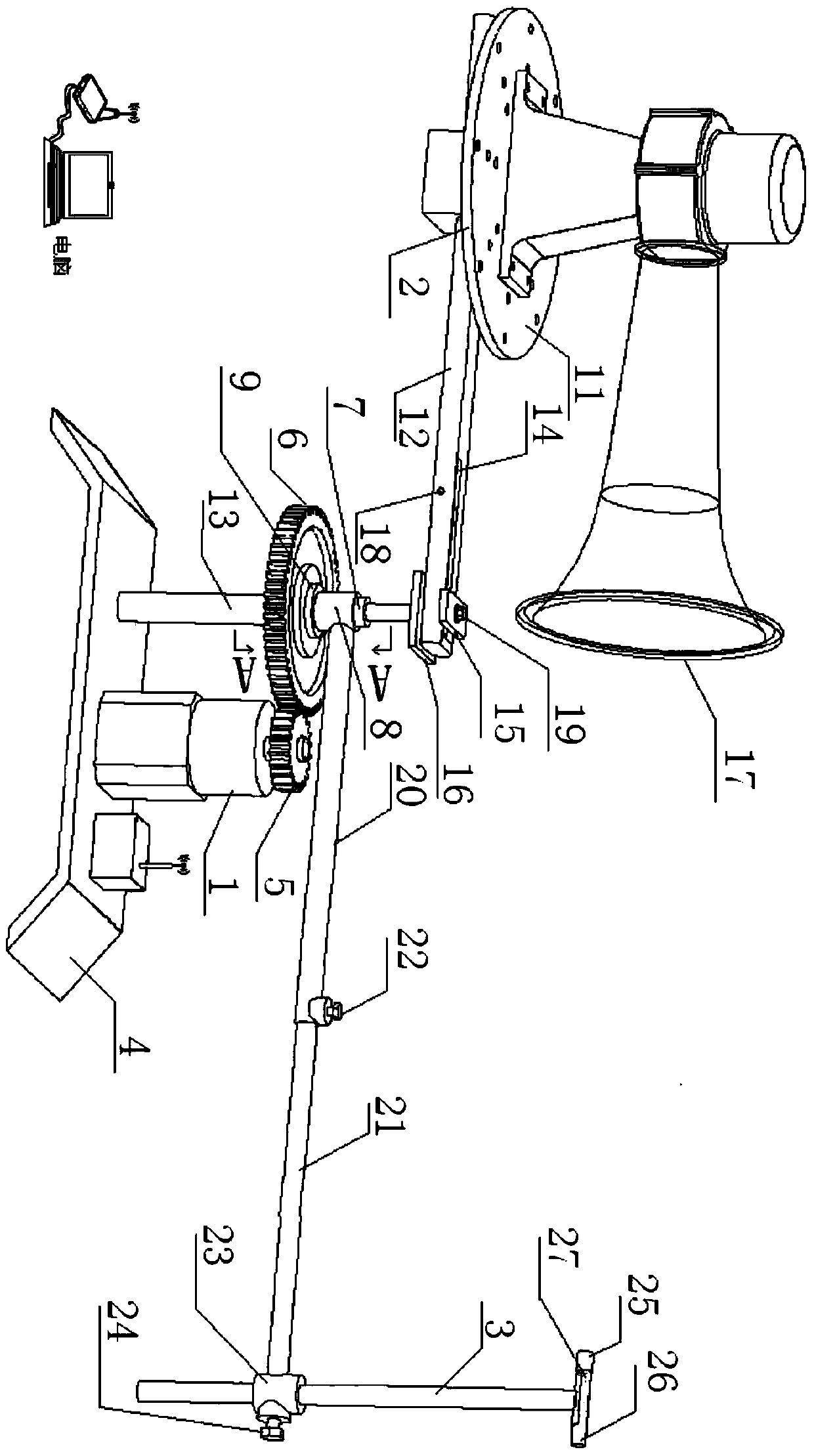

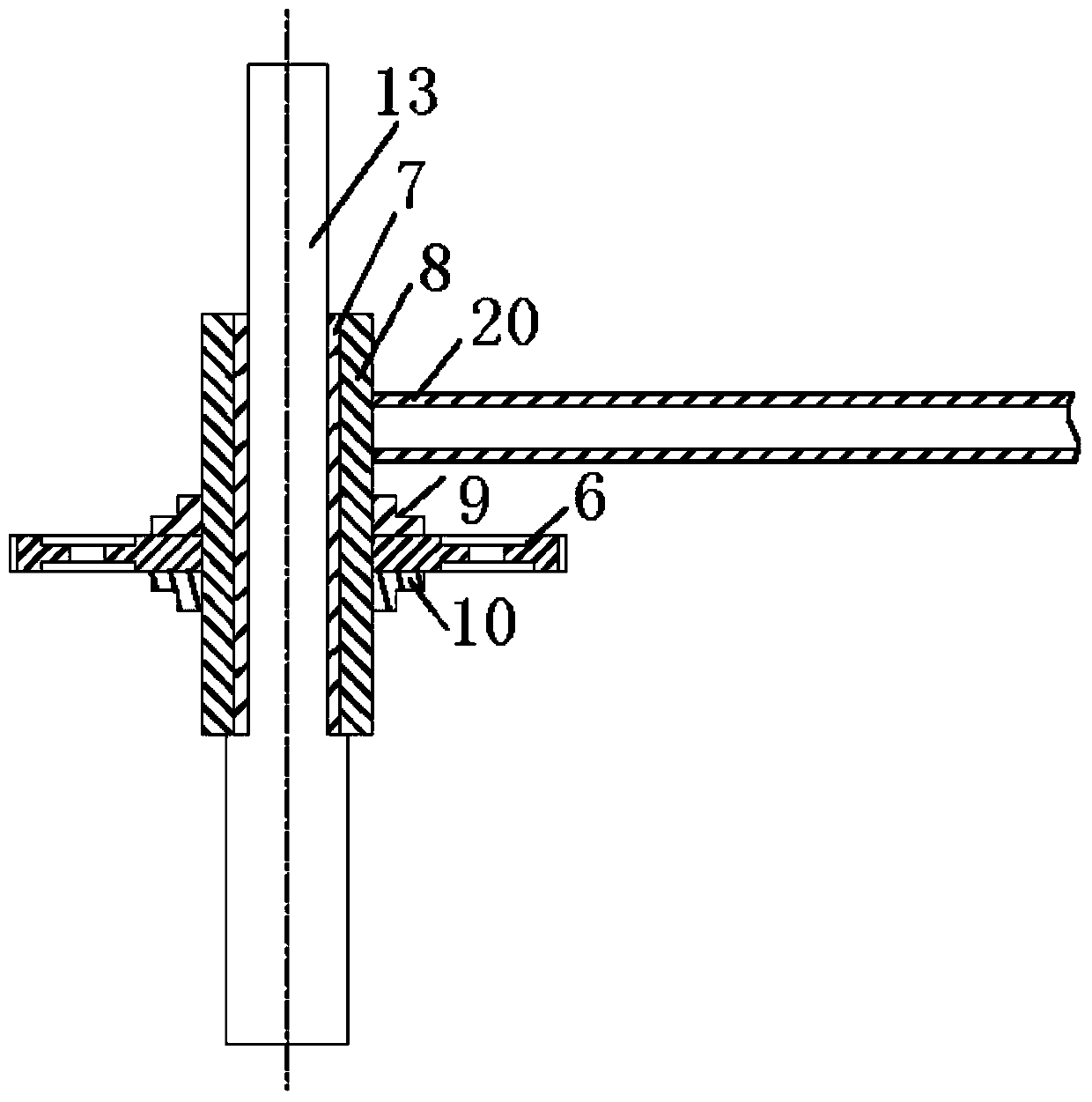

[0045] Such as figure 1 Shown is a schematic diagram of a sound characteristic test device for a sea-going whistle. The frame 4 is placed on a horizontal working surface, and the sound pressure sensor 27 installed on the clamping head 3 is surrounded by the horn mouth of the whistle 17 through a horizontal rotation mechanism and an azimuth adjustment mechanism. Vertical center axis rotation. combine figure 2 As shown, the horizontal rotation mechanism is mainly composed of a stepping motor 1, a driving gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com