A kind of method of using butter enzymolyzate to prepare milk fragrance base material

A technology of butter enzymatic hydrolyzate and milk aroma base, which is applied in the field of food additives, can solve the problems of insufficient aroma intensity and achieve the effects of increased aroma intensity, broad market prospects, and high degree of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

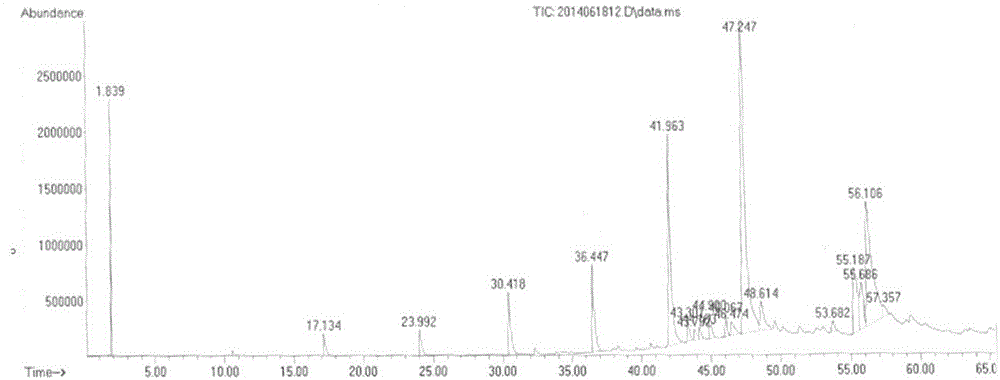

Image

Examples

Embodiment 1

[0055] Embodiment 1: the preparation of milk fragrance base material of the present invention

[0056] The steps of this embodiment are as follows:

[0057] (1) Configure buffer solution

[0058] Prepare a buffer solution with 0.8 parts of disodium hydrogen phosphate, 0.2 parts of potassium dihydrogen phosphate and 24 parts of sterile water.

[0059] (2) emulsification

[0060] Heat and melt 100 parts of butter at 50°C, continue heating to 85°C, sterilize for 15 minutes, then cool to 50°C, then add 24 parts by weight of the buffer solution obtained in step (1), and perform mechanical emulsification of the obtained mixed solution, The speed was 10000 rpm for 5 minutes to obtain an emulsion.

[0061] (3) Enzymolysis reaction

[0062] Add 1 part by weight of compound enzyme solution to the emulsion that step (2) obtains, and described compound enzyme solution is made up of 0.2 part of lipase TL100L, 0.2 part of lipase Palatase20000L, 0.05 part of protease MSD and 1 part by we...

Embodiment 2

[0067] Embodiment 2: the preparation of milk fragrance base material of the present invention

[0068] The steps of this embodiment are as follows:

[0069] (1) Configure buffer solution

[0070] Prepare a buffer solution with 0.5 parts of disodium hydrogen phosphate, 0.5 parts of potassium dihydrogen phosphate and 24 parts of sterile water;

[0071] (2) emulsification

[0072] Heat and melt 100 parts by weight of butter at 40°C, continue heating to 90°C, sterilize for 20 minutes, then cool to 40°C, then add 24 parts by weight of the buffer solution obtained in step (1), and perform mechanical emulsification of the obtained mixed solution, Speed is 12000rpm, lasts 0.5 minutes, thereby obtains emulsion;

[0073] (3) Enzymolysis reaction

[0074] In the emulsion that step (2) obtains, add 1 weight part compound enzyme solution, described compound enzyme solution is made of 0.2 part lipase AY30, 0.2 part lipase MER, 0.2 part lipase 12K, 0.05 part protease AX and 1 weight pa...

Embodiment 3

[0078] Embodiment 3: the preparation of milk fragrance base material of the present invention

[0079] The steps of this embodiment are as follows:

[0080] (1) Configure buffer solution

[0081] Prepare a buffer solution with 1 part of disodium hydrogen phosphate, 0.1 part of potassium dihydrogen phosphate and 24 parts of sterile water;

[0082] (2) emulsification

[0083] Heat and melt 100 parts of butter at 60°C, continue heating to 80°C, sterilize for 30 minutes, then cool to 60°C, then add 24 parts by weight of the buffer solution obtained in step (1), and perform mechanical emulsification of the obtained mixture, Speed is 8000rpm, continues 3 minutes, thereby obtains emulsion;

[0084] (3) Enzymolysis reaction

[0085] In the emulsion that step (2) obtains, add 1 weight part compound enzyme solution, described compound enzyme solution is buffered by 0.2 part lipase Palatase20000L, 0.2 part lipase MER, 0.05 part protease AX, 0.05 part protease MSD and 1 part by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com