The Method of Restoring Medium K Value

A technology for repairing medium and K value, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems of fragile media and achieve the effect of repairing K value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

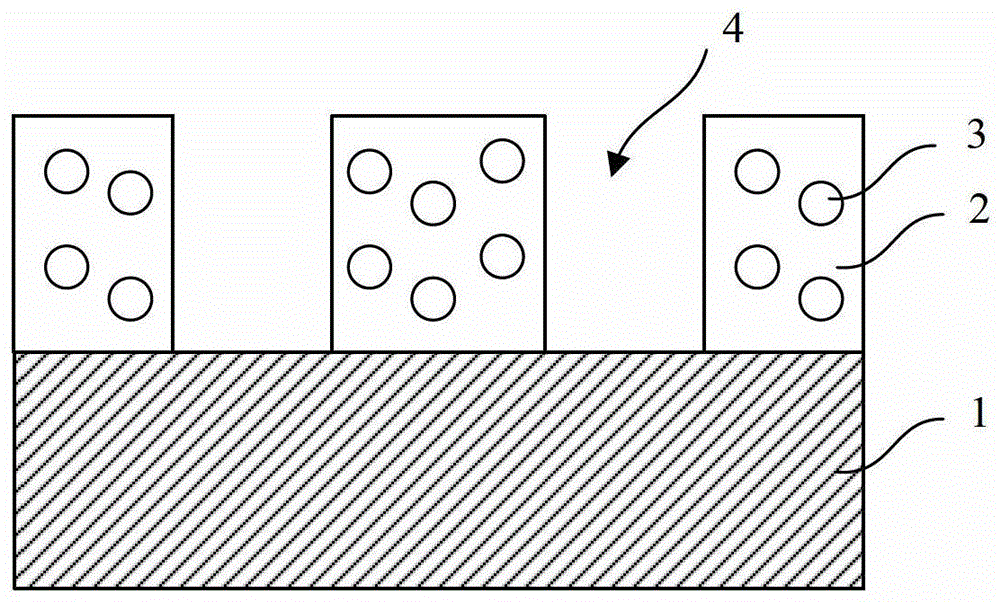

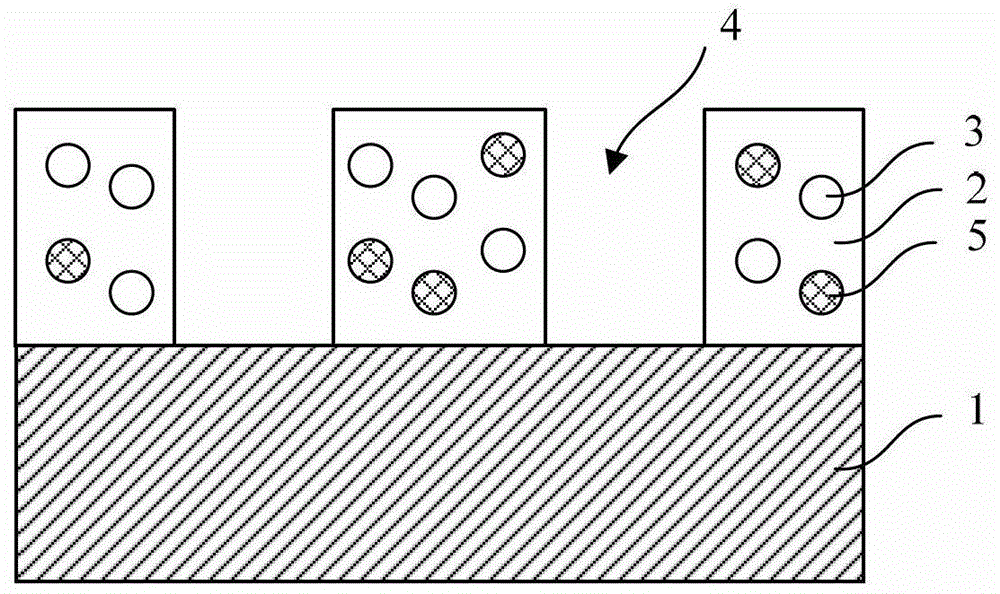

[0039] see Figure 1 to Figure 5 , the present invention provides a kind of method for repairing medium K value, the method for described repairing medium K value at least comprises the following steps:

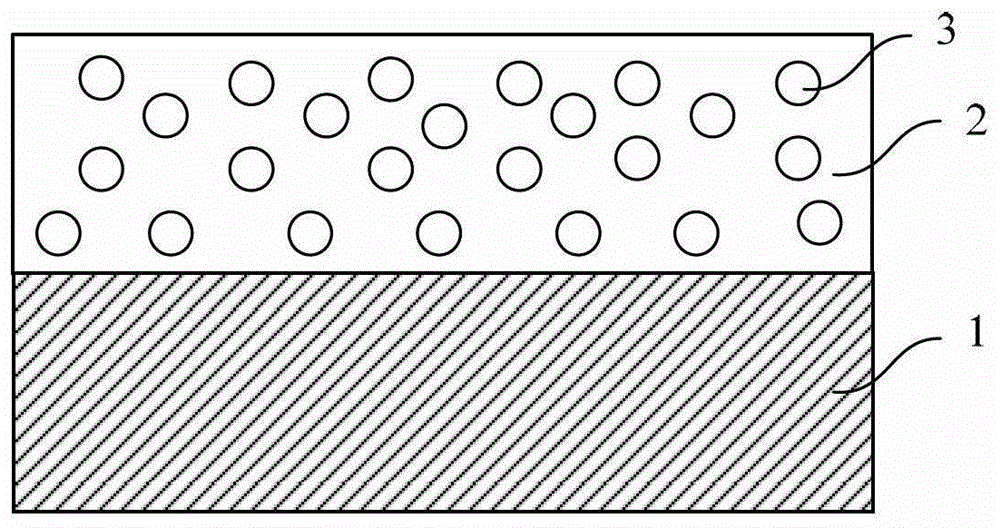

[0040] Step 1), first see the figure 1 , providing a substrate 1 on which a dielectric layer 2 is formed;

[0041] Specifically, the substrate 1 may be a conventional semiconductor substrate such as Si, Ge, SOI, etc., or may be a stacked structure including some devices. The dielectric layer 2 is a low-K medium. In this embodiment, the dielectric layer 2 is preferably a porous ultra-low-K medium; the porous ultra-low-K medium satisfies Kfigure 1 The diagram shows several holes 3 in the dielectric layer 2 . In this embodiment, the dielectric layer 2 is formed by firstly forming a dielectric film layer on the substrate 1 by chemical vapor deposition, and then forming a plurality of holes 3 in the dielectric film layer through porogen and ultraviolet light treatment. It shoul...

Embodiment 2

[0055] Embodiment 2 adopts basically the same solution as Embodiment 1, except that in Embodiment 2, a step of irradiating the dielectric layer with microwaves is also included after the polishing process in the subsequent process flow.

[0056] see Figure 6 to Figure 8 , the present invention provides a kind of method for repairing medium K value, the method for described repairing medium K value at least comprises the following steps:

[0057] Step 1), providing a substrate, and forming a dielectric layer on the substrate;

[0058] Step 2), etching a number of grooves in the dielectric layer, and cleaning to remove the etching residue;

[0059] In step 3), microwaves are used to irradiate the etched dielectric layer.

[0060] It should be pointed out that steps 1) to 3) in this example are the same as steps 1) to 3) in Example 1, and the specific process flow can refer to Example 1 Figure 1 to Figure 5 and related text descriptions, which will not be repeated here.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com