Simulation technique based semiconductor device TDDB (time dependent dielectric breakdown) failure testing method

A semiconductor and device technology, applied in the field of TDDB failure testing of semiconductor devices based on simulation technology, can solve the problems of impurity diffusion, pre-test preparation time of expensive test equipment, diffusion into silicon substrate or fixed in silicon dioxide, etc. Time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

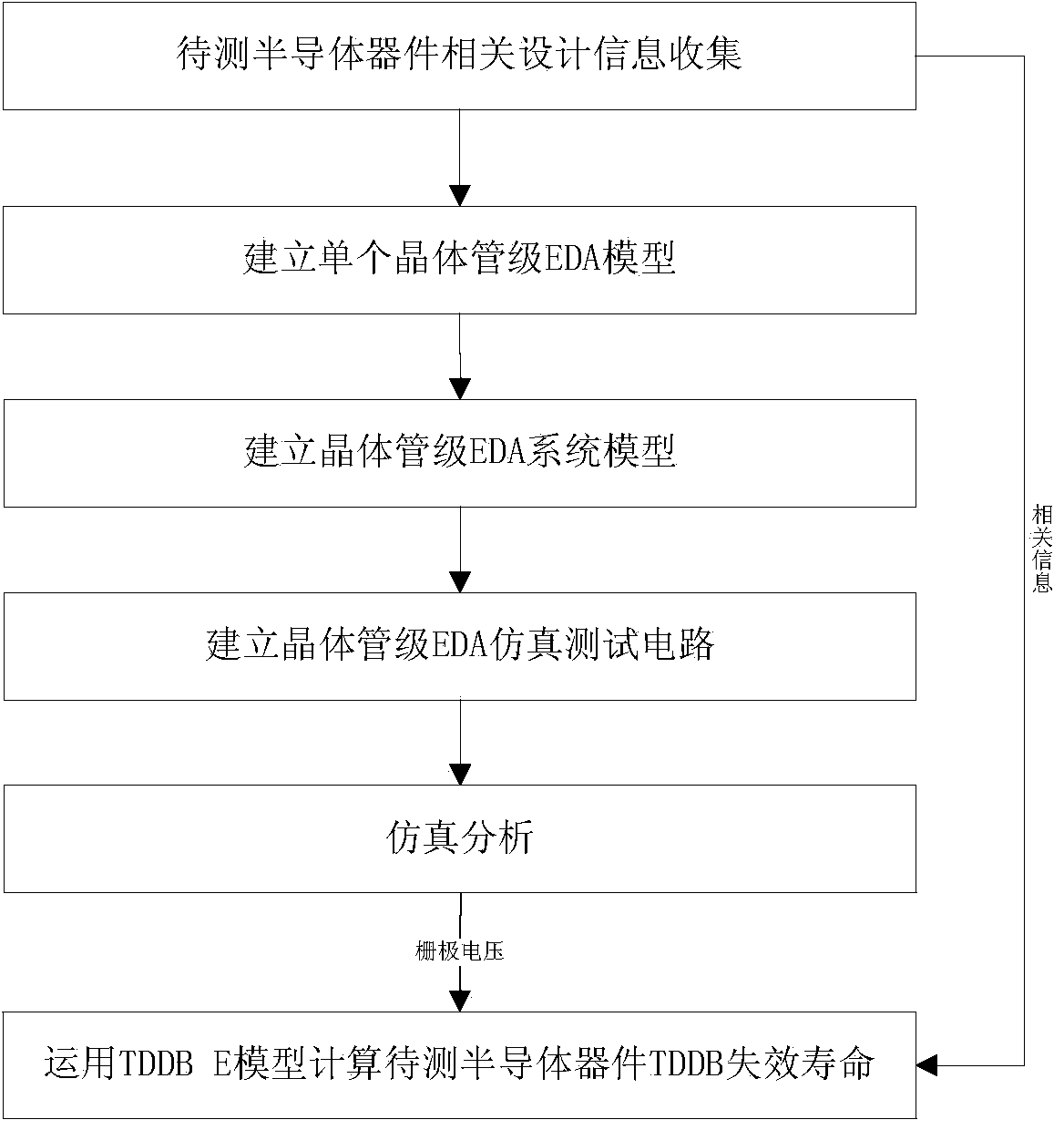

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings:

[0023] Taking "CD4011B" as an example below, the TDDB failure test method for semiconductor devices based on simulation technology described in the present invention is introduced. figure 1 As shown, the steps of this method are:

[0024] Step 1: Collect the known information of "CD4011B", including:

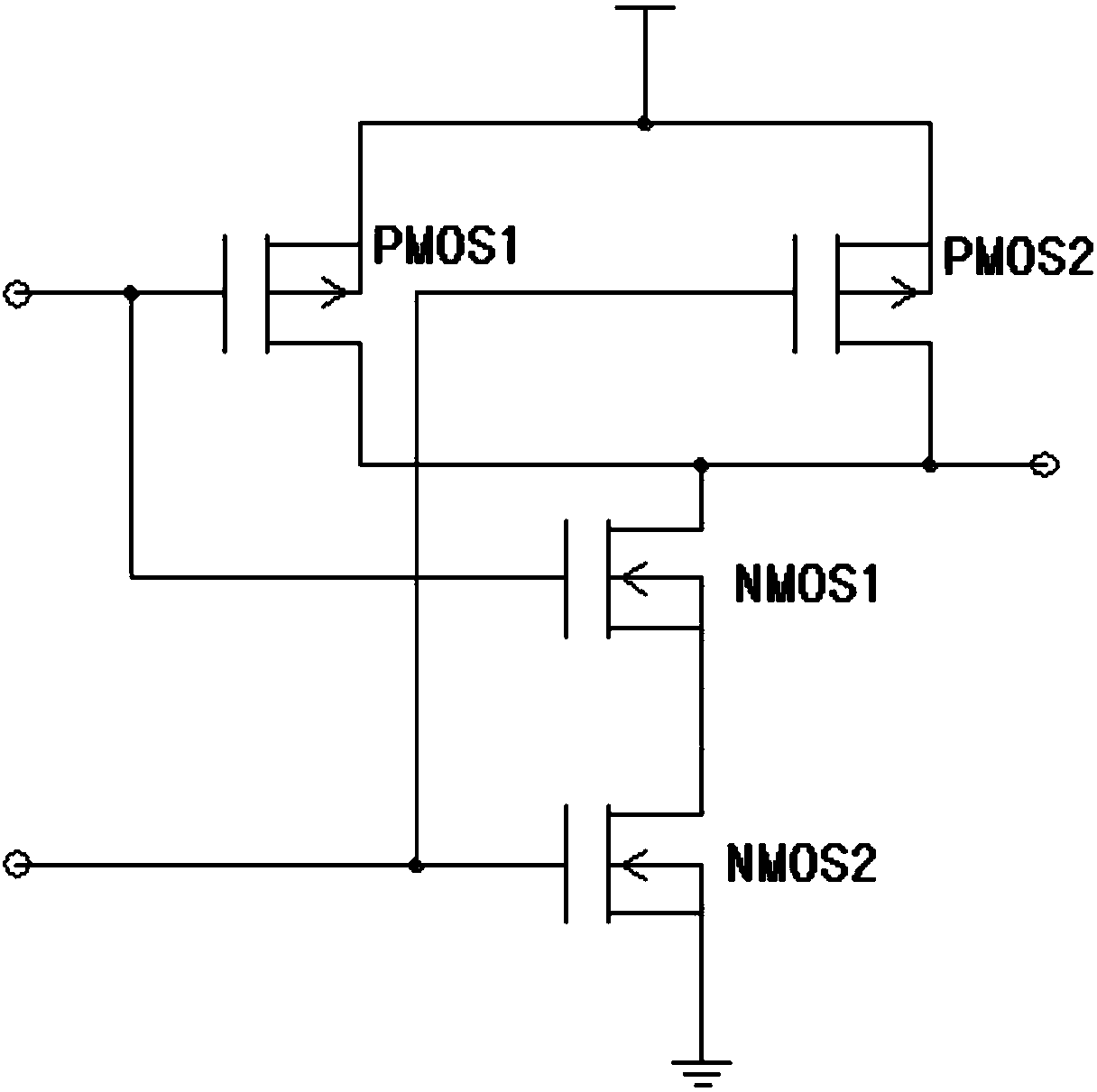

[0025] a) "CD4011B" internal transistor level circuit diagram;

[0026] b) "CD4011B" internal transistor gate oxide breakdown activation energy, electric field breakdown coefficient and electric field acceleration factor;

[0027] c) "CD4011B" internal transistor gate oxide layer thickness;

[0028] d) "CD4011B" internal transistor channel design length, effective width, source area, drain area and other information;

[0029] e) The typical application circuit of the device provided by the "CD4011B" manufacturer, which includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com