Power module group of three-phase power electronic transformer

A power module group and electronic transformer technology, applied in the direction of reversible conversion equipment, etc., can solve the problems of power supply side, unadjustable power factor of the primary side, harmonic pollution of iron core magnetic saturation, etc., to achieve easy design, Improved utilization and reliability of power supply, easy modularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

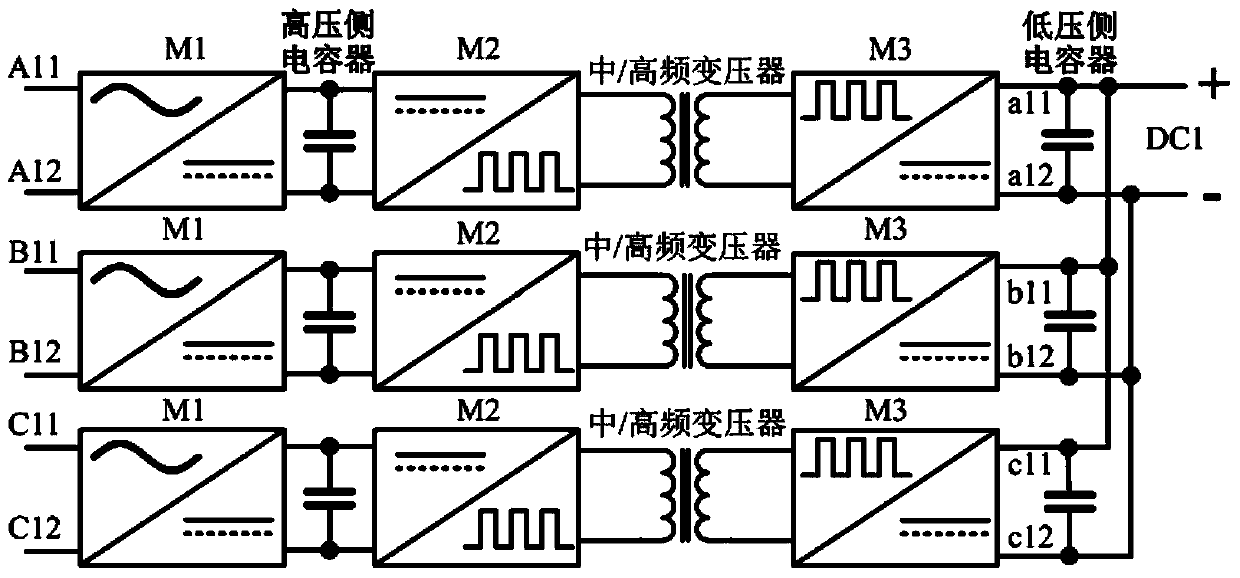

[0118] Embodiment 1, a three-phase power electronic transformer based on a power module unit M.

[0119] In this embodiment, when the number of AC side series connections of the first power module M1 is 3n, each phase uses 3n power module units of M structure to form a power module group, reducing the overall number of power modules and corresponding costs, where n is positive integer.

[0120] Such as Figure 7 as shown, Figure 7 It is a schematic diagram of Embodiment 1 of the three-phase power electronic transformer in this embodiment. For the required high-voltage AC level voltage, the calculated number of AC-side series connections corresponding to the first power module M1 is 3n, where n is a natural number. If the calculated number of AC side series connection corresponding to the first power module M1 is 3n+1 or 3n+2, as shown in the second and third embodiments below.

[0121] For each phase, there are 3n power modules M whose high-voltage AC sides are connected ...

Embodiment 2

[0124] Embodiment 2, a three-phase power electronic transformer based on the power module unit M and the power module unit M / 3.

[0125] If the AC side series connection number of the first power module M1 is 3n+1, and there is no separate DC output requirement, each phase uses 3n power module units with M structure and 1 power module unit with M / 3 structure to form the power The module group reduces the total number of power modules and the corresponding cost, n is a positive integer.

[0126] Such as Figure 8 as shown, Figure 8It is a schematic diagram of the second embodiment of the three-phase power electronic transformer in this embodiment. For the required high-voltage AC level voltage, the calculated number of AC-side series connections corresponding to the first power module M1 is 3n+1 (n is a positive integer).

[0127] In this embodiment, n is a natural number 1, that is, the number of the first power module M1 connected in series on the AC side is four. Theref...

Embodiment 3

[0130] Embodiment 3, a three-phase power electronic transformer based on the power module unit M and the power module unit M / 3.

[0131] If the number of AC side series connection of the first power module M1 is 3n+1 or 3n+2, and there is a requirement for DC output, each phase adopts the corresponding combination of M-structured power module units and M / 3-structured power module units to form a corresponding The power module group meets the corresponding DC output. At the same time, the corresponding combination of the power module unit of the M structure and the power module unit of the M / 3 structure constitutes the corresponding power module group to meet the corresponding AC output, so as to reduce the overall number of power modules And the corresponding cost, n is a positive integer.

[0132] Such as Figure 9 as shown, Figure 9 It is a schematic diagram of the third embodiment of the three-phase power electronic transformer in this embodiment. For the required high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com