Semiconductor device and method of manufacturing semiconductor device

A semiconductor and nitride semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to solve problems such as gate threshold voltage instability and operational failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

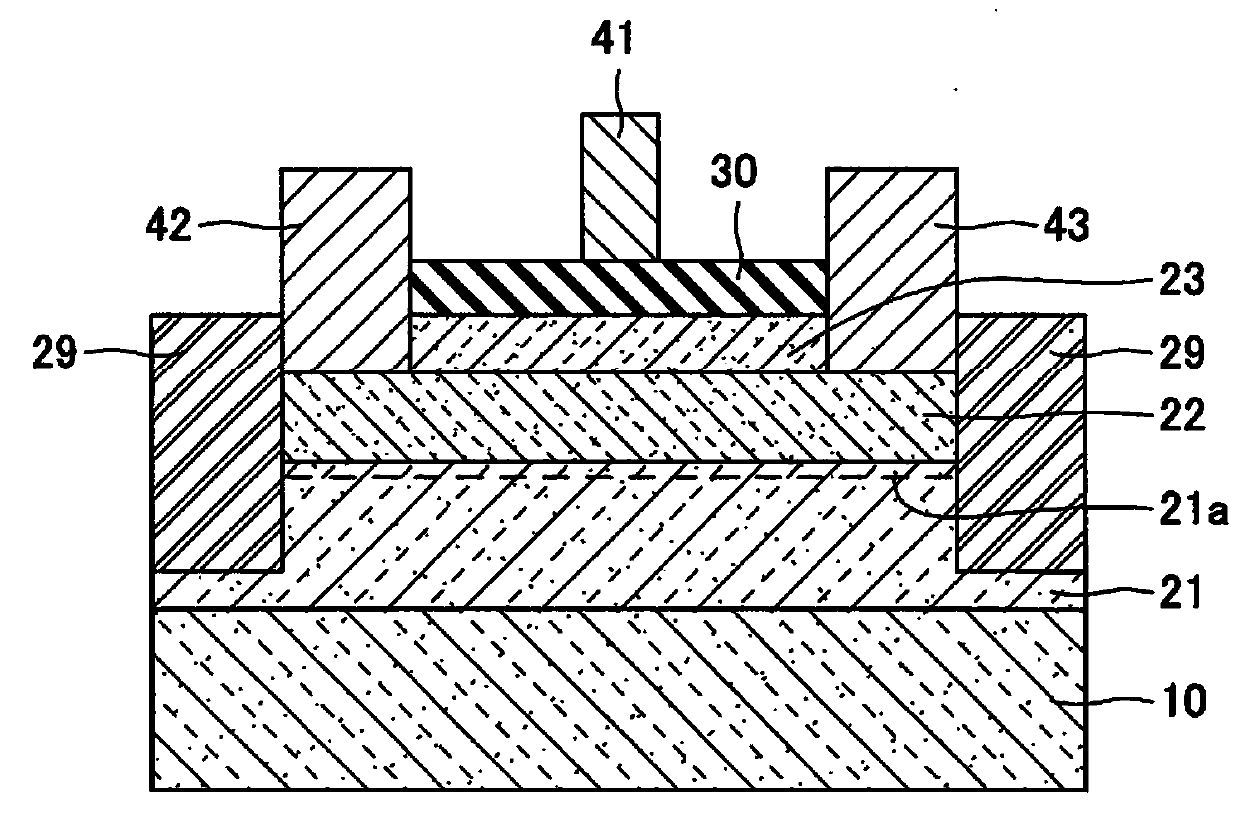

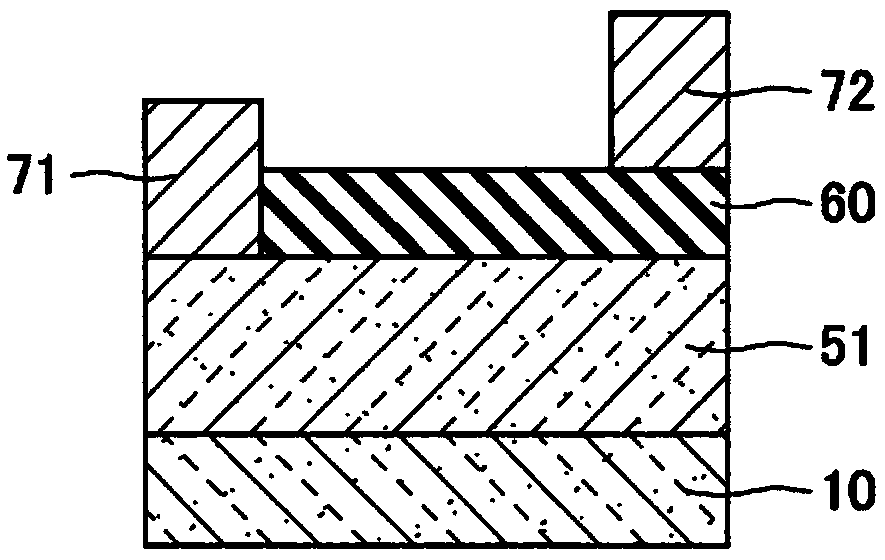

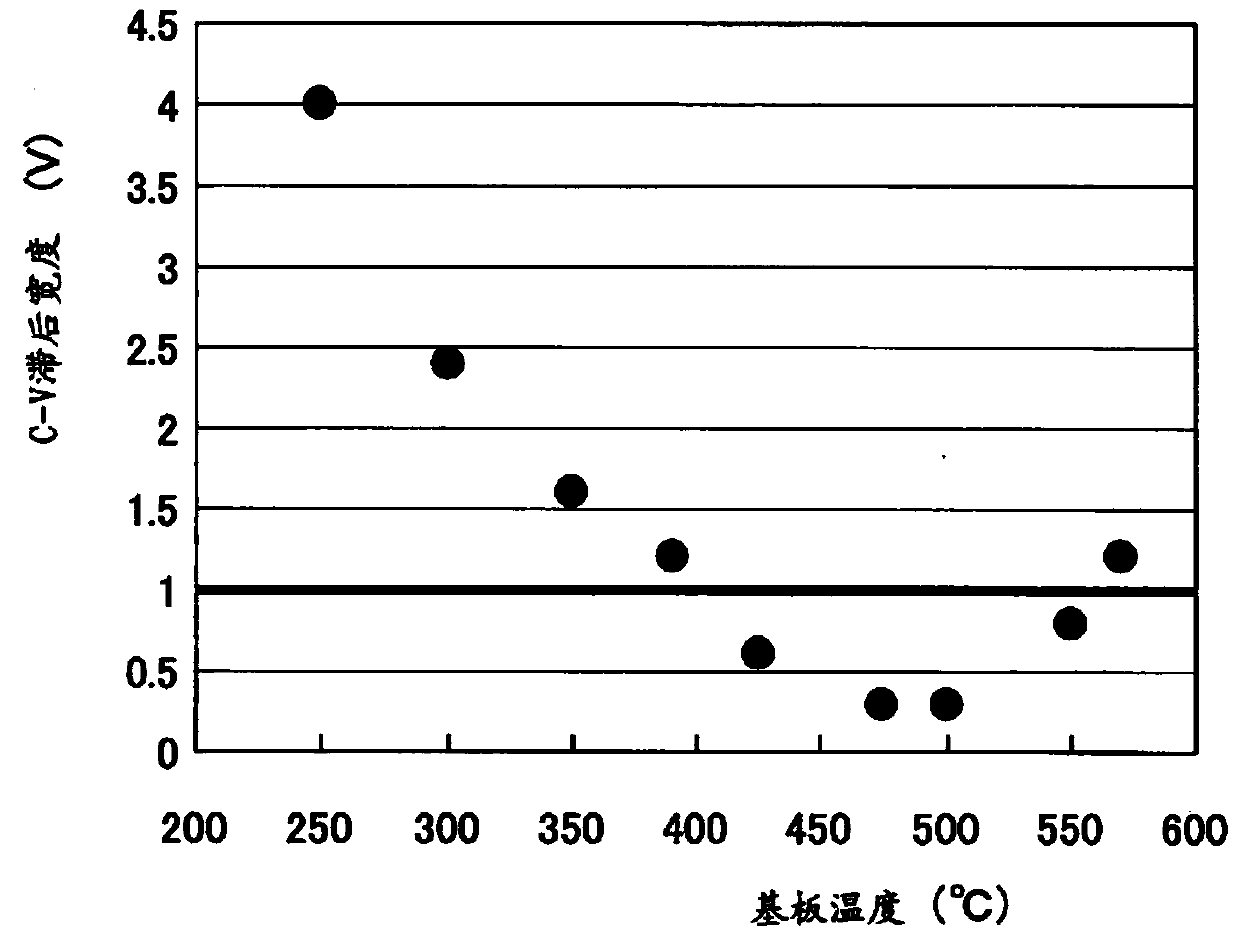

[0042] First, regarding HEMTs that use a nitride semiconductor having a structure in which an insulating film is formed below a gate electrode, there are figure 1 The semiconductor device of the structure shown has been fabricated by having figure 2 The C-V measurement sample of the structure shown was used to investigate the factors causing the gate threshold voltage to become unstable.

[0043] have figure 1 The semiconductor device of the structure has an electron transfer layer 21 , an electron supply layer 22 , and a protective layer 23 laminated on a substrate 10 and made of a nitride semiconductor. Furthermore, on a part of the electron transfer layer 21, the electron supply layer 22, and the protective layer 23, an element separation region 29 for separating elements is formed. On protective layer 23 , insulating layer 30 , source electrode 42 , and drain electrode 43 are formed, and on insulating layer 30 gate electrode 41 is formed. Note that, on the substrate 10...

no. 2 example

[0082] Next, based on Figure 14 A description is given of the second embodiment. The present embodiment has a structure in which insulating layers corresponding to portions where first insulating layer 131 and second insulating layer 132 are formed in the semiconductor device according to the first embodiment are formed by changing film formation conditions. Specifically, the semiconductor device according to this embodiment has a structure in which Al is formed on the protective layer 123 by ALD using TMA and oxygen plasma while gradually lowering the substrate temperature 2 o 3 , to form the insulating layer 230 . Therefore, the insulating layer 230 is formed such that the number of -OH groups is minimized near the interface between the insulating layer 230 and the protective layer 123, and the number of -OH groups gradually increases from the side where the protective layer 123 is formed toward the surface of the insulating layer 230. Increase. Note that the film thick...

no. 3 example

[0087] Semiconductor Device (Third Embodiment)

[0088] Next, based on Figure 15 A description is given of the semiconductor device according to the present embodiment. The semiconductor device according to the present embodiment has an electron transport layer 121 and an electron supply layer 122 which are laminated on a substrate 110 and made of a nitride semiconductor. Furthermore, on a part of the electron transfer layer 121 and the electron supply layer 122, an element separation region 129 for separating elements is formed. On the electron supply layer 122 , the stacked first insulating layer 131 and the second insulating layer 132 are formed together with the source electrode 142 and the drain electrode 143 . Furthermore, on the second insulating layer 132, a gate electrode 141 is formed. Note that, on the substrate 110, a buffer layer may be formed as necessary, and in this case, the above-described nitride semiconductor layer is formed on the buffer layer.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com