Preparation method of solid solution positive material covering surface of fast ionic conductor

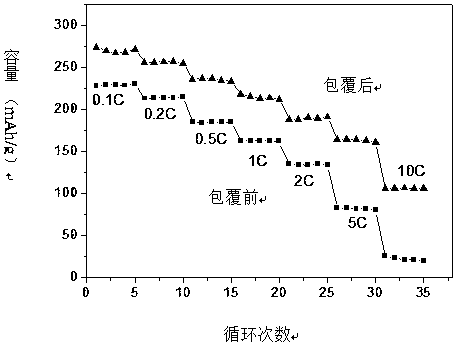

A positive electrode material and surface coating technology, applied in the field of new energy materials, can solve the problems that the rate performance cannot meet the requirements, affect the rate performance of solid solution positive electrode materials, and the low lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: first take by weighing nickel sulfate, cobalt sulfate, manganese sulfate and excessive 20% sodium hydroxide according to stoichiometric ratio, be mixed with concentration and be the mixed solution of 0.1mol / L nickel-cobalt-manganese, nickel, cobalt, manganese in solution The concentration ratio of ions is 1:1:3, and the concentration of sodium hydroxide in the mixed solution is 0.24mol / L. By ultrasonic external field assisted co-precipitation method, the temperature is controlled at 50°C, and the pH value is controlled at 8.0 to prepare the precursor, and then Mixed with lithium carbonate weighed according to the stoichiometric ratio, mechanically activated for 1h, calcined at 400°C for 1h, then calcined at 750°C for 24h, and finally cooled to obtain the layered solid solution positive electrode material Li 1.5 Ni 0.2 co 0.2 mn 0.6 o 2.5 ; Then according to Li 1.2 (Al 0.1 Ti 0.9 ) 2 (PO 4 ) 3 ) stoichiometric ratio to take H 3 PO 4 、TiO 2 、A1 ...

Embodiment 2

[0013] Embodiment 2: first take by weighing nickel sulfate, cobalt sulfate, manganese sulfate and excessive 20% sodium hydroxide according to stoichiometric ratio, be mixed with concentration and be the mixed solution of 1mol / L nickel cobalt manganese, nickel, cobalt, manganese ion in solution The concentration ratio of the solution is 1:1:2, the concentration of sodium hydroxide in the mixed solution is 2.4mol / L, and the ultrasonic field-assisted co-precipitation method is used to control the temperature at 80 ° C and the pH value at 12.0 to prepare the precursor, and then with Lithium carbonate weighed according to the stoichiometric ratio was mixed, mechanically activated for 12 hours, calcined at 400°C for 4 hours, then calcined at 900°C for 8 hours, and finally cooled to obtain the layered solid solution cathode material Li 1.5 Ni 0.25 co 0.25 mn 0.5 o 2.5 ; Then according to Li 1.4 (Al 0.2 Ti 0.8 ) 2 (PO 4 ) 3 ) stoichiometric ratio to take H 3 PO4 、TiO 2 、A1 ...

Embodiment 3

[0015] Embodiment 3: first take by weighing nickel nitrate, cobalt nitrate, manganese nitrate and excessive 20% potassium hydroxide according to stoichiometric ratio, be mixed with concentration and be the mixed solution of 0.5mol / L nickel-cobalt-manganese, nickel, cobalt, manganese in solution The concentration ratio of the ions is 0.25:0.15:0.6, the concentration of sodium hydroxide in the mixed solution is 1.2mol / L, and the ultrasonic field-assisted co-precipitation method is used to control the temperature at 60°C and the pH value at 11.0 to prepare the precursor, and then Mixed with lithium carbonate weighed according to the stoichiometric ratio, mechanically activated for 4 hours, calcined at 400°C for 6 hours, then calcined at 850°C for 12 hours, and finally cooled to obtain the layered solid solution positive electrode material Li 1.5 Ni 0.25 co 0.15 mn 0.6 o 2.5 ; Then according to Li 1.6 (Al 0.3 Ti 0.7 ) 2 (PO 4 ) 3 ) stoichiometric ratio to take H 3 PO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com